What is Global Biobased Epoxy Nanocomposites Market?

The Global Biobased Epoxy Nanocomposites Market represents a significant advancement in the field of sustainable materials. These nanocomposites are derived from renewable resources, making them an eco-friendly alternative to traditional petroleum-based epoxy resins. The market is driven by the increasing demand for sustainable and environmentally friendly materials across various industries. Biobased epoxy nanocomposites are known for their excellent mechanical properties, thermal stability, and resistance to chemicals, which make them suitable for a wide range of applications. The use of nanotechnology enhances the properties of these materials, providing improved strength and durability. As industries continue to seek greener alternatives, the demand for biobased epoxy nanocomposites is expected to grow. This market is characterized by ongoing research and development efforts aimed at improving the performance and cost-effectiveness of these materials. With the global focus on reducing carbon footprints and promoting sustainability, the Global Biobased Epoxy Nanocomposites Market is poised for significant growth in the coming years. The market's expansion is supported by government initiatives and regulations promoting the use of biobased materials, as well as increasing consumer awareness about the environmental impact of traditional materials.

Sorbitol Polyglycidyl Ether, Biobased Carboxylic Acid, Microfibrillated Cellulose, Others in the Global Biobased Epoxy Nanocomposites Market:

Sorbitol Polyglycidyl Ether, Biobased Carboxylic Acid, Microfibrillated Cellulose, and other components play crucial roles in the Global Biobased Epoxy Nanocomposites Market. Sorbitol Polyglycidyl Ether is a biobased epoxy resin derived from sorbitol, a sugar alcohol obtained from glucose. It is known for its excellent adhesion properties and flexibility, making it suitable for applications requiring strong bonding and elasticity. This component is particularly valued in industries where flexibility and environmental sustainability are priorities. Biobased Carboxylic Acid is another essential component, derived from renewable resources such as plant oils and fats. It acts as a curing agent in epoxy systems, enhancing the thermal and mechanical properties of the nanocomposites. The use of biobased carboxylic acids contributes to the overall sustainability of the product, as they reduce reliance on fossil fuels and decrease the carbon footprint of the manufacturing process. Microfibrillated Cellulose (MFC) is a natural fiber obtained from plant sources, known for its high strength and lightweight properties. In the context of biobased epoxy nanocomposites, MFC acts as a reinforcing agent, improving the mechanical strength and toughness of the material. Its use in nanocomposites is driven by the need for materials that offer high performance while being environmentally friendly. The incorporation of MFC into epoxy systems enhances the overall sustainability of the product, as it is derived from renewable resources and is biodegradable. Other components in the Global Biobased Epoxy Nanocomposites Market include various natural fibers and fillers that contribute to the material's properties. These components are selected based on their ability to enhance specific characteristics of the nanocomposites, such as thermal stability, mechanical strength, and resistance to environmental factors. The development of these materials involves a careful balance between performance and sustainability, with ongoing research focused on optimizing the properties of biobased epoxy nanocomposites. The market for these materials is driven by the increasing demand for sustainable alternatives in various industries, including automotive, construction, and electronics. As the world moves towards more sustainable practices, the role of biobased components in epoxy nanocomposites is expected to grow, offering a viable solution to the challenges of traditional materials. The use of renewable resources in the production of these components not only reduces the environmental impact but also aligns with global efforts to promote sustainability and reduce carbon emissions. The Global Biobased Epoxy Nanocomposites Market is characterized by innovation and collaboration among industry players, with a focus on developing materials that meet the evolving needs of consumers and industries. As research and development efforts continue, the potential for new applications and improved performance of biobased epoxy nanocomposites is vast, promising a future where sustainable materials play a central role in various sectors.

Paints & Coatings, Electrical & Electronics, Construction, Adhesives, Others in the Global Biobased Epoxy Nanocomposites Market:

The Global Biobased Epoxy Nanocomposites Market finds extensive usage across several key industries, including Paints & Coatings, Electrical & Electronics, Construction, Adhesives, and others. In the Paints & Coatings industry, biobased epoxy nanocomposites are valued for their excellent adhesion, durability, and resistance to environmental factors. These properties make them ideal for use in protective coatings, where they provide long-lasting protection against corrosion, UV radiation, and chemical exposure. The use of biobased materials in this sector is driven by the increasing demand for eco-friendly coatings that reduce the environmental impact of painting processes. In the Electrical & Electronics industry, biobased epoxy nanocomposites are used for their excellent insulating properties and thermal stability. These materials are employed in the production of electronic components, such as circuit boards and encapsulants, where they provide reliable performance under varying environmental conditions. The use of biobased materials in this sector is driven by the need for sustainable alternatives that meet the stringent performance requirements of electronic applications. In the Construction industry, biobased epoxy nanocomposites are used for their high strength and durability. These materials are employed in the production of structural components, adhesives, and sealants, where they provide long-lasting performance and resistance to environmental factors. The use of biobased materials in this sector is driven by the increasing demand for sustainable construction practices that reduce the environmental impact of building processes. In the Adhesives industry, biobased epoxy nanocomposites are valued for their excellent bonding properties and flexibility. These materials are used in the production of adhesives for various applications, including automotive, aerospace, and consumer goods. The use of biobased materials in this sector is driven by the need for sustainable alternatives that provide reliable performance and reduce the environmental impact of adhesive production. Other industries that utilize biobased epoxy nanocomposites include automotive, aerospace, and consumer goods, where these materials offer a sustainable alternative to traditional materials. The use of biobased materials in these sectors is driven by the increasing demand for eco-friendly products that meet the performance requirements of various applications. As industries continue to seek sustainable alternatives, the demand for biobased epoxy nanocomposites is expected to grow, offering a viable solution to the challenges of traditional materials. The Global Biobased Epoxy Nanocomposites Market is characterized by innovation and collaboration among industry players, with a focus on developing materials that meet the evolving needs of consumers and industries. As research and development efforts continue, the potential for new applications and improved performance of biobased epoxy nanocomposites is vast, promising a future where sustainable materials play a central role in various sectors.

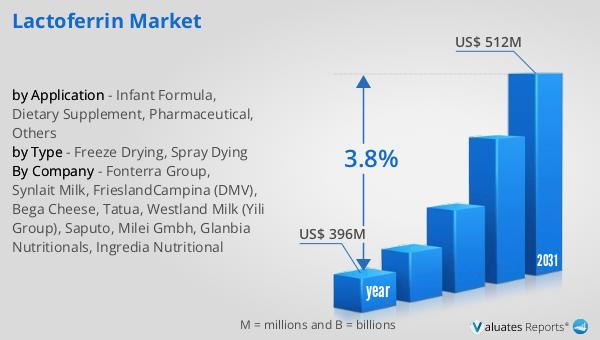

Global Biobased Epoxy Nanocomposites Market Outlook:

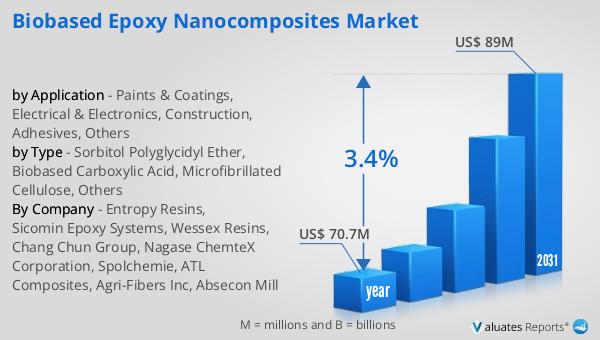

In 2024, the Global Biobased Epoxy Nanocomposites Market was valued at approximately $70.7 million, and it is anticipated to expand to a revised size of $89 million by 2031, reflecting a compound annual growth rate (CAGR) of 3.4% over the forecast period. The market is dominated by the top three players, who collectively hold about 80% of the market share. Europe emerges as the leading producer, accounting for around 59% of the production share, followed by North America and the Asia Pacific, which hold 32% and 9% of the production share, respectively. In terms of market size, Europe also leads with approximately 50% of the market share, while North America and the Asia Pacific follow with around 31% and 16% market share, respectively. This market outlook highlights the significant role of Europe in both production and market size, underscoring the region's commitment to sustainable materials and innovation in the biobased epoxy nanocomposites sector. The growth of this market is driven by the increasing demand for eco-friendly materials across various industries, as well as government initiatives and regulations promoting the use of biobased products. As the market continues to evolve, the focus remains on developing materials that offer high performance while reducing environmental impact, aligning with global efforts to promote sustainability and reduce carbon emissions.

| Report Metric | Details |

| Report Name | Biobased Epoxy Nanocomposites Market |

| Accounted market size in year | US$ 70.7 million |

| Forecasted market size in 2031 | US$ 89 million |

| CAGR | 3.4% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Entropy Resins, Sicomin Epoxy Systems, Wessex Resins, Chang Chun Group, Nagase ChemteX Corporation, Spolchemie, ATL Composites, Agri-Fibers Inc, Absecon Mill |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |