What is Global Hybrid Memory Cube (HMC) and High-bandwidth Memory (HBM) Market?

The Global Hybrid Memory Cube (HMC) and High-bandwidth Memory (HBM) market represents a significant advancement in memory technology, offering enhanced performance and efficiency for various computing applications. HMC and HBM are types of high-speed memory architectures designed to overcome the limitations of traditional memory systems. HMC utilizes a 3D architecture, stacking multiple memory dies vertically, which allows for faster data transfer rates and reduced power consumption. This design is particularly beneficial for applications requiring high bandwidth and low latency. On the other hand, HBM is a high-performance RAM interface for 3D-stacked DRAM (dynamic random-access memory) used in conjunction with high-performance graphics accelerators and network devices. It provides a wide interface and high bandwidth, making it ideal for tasks that demand rapid data processing. Both HMC and HBM are crucial in addressing the growing need for efficient data handling in modern computing environments, supporting advancements in areas such as artificial intelligence, machine learning, and big data analytics. As the demand for faster and more efficient memory solutions continues to rise, the market for HMC and HBM is expected to expand, driven by their ability to enhance the performance of various computing systems.

Graphics Processing Unit (GPU), Central Processing Unit (CPU), Accelerated Processing Unit (APU), Field-programmable Gate Array (FPGA), Application-specific Integrated Circuit (ASIC) in the Global Hybrid Memory Cube (HMC) and High-bandwidth Memory (HBM) Market:

In the realm of computing, various processing units play pivotal roles, each with unique characteristics and applications, especially when integrated with advanced memory technologies like Global Hybrid Memory Cube (HMC) and High-bandwidth Memory (HBM). The Graphics Processing Unit (GPU) is a specialized processor designed to accelerate graphics rendering. With the integration of HBM, GPUs can handle massive data sets and complex computations more efficiently, making them indispensable in gaming, professional visualization, and AI applications. The Central Processing Unit (CPU), often considered the brain of the computer, executes instructions from programs. When paired with HMC, CPUs benefit from increased data throughput and reduced latency, enhancing overall system performance, particularly in data-intensive tasks. The Accelerated Processing Unit (APU) combines the capabilities of a CPU and a GPU on a single chip, offering a balanced performance for both general-purpose and graphics-intensive applications. The use of HBM in APUs can significantly boost their efficiency, making them suitable for compact devices that require robust processing power. Field-programmable Gate Arrays (FPGAs) are integrated circuits that can be configured by the customer or designer after manufacturing. They are highly versatile and can be optimized for specific tasks. When equipped with HMC, FPGAs can achieve higher bandwidth and lower power consumption, which is crucial for applications in telecommunications, automotive, and industrial automation. Application-specific Integrated Circuits (ASICs) are custom-designed for a particular application or product. The integration of HBM in ASICs allows for tailored solutions that require high-speed data processing, such as cryptocurrency mining and advanced scientific computations. Each of these processing units, when combined with HMC and HBM, can significantly enhance their performance, addressing the growing demands of modern computing tasks. The synergy between these advanced memory technologies and processing units is driving innovation across various industries, enabling more efficient and powerful computing solutions. As technology continues to evolve, the integration of HMC and HBM with GPUs, CPUs, APUs, FPGAs, and ASICs will play a crucial role in shaping the future of computing, offering unprecedented levels of performance and efficiency.

Graphics, High-performance Computing, Networking, Data Centers, Others in the Global Hybrid Memory Cube (HMC) and High-bandwidth Memory (HBM) Market:

The application of Global Hybrid Memory Cube (HMC) and High-bandwidth Memory (HBM) in various sectors highlights their versatility and importance in modern technology. In graphics, HBM is particularly beneficial as it provides the necessary bandwidth to handle high-resolution textures and complex visual effects, making it a staple in the development of cutting-edge graphics cards used in gaming and professional visualization. The ability to process large amounts of data quickly and efficiently is crucial in rendering lifelike graphics and ensuring smooth gameplay experiences. In high-performance computing (HPC), both HMC and HBM are invaluable. They enable supercomputers to perform complex simulations and calculations at unprecedented speeds, supporting scientific research, weather forecasting, and financial modeling. The high bandwidth and low latency of these memory technologies allow for faster data processing, which is essential in solving complex computational problems. Networking is another area where HMC and HBM make a significant impact. As data traffic continues to grow, the need for efficient data handling becomes paramount. These memory technologies support high-speed data transfer and processing, which are critical in maintaining robust and reliable network infrastructures. In data centers, the integration of HMC and HBM helps in managing the massive influx of data generated by cloud computing and big data analytics. They provide the necessary speed and efficiency to handle large-scale data processing tasks, ensuring that data centers can operate smoothly and effectively. Other applications include artificial intelligence and machine learning, where the rapid processing capabilities of HMC and HBM are leveraged to train complex models and algorithms. The ability to quickly access and process large datasets is crucial in developing intelligent systems that can learn and adapt. Overall, the use of HMC and HBM across these areas underscores their importance in driving technological advancements and meeting the demands of modern computing environments. As industries continue to evolve, the role of these memory technologies will become increasingly significant, supporting innovation and efficiency in various applications.

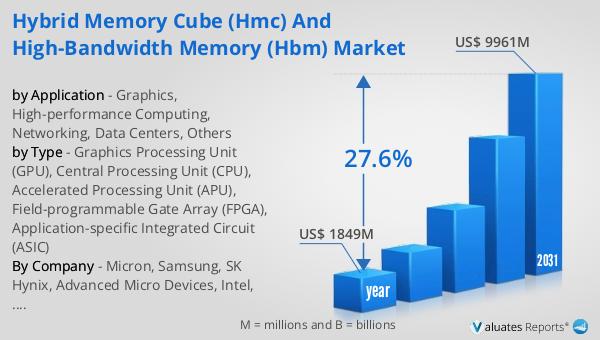

Global Hybrid Memory Cube (HMC) and High-bandwidth Memory (HBM) Market Outlook:

The outlook for the Global Hybrid Memory Cube (HMC) and High-bandwidth Memory (HBM) market is promising, with significant growth anticipated in the coming years. In 2024, the market was valued at approximately $1,849 million, reflecting the increasing demand for advanced memory solutions in various industries. By 2031, this market is expected to expand substantially, reaching an estimated value of $9,961 million. This growth trajectory represents a compound annual growth rate (CAGR) of 27.6% over the forecast period. This impressive growth can be attributed to the rising need for high-speed, efficient memory technologies that can support the ever-increasing data processing requirements of modern computing applications. As industries such as artificial intelligence, high-performance computing, and data centers continue to evolve, the demand for HMC and HBM is expected to rise, driving further market expansion. The ability of these memory technologies to enhance performance, reduce power consumption, and support complex computational tasks makes them an attractive choice for a wide range of applications. As a result, the Global HMC and HBM market is poised for significant growth, offering numerous opportunities for innovation and development in the field of memory technology.

| Report Metric | Details |

| Report Name | Hybrid Memory Cube (HMC) and High-bandwidth Memory (HBM) Market |

| Accounted market size in year | US$ 1849 million |

| Forecasted market size in 2031 | US$ 9961 million |

| CAGR | 27.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Micron, Samsung, SK Hynix, Advanced Micro Devices, Intel, Xilinx, Fujitsu, Nvidia, IBM, Open-Silicon, Arira, Cadence, Marvell, Cray, Rambus, Arm |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |