What is Global SCR Denitrification Catalyst Market?

The Global SCR Denitrification Catalyst Market is a crucial segment within the environmental technology industry, focusing on reducing nitrogen oxides (NOx) emissions from industrial processes. Selective Catalytic Reduction (SCR) is a method that uses a catalyst to convert NOx into nitrogen and water, which are harmless to the environment. This technology is essential for industries that produce significant NOx emissions, such as power generation, cement production, and transportation. The catalysts used in SCR systems are typically composed of materials like vanadium, tungsten, and titanium, which facilitate the chemical reaction needed to reduce NOx emissions effectively. The market for these catalysts is driven by stringent environmental regulations worldwide, aiming to curb air pollution and its adverse effects on human health and the environment. As industries strive to comply with these regulations, the demand for efficient and reliable SCR denitrification catalysts continues to grow. This market is characterized by technological advancements, with companies investing in research and development to enhance the performance and durability of their catalysts. Overall, the Global SCR Denitrification Catalyst Market plays a vital role in promoting cleaner industrial practices and contributing to global efforts to combat air pollution.

Honeycomb Catalyst, Plate Catalyst, Corrugated Catalyst in the Global SCR Denitrification Catalyst Market:

In the realm of the Global SCR Denitrification Catalyst Market, three primary types of catalysts are widely used: Honeycomb Catalyst, Plate Catalyst, and Corrugated Catalyst. Each of these catalysts has unique characteristics and applications, making them suitable for different industrial needs. The Honeycomb Catalyst is perhaps the most commonly used type due to its high surface area and excellent gas flow properties. It consists of a ceramic or metal substrate with a honeycomb structure, which allows for efficient contact between the exhaust gases and the catalyst surface. This design maximizes the conversion of NOx into nitrogen and water, making it highly effective in reducing emissions. Honeycomb Catalysts are particularly favored in applications where space is limited, as their compact design allows for easy integration into existing systems. On the other hand, Plate Catalysts are characterized by their flat, plate-like structure. They are typically made from metal or ceramic materials and are coated with catalytic substances. Plate Catalysts offer a larger surface area compared to Honeycomb Catalysts, which can enhance the efficiency of the SCR process. They are often used in applications where high NOx conversion rates are required, such as in large-scale industrial plants. The flat design of Plate Catalysts also allows for easy cleaning and maintenance, which is a significant advantage in industries with high particulate emissions. Corrugated Catalysts, as the name suggests, feature a corrugated or wavy structure. This design increases the turbulence of the gas flow, improving the contact between the gases and the catalyst surface. Corrugated Catalysts are known for their durability and resistance to thermal shock, making them suitable for high-temperature applications. They are often used in industries where the exhaust gases contain high levels of particulates or other contaminants, as their robust design can withstand harsh operating conditions. In summary, each type of catalyst within the Global SCR Denitrification Catalyst Market offers distinct advantages, and the choice of catalyst depends on the specific requirements of the application. Whether it's the compact and efficient Honeycomb Catalyst, the high-surface-area Plate Catalyst, or the durable Corrugated Catalyst, these technologies play a crucial role in reducing NOx emissions and promoting cleaner industrial practices.

Power Plant, Cement Plant, Steel Plant, Glass Industry, Chemical Industry, Transportation, Other in the Global SCR Denitrification Catalyst Market:

The Global SCR Denitrification Catalyst Market finds extensive usage across various industries, each with its unique requirements and challenges. In power plants, SCR catalysts are essential for reducing NOx emissions from the combustion of fossil fuels. Power plants are significant contributors to air pollution, and the implementation of SCR technology helps them comply with stringent environmental regulations. The catalysts used in power plants are designed to withstand high temperatures and large volumes of exhaust gases, ensuring efficient NOx reduction. In cement plants, the production process involves high-temperature kilns that emit substantial amounts of NOx. SCR catalysts are integrated into the exhaust systems of these kilns to minimize emissions and improve air quality. The harsh operating conditions in cement plants require catalysts that are durable and resistant to thermal shock. Similarly, in steel plants, the production process generates significant NOx emissions, particularly during the combustion of coke and other fuels. SCR catalysts are used to treat the exhaust gases, reducing emissions and helping steel manufacturers meet environmental standards. The glass industry also benefits from SCR technology, as the melting and refining processes produce NOx emissions. The use of SCR catalysts in glass manufacturing helps reduce these emissions, contributing to cleaner production practices. In the chemical industry, various processes, such as the production of nitric acid and fertilizers, generate NOx emissions. SCR catalysts are employed to treat these emissions, ensuring compliance with environmental regulations and minimizing the industry's impact on air quality. The transportation sector, particularly diesel engines, is another significant source of NOx emissions. SCR technology is widely used in vehicles to reduce emissions and meet stringent emission standards. The catalysts used in transportation are designed to be compact and efficient, ensuring optimal performance in a variety of operating conditions. Finally, other industries, such as waste incineration and oil refining, also utilize SCR catalysts to manage NOx emissions. These industries face unique challenges, such as high particulate levels and corrosive environments, which require specialized catalyst designs. Overall, the Global SCR Denitrification Catalyst Market plays a vital role in helping various industries reduce their environmental impact and comply with regulatory requirements.

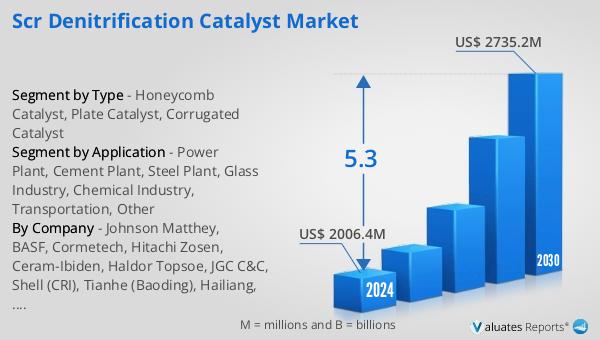

Global SCR Denitrification Catalyst Market Outlook:

In 2024, the global market for SCR Denitrification Catalysts was valued at approximately USD 2,076 million. Looking ahead, it is projected to grow significantly, reaching around USD 3,044 million by 2031. This growth is expected to occur at a compound annual growth rate (CAGR) of 5.7% during the forecast period from 2025 to 2031. The market is characterized by a few key players who dominate the landscape. The top three producers collectively account for about 27% of the market share, with Tianhe Baoding emerging as the largest producer, holding an 8% share. This indicates a competitive market environment where leading companies are striving to maintain their positions while new entrants seek to capture market share. The growth of the SCR Denitrification Catalyst Market is driven by increasing environmental awareness and stringent regulations aimed at reducing air pollution. Industries across the globe are investing in SCR technology to comply with these regulations and minimize their environmental footprint. As a result, the demand for efficient and reliable SCR catalysts is expected to rise, creating opportunities for both established players and new entrants in the market. The market's expansion is also supported by technological advancements, with companies focusing on developing innovative catalyst designs that offer improved performance and durability. Overall, the Global SCR Denitrification Catalyst Market is poised for significant growth, driven by regulatory pressures and the need for cleaner industrial practices.

| Report Metric | Details |

| Report Name | SCR Denitrification Catalyst Market |

| Forecasted market size in 2031 | approximately US$ 3044 million |

| CAGR | 5.7% |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Johnson Matthey, BASF, Cormetech, Hitachi Zosen, Ceram-Ibiden, Haldor Topsoe, JGC C&C, Shell (CRI), Tianhe (Baoding), Hailiang, Datang Environmental, Guodian Longyuan, Jiangsu Wonder, Tuna, Dongfang KWH, Chongqing Yuanda, Gem Sky, Beijing Denox, CHEC |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |