What is Global Hydroxyl Functional Acrylic Monomers Market?

The Global Hydroxyl Functional Acrylic Monomers Market is a specialized segment within the broader chemical industry, focusing on the production and distribution of acrylic monomers that possess hydroxyl functional groups. These monomers are essential building blocks in the creation of various polymers and copolymers, which are used in a wide range of applications due to their unique properties. The market is driven by the demand for high-performance materials that offer enhanced durability, flexibility, and resistance to environmental factors. Hydroxyl functional acrylic monomers are particularly valued for their ability to improve the adhesion, gloss, and weatherability of coatings, making them indispensable in industries such as automotive, construction, and electronics. Additionally, these monomers play a crucial role in the formulation of adhesives, sealants, and textile finishes, where their chemical properties contribute to improved performance and longevity. The market is characterized by ongoing research and development efforts aimed at enhancing the functionality and sustainability of these monomers, as well as expanding their application scope. As industries continue to seek innovative solutions to meet evolving consumer demands and regulatory requirements, the Global Hydroxyl Functional Acrylic Monomers Market is poised for steady growth and diversification.

Hydroxyethyl Acrylate (HEA), Hydroxypropyl Acrylate (HPA), Hydroxyethyl Mmethacrylate (HEMA), Hydroxypropyl Methacrylate (HPMA) in the Global Hydroxyl Functional Acrylic Monomers Market:

Hydroxyethyl Acrylate (HEA), Hydroxypropyl Acrylate (HPA), Hydroxyethyl Methacrylate (HEMA), and Hydroxypropyl Methacrylate (HPMA) are key components of the Global Hydroxyl Functional Acrylic Monomers Market, each offering distinct properties that cater to various industrial needs. HEA is known for its excellent adhesion properties and is widely used in the production of coatings and adhesives. Its ability to enhance the flexibility and durability of products makes it a preferred choice in the automotive and construction industries. HPA, on the other hand, is valued for its superior water resistance and is often utilized in applications where moisture exposure is a concern. This makes it ideal for use in sealants and protective coatings. HEMA is a versatile monomer that finds applications in the medical field, particularly in the production of contact lenses and dental materials, due to its biocompatibility and hydrophilic nature. Its ability to form clear, hard films also makes it suitable for use in coatings and adhesives. HPMA shares similar properties with HEMA but offers enhanced thermal stability, making it suitable for high-temperature applications. It is commonly used in the production of heat-resistant coatings and adhesives. The unique properties of these monomers make them indispensable in the formulation of high-performance materials that meet the stringent requirements of modern industries. As the demand for advanced materials continues to grow, the role of HEA, HPA, HEMA, and HPMA in the Global Hydroxyl Functional Acrylic Monomers Market is expected to expand, driven by ongoing innovations and the development of new applications.

Coatings, Textile, Adhesives, Polymer Materials, Others in the Global Hydroxyl Functional Acrylic Monomers Market:

The Global Hydroxyl Functional Acrylic Monomers Market plays a pivotal role in various industries, with its applications spanning across coatings, textiles, adhesives, polymer materials, and more. In the coatings industry, these monomers are used to enhance the performance of paints and varnishes, providing improved adhesion, gloss, and resistance to environmental factors such as UV radiation and moisture. This makes them ideal for use in automotive and architectural coatings, where durability and aesthetic appeal are paramount. In the textile industry, hydroxyl functional acrylic monomers are used to improve the softness, flexibility, and durability of fabrics. They are often employed in the production of textile finishes that provide water and stain resistance, as well as enhanced color retention. In the adhesives sector, these monomers contribute to the development of high-performance adhesives that offer superior bonding strength and flexibility. They are used in a wide range of applications, from construction and automotive to electronics and packaging. In the realm of polymer materials, hydroxyl functional acrylic monomers are used to create polymers with specific properties, such as increased toughness, elasticity, and thermal stability. These polymers are used in a variety of applications, including the production of films, foams, and molded parts. Beyond these primary applications, hydroxyl functional acrylic monomers are also used in other industries, such as healthcare and personal care, where their unique properties contribute to the development of innovative products. As industries continue to seek advanced materials that offer enhanced performance and sustainability, the Global Hydroxyl Functional Acrylic Monomers Market is poised to play an increasingly important role in meeting these demands.

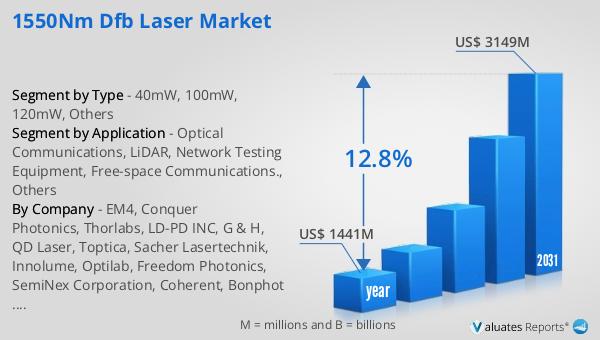

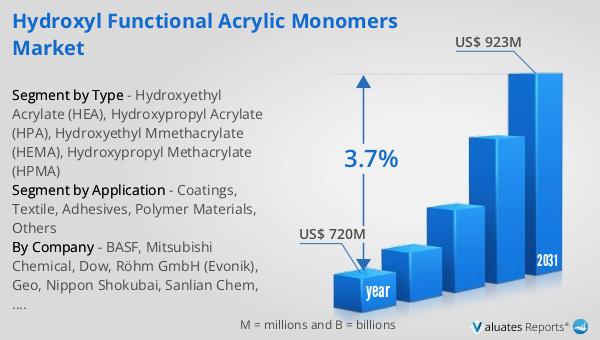

Global Hydroxyl Functional Acrylic Monomers Market Outlook:

The global market for Hydroxyl Functional Acrylic Monomers was valued at US$ 720 million in 2024 and is anticipated to grow to a revised size of US$ 923 million by 2031, reflecting a compound annual growth rate (CAGR) of 3.7% over the forecast period. This growth trajectory underscores the increasing demand for these monomers across various industries, driven by their unique properties and versatility. The market's expansion is fueled by the rising need for high-performance materials that can withstand harsh environmental conditions and meet stringent regulatory standards. As industries such as automotive, construction, and electronics continue to evolve, the demand for advanced coatings, adhesives, and polymer materials is expected to rise, further propelling the market's growth. Additionally, ongoing research and development efforts aimed at enhancing the functionality and sustainability of hydroxyl functional acrylic monomers are likely to open new avenues for market expansion. The market's growth is also supported by the increasing focus on sustainability and the development of eco-friendly products, as consumers and industries alike seek to reduce their environmental footprint. As a result, the Global Hydroxyl Functional Acrylic Monomers Market is poised for steady growth, driven by innovation and the development of new applications that cater to the evolving needs of modern industries.

| Report Metric | Details |

| Report Name | Hydroxyl Functional Acrylic Monomers Market |

| Accounted market size in year | US$ 720 million |

| Forecasted market size in 2031 | US$ 923 million |

| CAGR | 3.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | BASF, Mitsubishi Chemical, Dow, Röhm GmbH (Evonik), Geo, Nippon Shokubai, Sanlian Chem, Anhui Renxin, Shandong Xinglu Biological Technology, Hickory, Wanhua Chemical, Fangda Chem, Hechuang Chem, Heze Changshengyuan, Guangdong Redwall New Materials, Derui Polymer Materials |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |