What is Global Granite Market?

The global granite market is a significant segment of the natural stone industry, characterized by its widespread use in various applications due to its durability, aesthetic appeal, and versatility. Granite is an igneous rock composed mainly of quartz, feldspar, and mica, which gives it a unique appearance and strength. This natural stone is extracted from quarries worldwide, with major producers including countries like China, India, Brazil, and the United States. The market is driven by the increasing demand for granite in construction and decoration, as it is a preferred material for countertops, flooring, and wall cladding due to its resistance to wear and tear. Additionally, granite's ability to withstand extreme weather conditions makes it suitable for outdoor applications. The global granite market is also influenced by trends in interior design, where natural materials are increasingly favored for their eco-friendly properties and timeless elegance. As urbanization and infrastructure development continue to rise, the demand for granite is expected to grow, making it a vital component of the construction industry. The market's growth is further supported by advancements in quarrying and processing technologies, which enhance the quality and availability of granite products.

Black Granite, Muscovite Granite, Hornbright Granite, Other in the Global Granite Market:

Black granite, muscovite granite, hornblende granite, and other varieties each have distinct characteristics that cater to different needs within the global granite market. Black granite, known for its sleek and sophisticated appearance, is highly sought after for both residential and commercial projects. Its deep, rich color adds a touch of elegance to any space, making it a popular choice for countertops, flooring, and wall cladding. Black granite is also favored for its ability to hide stains and scratches, making it a practical option for high-traffic areas. Muscovite granite, on the other hand, is characterized by its light color and shimmering mica inclusions. This type of granite is often used in spaces that require a brighter, more open feel. Its reflective properties can enhance natural light, making it ideal for kitchens and bathrooms. Muscovite granite is also valued for its durability and resistance to heat, making it suitable for various applications. Hornblende granite, with its dark, speckled appearance, offers a unique aesthetic that is both bold and versatile. This type of granite is often used in outdoor applications, such as paving and landscaping, due to its ability to withstand harsh weather conditions. Its robust nature also makes it a preferred choice for monuments and statuary, where longevity is essential. Other varieties of granite, which may include exotic colors and patterns, provide additional options for designers and architects looking to create distinctive and personalized spaces. These granites can be used to make a statement in both residential and commercial settings, offering a wide range of possibilities for customization. The global granite market benefits from the diversity of granite types available, allowing for a broad spectrum of applications and design opportunities. As consumer preferences continue to evolve, the demand for unique and high-quality granite products is expected to rise, further driving the market's growth.

Construction and Decoration, Monument and Statuary, Furniture, Others in the Global Granite Market:

The global granite market plays a crucial role in various sectors, particularly in construction and decoration, monuments and statuary, furniture, and other applications. In construction and decoration, granite is a preferred material due to its durability, aesthetic appeal, and versatility. It is commonly used for countertops, flooring, and wall cladding, providing a luxurious and timeless look to residential and commercial spaces. Granite's resistance to wear and tear, as well as its ability to withstand extreme weather conditions, makes it an ideal choice for both indoor and outdoor applications. In the realm of monuments and statuary, granite's robustness and ability to retain its polish over time make it a favored material for creating lasting tributes. Its natural beauty and variety of colors allow for the creation of unique and personalized monuments that stand the test of time. Granite is also used in the furniture industry, where it is incorporated into tabletops, vanities, and other pieces to add a touch of elegance and sophistication. Its durability ensures that furniture made with granite can withstand daily use while maintaining its appearance. Beyond these applications, granite is used in various other areas, such as in the creation of decorative items, garden features, and even in the construction of bridges and roads. The versatility of granite, combined with its natural beauty and strength, makes it a valuable material in numerous industries. As the demand for high-quality and sustainable materials continues to grow, the global granite market is poised to expand, offering a wide range of possibilities for innovation and design.

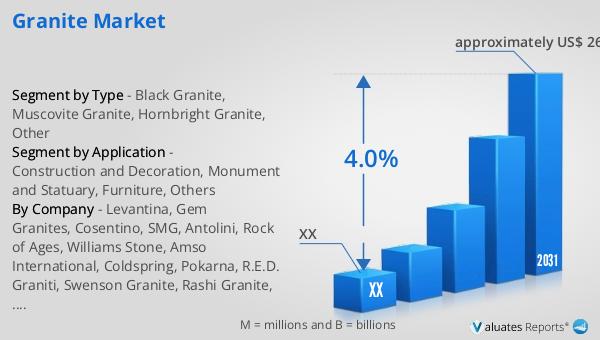

Global Granite Market Outlook:

In 2024, the global granite market was valued at approximately US$ 19,840 million. Looking ahead, it is projected to reach around US$ 26,000 million by 2031, reflecting a compound annual growth rate (CAGR) of 4.0% during the forecast period from 2025 to 2031. This growth is indicative of the increasing demand for granite across various sectors, driven by its durability, aesthetic appeal, and versatility. The construction industry, in particular, is a major contributor to this growth, as granite is a preferred material for countertops, flooring, and wall cladding. Additionally, the trend towards sustainable and eco-friendly materials in interior design further supports the market's expansion. The rising urbanization and infrastructure development worldwide also play a significant role in driving the demand for granite, as it is used in both residential and commercial projects. Furthermore, advancements in quarrying and processing technologies have improved the quality and availability of granite products, making them more accessible to a broader range of consumers. As the global granite market continues to evolve, it presents numerous opportunities for innovation and growth, catering to the diverse needs of consumers and industries alike.

| Report Metric | Details |

| Report Name | Granite Market |

| Forecasted market size in 2031 | approximately US$ 26000 million |

| CAGR | 4.0% |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Levantina, Gem Granites, Cosentino, SMG, Antolini, Rock of Ages, Williams Stone, Amso International, Coldspring, Pokarna, R.E.D. Graniti, Swenson Granite, Rashi Granite, KSG, Tanhat Mining, UMGG, Kangli Stone, Wanlistone, Yinlian Stone, Xinfeng Group |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |