What is Global Float Level Sensors Market?

The Global Float Level Sensors Market is a dynamic and essential segment within the broader sensor industry, focusing on devices that measure the level of liquid within a container. These sensors are crucial in various industries, including automotive, oil and gas, water treatment, and food and beverage, where precise liquid level measurement is vital for operational efficiency and safety. Float level sensors operate by using a float, which rises and falls with the liquid level, to provide accurate readings. The market is driven by the increasing demand for automation and control systems across industries, as well as the need for efficient and reliable liquid level measurement solutions. Technological advancements have led to the development of more sophisticated and accurate sensors, further propelling market growth. Additionally, the push for energy efficiency and stringent environmental regulations are encouraging industries to adopt advanced sensor technologies. As industries continue to evolve and prioritize efficiency and safety, the demand for float level sensors is expected to grow, making this market a critical component of industrial automation and control systems worldwide.

Magnetic Float Level Sensors, Mechanical Float Level Sensors, Others in the Global Float Level Sensors Market:

Magnetic float level sensors are a popular type of float level sensor used in various applications due to their reliability and precision. These sensors operate by using a magnetic float that moves up and down with the liquid level. The movement of the float is detected by a magnetic reed switch or a Hall effect sensor, which then sends a signal to indicate the liquid level. Magnetic float level sensors are known for their durability and ability to operate in harsh environments, making them ideal for industries such as oil and gas, chemical processing, and water treatment. They are also relatively easy to install and maintain, which adds to their appeal. Mechanical float level sensors, on the other hand, are simpler in design and operation. They typically consist of a float attached to a mechanical arm or rod, which moves with the liquid level. This movement is then translated into a mechanical or electrical signal to indicate the level. Mechanical float level sensors are often used in applications where cost is a significant consideration, as they are generally less expensive than their magnetic counterparts. However, they may not be as durable or accurate in extreme conditions. Other types of float level sensors include optical and ultrasonic sensors, which use light or sound waves to detect the liquid level. These sensors are often used in applications where contact with the liquid is not desirable, such as in the food and beverage industry or in corrosive environments. Optical sensors use a light beam to detect the presence of liquid, while ultrasonic sensors use sound waves to measure the distance to the liquid surface. Both types offer high accuracy and can be used in a wide range of applications. The choice of float level sensor depends on various factors, including the type of liquid being measured, the environmental conditions, and the required level of accuracy. Each type of sensor has its advantages and limitations, and selecting the right one is crucial for ensuring accurate and reliable liquid level measurement.

Petroleum Industry, Chemical Industry, Food Industry, Others in the Global Float Level Sensors Market:

The Global Float Level Sensors Market finds extensive usage across several key industries, each with its unique requirements and challenges. In the petroleum industry, float level sensors are indispensable for monitoring the levels of crude oil, refined products, and other liquids in storage tanks and pipelines. Accurate level measurement is crucial for preventing overflows, leaks, and ensuring the efficient operation of refineries and distribution networks. The harsh and often hazardous environments in the petroleum industry necessitate the use of robust and reliable sensors, such as magnetic float level sensors, which can withstand extreme temperatures and pressures. In the chemical industry, float level sensors play a vital role in maintaining the precise levels of various chemicals in storage and processing tanks. The accurate measurement of liquid levels is essential for ensuring the safety and efficiency of chemical processes, as well as for preventing spills and contamination. The corrosive nature of many chemicals requires the use of sensors made from materials that can resist corrosion and withstand harsh conditions. In the food industry, float level sensors are used to monitor the levels of liquids such as milk, juices, and other beverages in processing and storage tanks. The sensors must be made from food-grade materials to ensure compliance with hygiene and safety standards. Additionally, the sensors need to provide accurate and reliable measurements to maintain product quality and consistency. Other industries that utilize float level sensors include water treatment, pharmaceuticals, and manufacturing. In water treatment plants, float level sensors are used to monitor the levels of water and chemicals in various stages of the treatment process. Accurate level measurement is crucial for ensuring the efficient operation of the plant and for meeting regulatory standards. In the pharmaceutical industry, float level sensors are used to monitor the levels of liquids in production and storage tanks, ensuring the accuracy and consistency of pharmaceutical products. The manufacturing industry also relies on float level sensors for monitoring the levels of various liquids used in production processes, such as lubricants, coolants, and cleaning agents. The versatility and reliability of float level sensors make them an essential component in a wide range of industrial applications, contributing to improved efficiency, safety, and product quality.

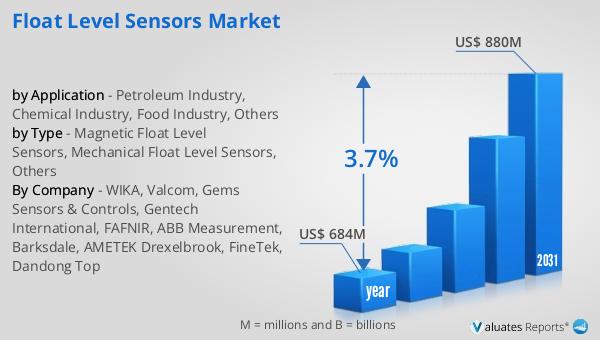

Global Float Level Sensors Market Outlook:

The global market for float level sensors was valued at approximately $684 million in 2024, and it is anticipated to grow to a revised size of around $880 million by 2031. This growth represents a compound annual growth rate (CAGR) of 3.7% over the forecast period. The steady increase in market size reflects the rising demand for accurate and reliable liquid level measurement solutions across various industries. As industries continue to prioritize automation and efficiency, the adoption of advanced sensor technologies is expected to drive market growth. The increasing focus on energy efficiency and environmental sustainability is also contributing to the demand for float level sensors, as they play a crucial role in optimizing industrial processes and reducing waste. Additionally, technological advancements in sensor design and materials are enhancing the performance and durability of float level sensors, making them more attractive to end-users. The market's growth is further supported by the expanding applications of float level sensors in emerging industries and regions, where industrialization and infrastructure development are driving the need for efficient and reliable liquid level measurement solutions. Overall, the global float level sensors market is poised for steady growth, driven by the increasing demand for automation, efficiency, and sustainability across various industries.

| Report Metric | Details |

| Report Name | Float Level Sensors Market |

| Accounted market size in year | US$ 684 million |

| Forecasted market size in 2031 | US$ 880 million |

| CAGR | 3.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | WIKA, Valcom, Gems Sensors & Controls, Gentech International, FAFNIR, ABB Measurement, Barksdale, AMETEK Drexelbrook, FineTek, Dandong Top |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |