What is Global Pharma Grade Calcium Sulphate Market?

The Global Pharma Grade Calcium Sulphate Market is a specialized segment within the broader pharmaceutical industry, focusing on the production and distribution of calcium sulphate that meets stringent pharmaceutical standards. This compound, known for its purity and consistency, is essential in various pharmaceutical applications. Calcium sulphate is primarily used as an excipient, a substance formulated alongside the active ingredient of a medication, to aid in the manufacturing process and enhance the stability and delivery of the drug. The demand for pharma grade calcium sulphate is driven by its role in ensuring the quality and efficacy of pharmaceutical products. It is particularly valued for its ability to act as a filler and binder in tablets and capsules, providing the necessary bulk and cohesion to form solid dosage forms. As the pharmaceutical industry continues to grow, the need for high-quality excipients like calcium sulphate is expected to rise, making this market a critical component of the global healthcare landscape. The market's growth is also influenced by advancements in drug formulation technologies and the increasing emphasis on producing safe and effective medications.

Hydrated Type, Anhydrous Type in the Global Pharma Grade Calcium Sulphate Market:

In the Global Pharma Grade Calcium Sulphate Market, two primary types of calcium sulphate are utilized: hydrated and anhydrous. The hydrated type, also known as calcium sulphate dihydrate, contains water molecules within its crystal structure. This form is commonly used in pharmaceutical applications due to its stability and ease of handling. It is often employed as a filler and binder in tablet formulations, where its ability to absorb moisture can be beneficial in maintaining the integrity of the tablet. The hydrated form is also used in the production of capsules, where it helps to ensure uniformity and consistency in the final product. On the other hand, the anhydrous type of calcium sulphate does not contain water molecules, making it a more concentrated form of the compound. This type is particularly useful in applications where moisture sensitivity is a concern, as it does not contribute additional water to the formulation. Anhydrous calcium sulphate is often used in the production of effervescent tablets, where its lack of moisture can help prevent premature reactions between the active ingredients and other excipients. Both types of calcium sulphate play crucial roles in the pharmaceutical industry, offering unique properties that can be leveraged to optimize drug formulations. The choice between hydrated and anhydrous calcium sulphate depends on the specific requirements of the pharmaceutical product being developed, including factors such as moisture sensitivity, stability, and the desired release profile of the active ingredient. As the demand for innovative drug delivery systems continues to grow, the versatility of calcium sulphate as an excipient will likely remain a key factor in its widespread use across the industry.

Tablets, Capsules in the Global Pharma Grade Calcium Sulphate Market:

The usage of Global Pharma Grade Calcium Sulphate in tablets and capsules is a testament to its versatility and importance in the pharmaceutical industry. In tablet formulations, calcium sulphate serves as a critical excipient, providing the necessary bulk and cohesion to form solid dosage forms. Its role as a filler and binder ensures that tablets maintain their shape and integrity during manufacturing, packaging, and storage. The compound's ability to absorb moisture also helps to protect the active ingredients from degradation, enhancing the stability and shelf life of the final product. In addition to its functional properties, calcium sulphate is valued for its inertness, meaning it does not react with other components in the formulation, ensuring the safety and efficacy of the medication. In capsule production, calcium sulphate is used to ensure uniformity and consistency in the final product. Its role as a filler helps to achieve the desired weight and volume of the capsule, while its binding properties ensure that the contents remain intact during handling and storage. The use of calcium sulphate in capsules also contributes to the overall stability of the formulation, protecting the active ingredients from environmental factors such as humidity and temperature fluctuations. The choice of calcium sulphate as an excipient in tablets and capsules is driven by its ability to enhance the quality and performance of the final product, making it an indispensable component of modern pharmaceutical manufacturing. As the demand for high-quality medications continues to rise, the role of calcium sulphate in ensuring the safety and efficacy of pharmaceutical products will remain a critical consideration for manufacturers worldwide.

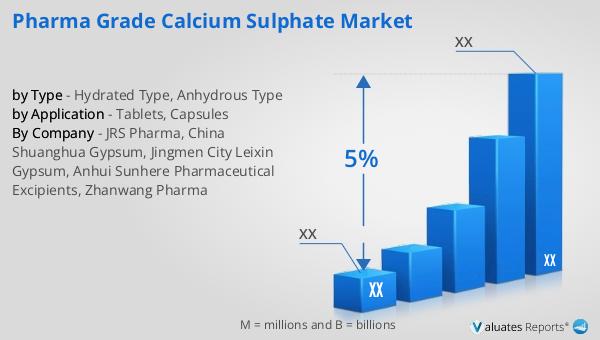

Global Pharma Grade Calcium Sulphate Market Outlook:

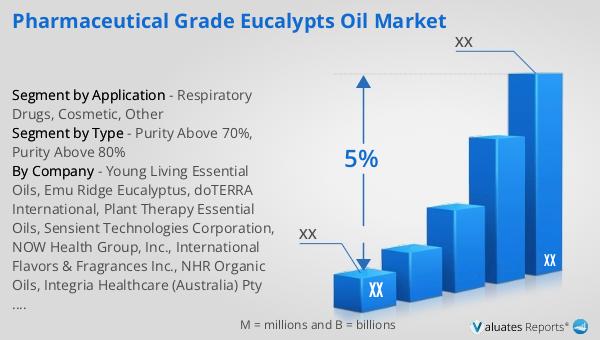

The outlook for the Global Pharma Grade Calcium Sulphate Market is closely tied to the broader trends in the pharmaceutical industry. As of 2022, the global pharmaceutical market is valued at approximately 1,475 billion USD, with an expected compound annual growth rate (CAGR) of 5% over the next six years. This growth is indicative of the increasing demand for pharmaceutical products worldwide, driven by factors such as an aging population, rising healthcare expenditures, and advancements in drug development technologies. In comparison, the chemical drug market has seen a steady increase, growing from 1,005 billion USD in 2018 to 1,094 billion USD in 2022. This growth highlights the ongoing demand for chemical-based medications, which continue to play a significant role in the treatment of various medical conditions. The expansion of the pharmaceutical and chemical drug markets underscores the importance of high-quality excipients like calcium sulphate, which are essential for the production of safe and effective medications. As the industry continues to evolve, the demand for pharma grade calcium sulphate is expected to grow, driven by its critical role in ensuring the quality and efficacy of pharmaceutical products. The market outlook for calcium sulphate is therefore closely aligned with the broader trends in the pharmaceutical industry, reflecting the ongoing need for innovative and reliable excipients in drug formulation and manufacturing.

| Report Metric | Details |

| Report Name | Pharma Grade Calcium Sulphate Market |

| CAGR | 5% |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | JRS Pharma, China Shuanghua Gypsum, Jingmen City Leixin Gypsum, Anhui Sunhere Pharmaceutical Excipients, Zhanwang Pharma |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |