What is Global Pharmaceutical Grade Glycine Market?

The Global Pharmaceutical Grade Glycine Market refers to the segment of the glycine industry that focuses on producing glycine with high purity levels suitable for pharmaceutical applications. Glycine, a non-essential amino acid, is utilized in various pharmaceutical formulations due to its role in protein synthesis and its function as a neurotransmitter. This market is driven by the increasing demand for high-quality glycine in the pharmaceutical sector, where it is used in the production of drugs, supplements, and other health-related products. The pharmaceutical grade glycine is characterized by its high purity, typically exceeding 98% or 99%, to ensure safety and efficacy in medical applications. The market is influenced by factors such as advancements in pharmaceutical manufacturing, regulatory standards, and the growing emphasis on health and wellness. As pharmaceutical companies strive to meet stringent quality requirements, the demand for pharmaceutical grade glycine continues to rise, contributing to the market's expansion. This market is also impacted by global health trends, technological innovations, and the need for effective therapeutic solutions, making it a critical component of the broader pharmaceutical industry.

>98%, >99% in the Global Pharmaceutical Grade Glycine Market:

In the Global Pharmaceutical Grade Glycine Market, purity levels such as >98% and >99% play a crucial role in determining the quality and applicability of glycine in pharmaceutical products. Glycine with a purity level of >98% is often used in applications where high purity is essential but not the absolute highest available. This level of purity ensures that the glycine is free from most impurities, making it suitable for a wide range of pharmaceutical formulations, including oral and injectable drugs. The >98% purity glycine is typically used in the production of amino acid supplements, where it contributes to protein synthesis and overall health. On the other hand, glycine with a purity level of >99% represents the highest standard of purity available in the market. This ultra-pure form of glycine is critical for applications that require the utmost precision and safety, such as in the formulation of critical care medications and advanced therapeutic solutions. The >99% purity glycine is often used in the production of intravenous solutions, where even the slightest impurity could compromise patient safety. The demand for >99% purity glycine is driven by the increasing complexity of pharmaceutical formulations and the need for highly reliable ingredients. Both >98% and >99% purity levels are subject to stringent quality control measures to ensure compliance with international pharmaceutical standards. The production of these high-purity glycine variants involves advanced manufacturing processes and rigorous testing to eliminate contaminants and ensure consistency. As the pharmaceutical industry continues to evolve, the demand for high-purity glycine is expected to grow, driven by the need for safe and effective pharmaceutical products. The choice between >98% and >99% purity glycine depends on the specific requirements of the pharmaceutical application, with each level offering distinct advantages in terms of purity, safety, and efficacy. The Global Pharmaceutical Grade Glycine Market is characterized by a focus on quality and innovation, with manufacturers continually striving to meet the evolving needs of the pharmaceutical industry. As a result, the market for high-purity glycine is poised for growth, supported by advancements in manufacturing technology and increasing awareness of the importance of purity in pharmaceutical applications.

Hospital, Clinic, Other in the Global Pharmaceutical Grade Glycine Market:

The Global Pharmaceutical Grade Glycine Market finds its usage in various healthcare settings, including hospitals, clinics, and other medical facilities. In hospitals, pharmaceutical grade glycine is used in the formulation of intravenous solutions and other critical care medications. Its high purity levels ensure that these formulations are safe for use in patients with severe health conditions, where even minor impurities could lead to adverse effects. Glycine's role as a neurotransmitter also makes it valuable in the development of medications for neurological disorders, which are often administered in hospital settings. In clinics, pharmaceutical grade glycine is used in the preparation of oral medications and dietary supplements. Clinics often focus on preventive care and wellness, and glycine's role in protein synthesis and overall health makes it a popular ingredient in supplements aimed at improving patient outcomes. The high purity of pharmaceutical grade glycine ensures that these supplements are safe and effective, providing patients with the necessary nutrients to support their health. In other medical facilities, such as research laboratories and specialty care centers, pharmaceutical grade glycine is used in the development of new drugs and therapeutic solutions. Researchers rely on high-purity glycine to ensure the accuracy and reliability of their experiments, as impurities could skew results and compromise the validity of their findings. The versatility of pharmaceutical grade glycine makes it a valuable component in a wide range of medical applications, from drug development to patient care. Its high purity levels ensure that it meets the stringent quality standards required in the healthcare industry, making it a trusted ingredient in the formulation of safe and effective pharmaceutical products. As the demand for high-quality healthcare solutions continues to grow, the usage of pharmaceutical grade glycine in hospitals, clinics, and other medical facilities is expected to increase, driven by the need for reliable and effective therapeutic options.

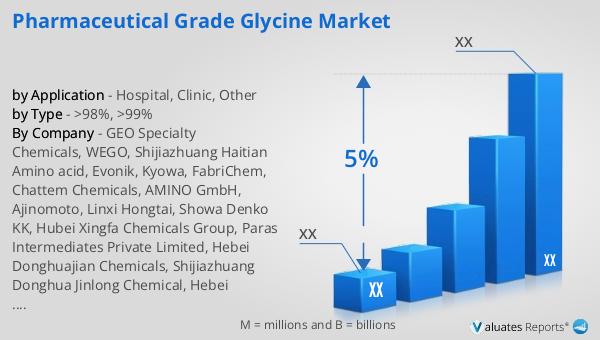

Global Pharmaceutical Grade Glycine Market Outlook:

The global pharmaceutical market was valued at approximately 1,475 billion USD in 2022, with an anticipated compound annual growth rate (CAGR) of 5% over the next six years. This growth trajectory highlights the robust expansion of the pharmaceutical sector, driven by factors such as increasing healthcare needs, technological advancements, and the rising prevalence of chronic diseases. In comparison, the chemical drug market has also shown significant growth, with its value increasing from 1,005 billion USD in 2018 to 1,094 billion USD in 2022. This growth in the chemical drug market underscores the ongoing demand for chemical-based therapeutic solutions, which continue to play a vital role in modern medicine. The expansion of both the pharmaceutical and chemical drug markets reflects the broader trends in the healthcare industry, where innovation and the development of new treatments are paramount. As these markets continue to grow, they present numerous opportunities for stakeholders, including manufacturers, researchers, and healthcare providers, to contribute to the advancement of medical science and improve patient outcomes. The sustained growth of these markets is indicative of the dynamic nature of the healthcare industry, where continuous improvement and adaptation are essential to meet the evolving needs of patients worldwide.

| Report Metric | Details |

| Report Name | Pharmaceutical Grade Glycine Market |

| CAGR | 5% |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | GEO Specialty Chemicals, WEGO, Shijiazhuang Haitian Amino acid, Evonik, Kyowa, FabriChem, Chattem Chemicals, AMINO GmbH, Ajinomoto, Linxi Hongtai, Showa Denko KK, Hubei Xingfa Chemicals Group, Paras Intermediates Private Limited, Hebei Donghuajian Chemicals, Shijiazhuang Donghua Jinlong Chemical, Hebei Donghua Jiheng Chemical |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |