What is Global Vacuum Coating Machines Market?

The Global Vacuum Coating Machines Market is a dynamic and rapidly evolving sector that plays a crucial role in various industries by providing advanced coating solutions. These machines are designed to apply thin films or coatings onto surfaces in a vacuum environment, which enhances the properties of the substrate, such as durability, corrosion resistance, and aesthetic appeal. The market encompasses a wide range of technologies and applications, catering to industries like electronics, automotive, optics, and more. The demand for vacuum coating machines is driven by the need for high-performance coatings that can withstand extreme conditions and improve product longevity. As industries continue to innovate and seek more efficient manufacturing processes, the vacuum coating machines market is expected to grow, offering new opportunities for technological advancements and market expansion. The market is characterized by a diverse range of players, from established manufacturers to emerging companies, all striving to meet the evolving needs of their customers. With the increasing focus on sustainability and energy efficiency, vacuum coating technologies are also being developed to reduce environmental impact and enhance resource utilization. Overall, the Global Vacuum Coating Machines Market is poised for significant growth, driven by technological advancements and the increasing demand for high-quality coatings across various industries.

Vacuum Evaporation Coating Machine, Vacuum Sputtering Coating Machine, Others in the Global Vacuum Coating Machines Market:

Vacuum coating machines are essential tools in the manufacturing sector, offering a variety of methods to apply coatings to different substrates. Among these, the Vacuum Evaporation Coating Machine is a prominent technology. This machine operates by heating a coating material until it evaporates in a vacuum chamber, allowing the vapor to condense on the substrate, forming a thin film. This method is widely used for its ability to produce uniform coatings with excellent adhesion and is particularly popular in the electronics and optics industries. The precision and control offered by vacuum evaporation make it ideal for applications requiring high-quality coatings with specific optical or electrical properties. On the other hand, the Vacuum Sputtering Coating Machine employs a different technique. It uses a plasma to bombard a target material, causing atoms to be ejected and deposited onto the substrate. This process is highly versatile and can be used to coat a wide range of materials, including metals, ceramics, and polymers. Sputtering is favored for its ability to produce dense, durable coatings with excellent uniformity, making it suitable for applications in the automotive and aerospace industries. Additionally, the market includes other types of vacuum coating machines, each with its unique advantages and applications. For instance, Chemical Vapor Deposition (CVD) and Physical Vapor Deposition (PVD) are popular methods that offer distinct benefits in terms of coating quality and process efficiency. CVD involves the chemical reaction of gaseous precursors to form a solid film on the substrate, while PVD encompasses a range of techniques, including evaporation and sputtering, to deposit thin films. These technologies are continually evolving, with ongoing research and development efforts aimed at improving coating performance, reducing costs, and expanding the range of materials that can be coated. As industries demand more sophisticated coatings to enhance product performance and meet regulatory requirements, the vacuum coating machines market is expected to witness significant growth. Manufacturers are investing in advanced technologies and expanding their product portfolios to cater to the diverse needs of their customers. The market is also seeing increased collaboration between companies and research institutions to develop innovative solutions that address emerging challenges and opportunities. Overall, the vacuum coating machines market is a dynamic and competitive landscape, driven by technological advancements and the growing demand for high-performance coatings across various industries.

Semiconductor and Electronics, Optics and Glass, Automotive, Tools and Hardware, Others in the Global Vacuum Coating Machines Market:

The Global Vacuum Coating Machines Market finds extensive applications across several key industries, each leveraging the unique benefits of vacuum coating technologies to enhance product performance and quality. In the semiconductor and electronics sector, vacuum coating machines are indispensable for the production of microchips, circuit boards, and other electronic components. These machines enable the deposition of thin films with precise control over thickness and composition, which is critical for ensuring the functionality and reliability of electronic devices. The coatings applied through vacuum processes can improve electrical conductivity, protect against corrosion, and enhance thermal management, making them essential for the advancement of modern electronics. In the optics and glass industry, vacuum coating machines are used to apply anti-reflective, scratch-resistant, and other functional coatings to lenses, mirrors, and display panels. These coatings enhance optical performance by reducing glare, improving light transmission, and increasing durability. The automotive industry also benefits significantly from vacuum coating technologies, which are used to apply decorative and protective coatings to various components, including wheels, trim, and interior parts. These coatings not only enhance the aesthetic appeal of vehicles but also provide resistance to wear, corrosion, and environmental factors. In the tools and hardware sector, vacuum coatings are applied to cutting tools, molds, and other equipment to improve hardness, reduce friction, and extend service life. This results in increased productivity and cost savings for manufacturers. Beyond these industries, vacuum coating machines are also used in a variety of other applications, such as in the production of solar panels, medical devices, and packaging materials. The versatility and efficiency of vacuum coating technologies make them an attractive choice for manufacturers seeking to enhance product performance and meet the demands of increasingly competitive markets. As industries continue to evolve and innovate, the Global Vacuum Coating Machines Market is expected to grow, driven by the need for advanced coatings that offer superior performance and sustainability.

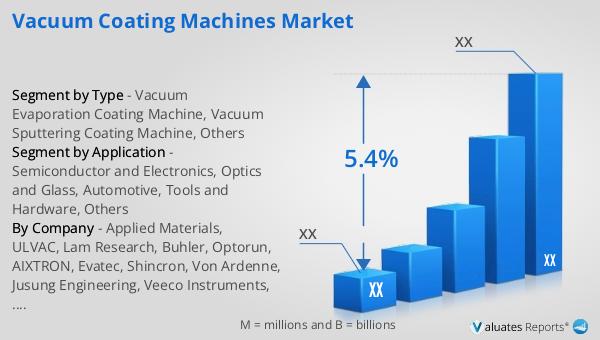

Global Vacuum Coating Machines Market Outlook:

In 2024, the global market size for Vacuum Coating Machines was valued at approximately US$ 4,556 million. This market is projected to grow significantly, reaching an estimated value of around US$ 6,550 million by 2031. This growth is expected to occur at a compound annual growth rate (CAGR) of 5.4% during the forecast period from 2025 to 2031. The market is dominated by a few key players, with Applied Materials, ULVAC, Shincron, Buhler, and Optorun being the top five manufacturers in the industry. Together, these companies hold about 70% of the market share, indicating a highly consolidated market structure. These leading manufacturers are at the forefront of innovation, continuously developing new technologies and expanding their product offerings to meet the evolving needs of their customers. The strong market position of these companies is a testament to their expertise, quality, and commitment to delivering high-performance vacuum coating solutions. As the demand for advanced coatings continues to rise across various industries, these manufacturers are well-positioned to capitalize on the growth opportunities in the market. The competitive landscape is characterized by ongoing research and development efforts, strategic partnerships, and a focus on sustainability and energy efficiency. Overall, the Global Vacuum Coating Machines Market is poised for significant growth, driven by technological advancements and the increasing demand for high-quality coatings across diverse applications.

| Report Metric | Details |

| Report Name | Vacuum Coating Machines Market |

| CAGR | 5.4% |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Applied Materials, ULVAC, Lam Research, Buhler, Optorun, AIXTRON, Evatec, Shincron, Von Ardenne, Jusung Engineering, Veeco Instruments, CVD Equipment Corporation, IHI, BOBST, Hanil Vacuum, Dongguan Huicheng Technology Co,Ltd, Platit, Lung Pien Vacuum, Beijing Power Tech, Hongda Vacuum, Denton Vacuum, Mustang Vacuum Systems, SKY Technology, Guangdong Zhenhua Technology, Satisloh, Impact Coatings, HCVAC, ZHEN HUA, KYZK |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |