What is Global Saw Wire Market?

The Global Saw Wire Market is a crucial segment within the industrial sector, primarily focused on the production and utilization of saw wires. These wires are essential tools used in cutting and slicing hard materials such as silicon, sapphire, and other semiconductors. The market has witnessed significant growth due to the increasing demand for electronic devices, solar panels, and other high-tech applications that require precise and efficient cutting solutions. Saw wires are typically made from high-strength steel and are coated with abrasive materials like diamond or other hard substances to enhance their cutting capabilities. The market is characterized by continuous innovation and technological advancements aimed at improving the efficiency, durability, and cost-effectiveness of saw wires. As industries continue to evolve and demand more sophisticated materials, the Global Saw Wire Market is expected to expand further, driven by the need for high-precision cutting tools in various applications. The market's growth is also supported by the increasing investments in research and development, which aim to enhance the performance and lifespan of saw wires, making them more suitable for a wide range of industrial applications.

Electroplated Wire, Resin Wire in the Global Saw Wire Market:

Electroplated wire and resin wire are two prominent types of saw wires used in the Global Saw Wire Market, each with distinct characteristics and applications. Electroplated wire is typically made by coating a steel core with a layer of abrasive material, such as diamond particles, through an electroplating process. This type of wire is known for its high precision and efficiency in cutting hard materials. The electroplating process ensures that the abrasive particles are uniformly distributed on the wire's surface, providing consistent cutting performance. Electroplated wires are widely used in industries that require precise cutting, such as the semiconductor and photovoltaic industries. They are particularly effective in slicing silicon wafers, which are essential components in solar panels and electronic devices. The durability and sharpness of electroplated wires make them a preferred choice for applications that demand high precision and minimal material wastage. On the other hand, resin wire is made by embedding abrasive particles in a resin matrix, which is then applied to a steel core. This type of wire is known for its flexibility and ability to cut through materials with varying hardness levels. Resin wires are often used in applications where a smoother finish is required, as the resin matrix can provide a cushioning effect that reduces the risk of chipping or cracking the material being cut. This makes resin wires suitable for slicing brittle materials like sapphire, which is commonly used in LED manufacturing and other high-tech applications. The flexibility of resin wires also allows them to adapt to different cutting conditions, making them a versatile option for various industrial applications. Both electroplated and resin wires have their advantages and limitations, and the choice between them often depends on the specific requirements of the cutting application. Electroplated wires are favored for their precision and efficiency, while resin wires are chosen for their flexibility and ability to produce smooth finishes. As the Global Saw Wire Market continues to grow, manufacturers are investing in research and development to enhance the performance of both types of wires. Innovations in coating technologies and materials are being explored to improve the cutting speed, durability, and cost-effectiveness of saw wires. Additionally, environmental considerations are becoming increasingly important, with efforts being made to develop more sustainable and eco-friendly manufacturing processes for saw wires. In conclusion, electroplated wire and resin wire are essential components of the Global Saw Wire Market, each offering unique benefits for different cutting applications. The ongoing advancements in technology and materials are expected to drive further growth and innovation in this market, meeting the evolving needs of industries that rely on high-precision cutting tools. As demand for electronic devices, solar panels, and other high-tech products continues to rise, the importance of efficient and reliable saw wires will only increase, making them a critical element in the global industrial landscape.

Silicon Slicing, Sapphire Slicing, Others in the Global Saw Wire Market:

The Global Saw Wire Market plays a vital role in various industries, particularly in the areas of silicon slicing, sapphire slicing, and other applications. Silicon slicing is one of the primary uses of saw wires, as silicon wafers are fundamental components in the manufacturing of semiconductors and solar panels. The precision and efficiency of saw wires are crucial in this process, as they ensure that the silicon wafers are cut to the exact specifications required for optimal performance. The demand for silicon slicing is driven by the growing need for electronic devices and renewable energy solutions, making it a significant segment within the Global Saw Wire Market. Sapphire slicing is another important application of saw wires, particularly in the production of LED lights and other high-tech products. Sapphire is a hard and brittle material, requiring specialized cutting tools to achieve the desired shape and size without causing damage. Saw wires, especially resin wires, are well-suited for this task due to their ability to provide a smooth finish and reduce the risk of chipping or cracking. The increasing demand for energy-efficient lighting solutions and advanced electronic devices has led to a rise in sapphire slicing activities, further boosting the Global Saw Wire Market. In addition to silicon and sapphire slicing, saw wires are used in various other applications across different industries. These include the cutting of other semiconductor materials, ceramics, and even some metals. The versatility of saw wires makes them an indispensable tool in industries that require precise and efficient cutting solutions. As technology continues to advance, the range of materials that can be effectively sliced using saw wires is expected to expand, opening up new opportunities for growth in the Global Saw Wire Market. The usage of saw wires in these areas highlights the importance of continuous innovation and development within the market. Manufacturers are constantly seeking ways to improve the performance and durability of saw wires, ensuring that they can meet the evolving needs of industries that rely on high-precision cutting tools. This includes exploring new materials and coating technologies that can enhance the cutting speed and efficiency of saw wires, as well as developing more sustainable manufacturing processes to reduce the environmental impact of production. Overall, the Global Saw Wire Market is a dynamic and rapidly evolving sector, driven by the increasing demand for high-tech products and renewable energy solutions. The usage of saw wires in silicon slicing, sapphire slicing, and other applications underscores their critical role in modern industrial processes. As industries continue to innovate and develop new technologies, the need for efficient and reliable saw wires will only grow, making them an essential component of the global industrial landscape.

Global Saw Wire Market Outlook:

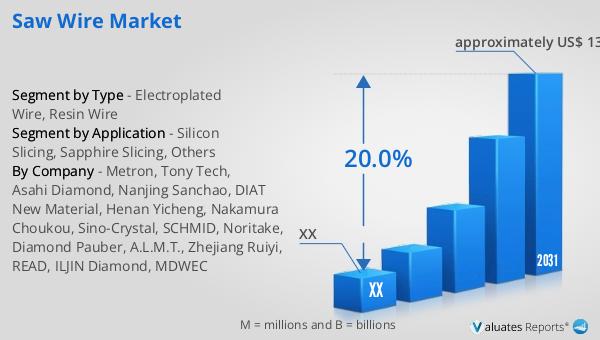

In 2024, the global market size of the Saw Wire industry was valued at approximately US$ 3,899 million. It is projected to experience significant growth, reaching an estimated value of around US$ 13,740 million by 2031. This growth trajectory reflects a robust compound annual growth rate (CAGR) of 20.0% during the forecast period from 2025 to 2031. China stands out as the leading producer in this market, commanding a substantial market share of about 80%. This dominance is attributed to the country's advanced manufacturing capabilities and the presence of key industry players. Among the top manufacturers in the Saw Wire industry are Metron, Tony Tech, Nanjing Sanchao, DIAT New Material, and Henan Yicheng. These companies collectively hold approximately 65% of the market share, underscoring their significant influence and contribution to the industry's growth. The market's expansion is driven by the increasing demand for high-precision cutting tools in various applications, including electronics, solar panels, and other high-tech industries. As the market continues to evolve, these leading manufacturers are expected to play a crucial role in shaping the future of the Saw Wire industry, leveraging their expertise and innovation to meet the growing needs of global industries.

| Report Metric | Details |

| Report Name | Saw Wire Market |

| Forecasted market size in 2031 | approximately US$ 13740 million |

| CAGR | 20.0% |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Metron, Tony Tech, Asahi Diamond, Nanjing Sanchao, DIAT New Material, Henan Yicheng, Nakamura Choukou, Sino-Crystal, SCHMID, Noritake, Diamond Pauber, A.L.M.T., Zhejiang Ruiyi, READ, ILJIN Diamond, MDWEC |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |