What is Global Soldering Robot Market?

The Global Soldering Robot Market refers to the industry focused on the development, production, and distribution of robotic systems designed specifically for soldering tasks. Soldering robots are automated machines that perform soldering operations, which involve joining two or more electronic components together by melting solder around the connection. These robots are increasingly used in various industries due to their precision, efficiency, and ability to work continuously without fatigue. The market for soldering robots is driven by the growing demand for automation in manufacturing processes, particularly in the electronics sector, where precision and reliability are crucial. As technology advances, these robots are becoming more sophisticated, offering features such as multi-axis movement, advanced programming capabilities, and integration with other automated systems. This market is expanding globally, with significant contributions from regions like Asia-Pacific, where manufacturing activities are prominent. The adoption of soldering robots helps companies improve production quality, reduce labor costs, and enhance overall operational efficiency, making them an attractive investment for businesses looking to stay competitive in the fast-paced manufacturing landscape.

6-Axis Robot, 5-Axis Robot, 4-Axis Robot, 3-Axis Robot, 2-Axis Robot in the Global Soldering Robot Market:

In the Global Soldering Robot Market, robots are categorized based on the number of axes they possess, which determines their range of motion and flexibility. A 6-Axis Robot is the most versatile, offering six degrees of freedom, which allows it to move in three-dimensional space with high precision. This type of robot can perform complex soldering tasks, such as reaching around obstacles and working in confined spaces, making it ideal for intricate electronic assemblies. The 5-Axis Robot, while slightly less flexible than its 6-axis counterpart, still provides a significant range of motion, suitable for most soldering applications. It can handle tasks that require a moderate level of complexity and precision, often used in medium-scale manufacturing operations. The 4-Axis Robot is designed for simpler tasks, offering movement in four directions. It is typically used in applications where the soldering path is straightforward and does not require extensive maneuvering. This type of robot is cost-effective and efficient for repetitive tasks in high-volume production environments. The 3-Axis Robot is even more limited in its movement, suitable for basic soldering operations where the components are aligned in a linear fashion. It is often employed in small-scale operations or for tasks that do not require high precision. Lastly, the 2-Axis Robot is the most basic, offering movement in just two directions. It is used for very simple soldering tasks, often in conjunction with other automated systems to complete a larger assembly process. Each type of robot serves a specific purpose within the soldering process, and the choice of robot depends on the complexity of the task, the required precision, and the production volume. As the demand for automation increases, manufacturers are continually developing more advanced robots to meet the diverse needs of the industry.

Consumer Electronics, Appliances Electronics, Automotive Electronics, Others in the Global Soldering Robot Market:

The Global Soldering Robot Market finds extensive usage across various sectors, including Consumer Electronics, Appliances Electronics, Automotive Electronics, and others. In the Consumer Electronics sector, soldering robots are crucial for assembling devices like smartphones, tablets, and laptops. These robots ensure that the tiny components within these gadgets are soldered with precision, enhancing the device's performance and longevity. The high demand for consumer electronics drives the need for efficient and reliable soldering solutions, making robots an indispensable part of the production line. In the Appliances Electronics sector, soldering robots are used to assemble components in household appliances such as refrigerators, washing machines, and microwaves. These robots help manufacturers maintain consistent quality and reduce production time, which is essential in a market driven by consumer demand for durable and efficient appliances. The Automotive Electronics sector also heavily relies on soldering robots, as modern vehicles are equipped with numerous electronic systems, from infotainment units to advanced driver-assistance systems. Soldering robots ensure that these components are assembled accurately, contributing to the vehicle's overall safety and functionality. Additionally, soldering robots are used in other industries, such as telecommunications and aerospace, where precision and reliability are paramount. The versatility and efficiency of soldering robots make them a valuable asset in any industry that requires high-quality electronic assembly. As technology continues to evolve, the applications of soldering robots are expected to expand, further driving the growth of the Global Soldering Robot Market.

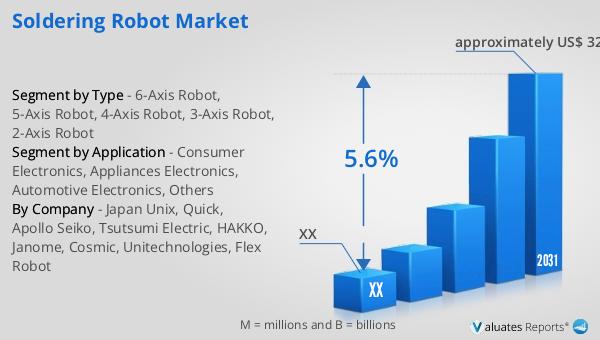

Global Soldering Robot Market Outlook:

In 2024, the global market size for Soldering Robots was valued at approximately US$ 224 million. It is projected to grow significantly, reaching around US$ 326 million by 2031, with a compound annual growth rate (CAGR) of 5.6% during the forecast period from 2025 to 2031. Japan holds the largest share of the Soldering Robot market, accounting for about 46% of the total market share. Following closely is China, which represents approximately 40% of the market share. The top five companies in this sector collectively occupy about 47% of the market share. This data highlights the dominance of the Asian region in the Soldering Robot market, driven by the robust manufacturing industries in these countries. The growth in this market is attributed to the increasing demand for automation in manufacturing processes, particularly in the electronics sector. As companies strive to enhance production efficiency and reduce labor costs, the adoption of soldering robots is expected to rise. The competitive landscape of the market is characterized by the presence of key players who are continually innovating to offer advanced solutions that meet the evolving needs of the industry. This dynamic market environment presents opportunities for both established companies and new entrants to capitalize on the growing demand for soldering robots.

| Report Metric | Details |

| Report Name | Soldering Robot Market |

| Forecasted market size in 2031 | approximately US$ 326 million |

| CAGR | 5.6% |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Japan Unix, Quick, Apollo Seiko, Tsutsumi Electric, HAKKO, Janome, Cosmic, Unitechnologies, Flex Robot |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |