What is Global Flexible Packaging Laminating Adhesives Market?

The Global Flexible Packaging Laminating Adhesives Market is a dynamic and essential segment of the packaging industry, focusing on the production and application of adhesives used in flexible packaging solutions. These adhesives play a crucial role in bonding different layers of materials, such as plastic films, foils, and papers, to create packaging that is not only durable but also versatile and efficient. Flexible packaging is widely used across various industries due to its lightweight nature, cost-effectiveness, and ability to preserve the freshness and quality of products. The market for these laminating adhesives is driven by the increasing demand for packaged goods, the need for sustainable and eco-friendly packaging solutions, and advancements in adhesive technologies. As consumer preferences shift towards convenience and sustainability, manufacturers are continually innovating to develop adhesives that meet these demands while ensuring high performance and safety standards. The market is characterized by a diverse range of adhesive types, each offering unique properties and benefits, catering to the specific needs of different applications and industries.

Solvent Based Adhesives, Solvent-free Adhesives, Water Based Adhesives in the Global Flexible Packaging Laminating Adhesives Market:

Solvent-based adhesives are a prominent category within the Global Flexible Packaging Laminating Adhesives Market, known for their strong bonding capabilities and versatility. These adhesives are composed of polymers dissolved in organic solvents, which evaporate upon application, leaving a solid adhesive film that bonds the packaging layers together. Solvent-based adhesives are favored for their excellent adhesion to a wide range of substrates, including plastics, metals, and papers, making them suitable for various packaging applications. They offer high initial tack and fast setting times, which are crucial for high-speed production lines. However, the use of organic solvents raises environmental and health concerns due to volatile organic compound (VOC) emissions, prompting manufacturers to seek more sustainable alternatives. Despite these challenges, solvent-based adhesives remain popular in applications where strong adhesion and resistance to harsh conditions are paramount. Solvent-free adhesives, on the other hand, are gaining traction in the market due to their environmentally friendly profile. These adhesives do not contain organic solvents, eliminating VOC emissions and reducing the environmental impact of the packaging process. Solvent-free adhesives are typically based on polyurethane or acrylic chemistries and are applied as 100% solid formulations. They offer excellent adhesion to a variety of substrates and are suitable for food packaging applications due to their low odor and non-toxic nature. The absence of solvents also reduces the risk of contamination, making them ideal for sensitive applications such as medical and pharmaceutical packaging. While solvent-free adhesives may have longer curing times compared to their solvent-based counterparts, advancements in technology are addressing these limitations, making them increasingly competitive in the market. Water-based adhesives represent another significant segment of the Global Flexible Packaging Laminating Adhesives Market. These adhesives use water as the primary solvent, making them an eco-friendly alternative to solvent-based systems. Water-based adhesives are typically formulated with natural or synthetic polymers dispersed in water, which evaporates upon application, leaving a strong adhesive bond. They are known for their low VOC emissions, safety, and ease of use, making them suitable for a wide range of applications, including food and beverage packaging, personal care products, and industrial goods. Water-based adhesives offer good adhesion to various substrates and are compatible with high-speed production processes. However, their performance can be affected by factors such as humidity and temperature, which may limit their use in certain environments. Despite these challenges, the demand for water-based adhesives is growing as manufacturers and consumers prioritize sustainability and safety in packaging solutions. In summary, the Global Flexible Packaging Laminating Adhesives Market is characterized by a diverse range of adhesive types, each offering unique properties and benefits. Solvent-based adhesives are valued for their strong bonding capabilities and versatility, but face challenges related to environmental and health concerns. Solvent-free adhesives are gaining popularity due to their eco-friendly profile and suitability for sensitive applications, while water-based adhesives offer a sustainable alternative with low VOC emissions and ease of use. As the market continues to evolve, manufacturers are focusing on developing innovative adhesive solutions that meet the demands of sustainability, performance, and safety, driving growth and innovation in the flexible packaging industry.

Food Packaging, Medical Packaging, Industrial Packaging, Personal Care & Cosmetics Packaging, Others in the Global Flexible Packaging Laminating Adhesives Market:

The usage of Global Flexible Packaging Laminating Adhesives Market spans across various sectors, each with specific requirements and challenges. In the food packaging industry, these adhesives play a vital role in ensuring the safety, freshness, and shelf life of food products. Flexible packaging solutions, such as pouches, bags, and wraps, rely on laminating adhesives to bond multiple layers of materials, creating a barrier against moisture, oxygen, and contaminants. This is crucial for preserving the quality and flavor of food items, especially perishable goods. Adhesives used in food packaging must comply with stringent safety and regulatory standards to ensure they do not compromise the integrity of the food products. In the medical packaging sector, flexible packaging laminating adhesives are used to create sterile and secure packaging solutions for medical devices, pharmaceuticals, and other healthcare products. These adhesives must provide strong bonds that withstand sterilization processes and protect the contents from contamination and damage. The adhesives used in medical packaging are often solvent-free or water-based to minimize the risk of chemical contamination and ensure patient safety. The demand for reliable and safe medical packaging solutions is driving innovation in adhesive technologies, with manufacturers focusing on developing adhesives that meet the stringent requirements of the healthcare industry. Industrial packaging is another significant area where flexible packaging laminating adhesives are utilized. Industrial goods, such as chemicals, automotive parts, and machinery components, require robust packaging solutions that can withstand harsh conditions during transportation and storage. Laminating adhesives provide the necessary strength and durability to protect these products from damage, moisture, and environmental factors. Solvent-based adhesives are often preferred in industrial packaging due to their strong bonding capabilities and resistance to extreme conditions. However, as sustainability becomes a priority, there is a growing interest in solvent-free and water-based adhesives that offer similar performance with reduced environmental impact. In the personal care and cosmetics packaging industry, flexible packaging laminating adhesives are used to create attractive and functional packaging solutions for products such as shampoos, lotions, and makeup. These adhesives must provide strong bonds that maintain the integrity of the packaging while also allowing for creative designs and finishes. The aesthetics of packaging are crucial in this sector, as they influence consumer purchasing decisions. Adhesives used in personal care and cosmetics packaging must be compatible with various materials and finishes, such as glossy, matte, or metallic, to achieve the desired look and feel. Additionally, they must comply with safety regulations to ensure they do not react with the product contents. Beyond these primary sectors, flexible packaging laminating adhesives are also used in other applications, such as electronics packaging, household goods, and agricultural products. Each of these areas presents unique challenges and requirements, driving the need for specialized adhesive solutions. As the demand for flexible packaging continues to grow, manufacturers are investing in research and development to create innovative adhesives that meet the diverse needs of different industries. The focus is on developing adhesives that offer high performance, safety, and sustainability, ensuring they contribute to the overall efficiency and effectiveness of packaging solutions.

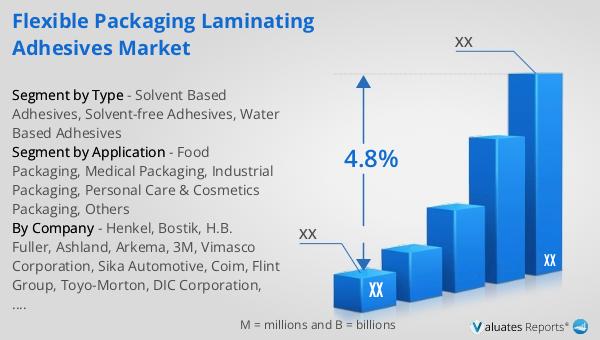

Global Flexible Packaging Laminating Adhesives Market Outlook:

In 2024, the global market size for Flexible Packaging Laminating Adhesives was valued at approximately US$ 5,322 million. It is anticipated to expand significantly, reaching around US$ 7,459 million by 2031. This growth trajectory reflects a compound annual growth rate (CAGR) of 4.8% during the forecast period from 2025 to 2031. Over the next decade, the market is expected to grow at an approximate CAGR of 5%. This expansion is largely driven by factors such as rapid urbanization, evolving consumer lifestyles, and an increasing preference for convenience packaging. As urban areas continue to expand, the demand for packaged goods rises, necessitating efficient and reliable packaging solutions. Additionally, changing consumer lifestyles, characterized by a preference for on-the-go and easy-to-use products, are fueling the demand for flexible packaging. The rising awareness of environmental sustainability is also influencing the market, with consumers and manufacturers alike seeking eco-friendly packaging options. These trends are prompting manufacturers to innovate and develop advanced adhesive solutions that cater to the evolving needs of the market. As a result, the Global Flexible Packaging Laminating Adhesives Market is poised for significant growth, driven by the convergence of these dynamic factors.

| Report Metric | Details |

| Report Name | Flexible Packaging Laminating Adhesives Market |

| CAGR | 4.8% |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Henkel, Bostik, H.B. Fuller, Ashland, Arkema, 3M, Vimasco Corporation, Sika Automotive, Coim, Flint Group, Toyo-Morton, DIC Corporation, Huber Group, Comens Material, China Neweast, Jiangsu Lihe, Morchem SA, Shanghai Kangda, Brilliant Polymers, Sungdo, UFlex, Rockpaint, Mitsui Chemicals, Sapicci, Wanhua |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |