What is Cosmetic Plant Fragrance - Global Market?

Cosmetic plant fragrance refers to the scents derived from natural plant sources used in various cosmetic products. These fragrances are extracted from flowers, leaves, roots, and other parts of plants, offering a wide range of aromatic profiles that enhance the sensory experience of cosmetic products. The global market for cosmetic plant fragrances is vast and diverse, driven by the increasing consumer preference for natural and organic ingredients in personal care products. This market encompasses a variety of fragrance types, including single floral and compound floral scents, each offering unique olfactory experiences. The demand for these fragrances is fueled by their perceived health benefits, eco-friendliness, and the growing trend towards sustainable beauty products. As consumers become more conscious of the ingredients in their cosmetics, the market for plant-based fragrances continues to expand, offering opportunities for innovation and growth in the beauty industry. The global market for cosmetic plant fragrances is not only about the scents themselves but also about the stories and emotions they evoke, making them an integral part of the consumer's beauty ritual.

Single Floral, Compound Floral Scent in the Cosmetic Plant Fragrance - Global Market:

Single floral and compound floral scents are two primary categories within the cosmetic plant fragrance market, each offering distinct characteristics and appeal. Single floral scents are derived from a single type of flower, capturing the essence of that particular bloom. These fragrances are often simple yet elegant, highlighting the unique aroma of flowers like rose, jasmine, or lavender. Single floral scents are popular for their purity and the ability to evoke specific emotions or memories associated with the flower. For instance, rose is often associated with romance and luxury, while lavender is known for its calming and soothing properties. On the other hand, compound floral scents are a blend of multiple floral notes, creating a more complex and layered fragrance profile. These scents are crafted by combining different flowers to achieve a harmonious and balanced aroma that is greater than the sum of its parts. Compound floral fragrances are popular for their versatility and ability to cater to a wide range of preferences. They can be tailored to evoke different moods or atmospheres, from fresh and invigorating to warm and sensual. The creation of compound floral scents requires a deep understanding of fragrance composition and the ability to balance various floral notes to achieve the desired effect. In the global market, both single and compound floral scents play a crucial role in the development of cosmetic products, offering consumers a diverse range of options to suit their personal preferences. As the demand for natural and plant-based fragrances continues to grow, the market for single and compound floral scents is expected to expand, driven by innovation and the desire for unique and personalized fragrance experiences.

Makeup Products, Skin Care Products, Hair Care Products, Personal Care Products, Others in the Cosmetic Plant Fragrance - Global Market:

Cosmetic plant fragrances are widely used across various product categories, including makeup, skincare, hair care, personal care, and others. In makeup products, these fragrances are often added to enhance the overall sensory experience, making the application process more enjoyable. For instance, a foundation or lipstick with a subtle floral scent can provide a pleasant aroma that complements the visual appeal of the product. In skincare products, plant-based fragrances are used not only for their aromatic qualities but also for their potential skin benefits. Ingredients like chamomile, rose, and lavender are known for their soothing and calming properties, making them popular choices in creams, lotions, and serums. These fragrances can enhance the therapeutic experience of skincare routines, promoting relaxation and well-being. In hair care products, cosmetic plant fragrances are used to impart a fresh and pleasant scent to shampoos, conditioners, and styling products. They can also provide additional benefits, such as promoting scalp health or adding shine to the hair. Personal care products, such as deodorants, body washes, and bath products, often incorporate plant-based fragrances to create a refreshing and invigorating experience. These scents can help mask body odors and leave a lingering fragrance that boosts confidence and freshness throughout the day. Beyond these categories, cosmetic plant fragrances are also used in niche products like aromatherapy oils, candles, and home fragrances, where the focus is on creating a specific ambiance or mood. The versatility and appeal of plant-based fragrances make them a valuable addition to a wide range of products, catering to the diverse preferences and needs of consumers worldwide.

Cosmetic Plant Fragrance - Global Market Outlook:

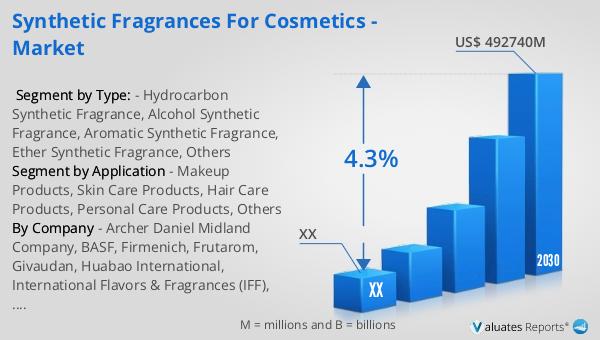

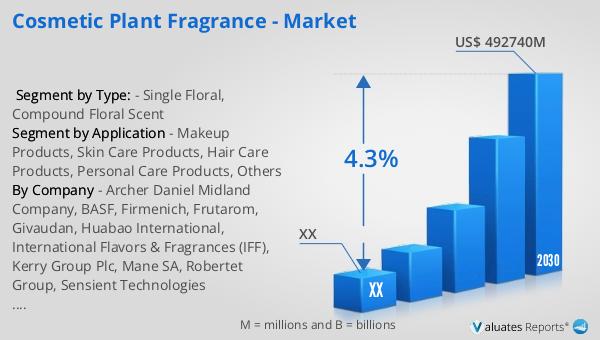

The global market for cosmetic plant fragrances was valued at approximately $364.52 billion in 2023. This market is projected to grow significantly, reaching an estimated size of $492.74 billion by 2030. This growth represents a compound annual growth rate (CAGR) of 4.3% during the forecast period from 2024 to 2030. The increasing demand for natural and organic ingredients in cosmetic products is a key driver of this market expansion. Consumers are becoming more conscious of the ingredients in their beauty products, seeking options that are not only effective but also environmentally friendly and sustainable. This shift in consumer preferences is encouraging manufacturers to innovate and develop new plant-based fragrances that meet these demands. The market's growth is also supported by the rising popularity of personalized and unique fragrance experiences, as consumers seek products that reflect their individuality and lifestyle. As the market continues to evolve, there are ample opportunities for companies to capitalize on these trends and expand their offerings in the cosmetic plant fragrance sector.

| Report Metric | Details |

| Report Name | Cosmetic Plant Fragrance - Market |

| Forecasted market size in 2030 | US$ 492740 million |

| CAGR | 4.3% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Archer Daniel Midland Company, BASF, Firmenich, Frutarom, Givaudan, Huabao International, International Flavors & Fragrances (IFF), Kerry Group Plc, Mane SA, Robertet Group, Sensient Technologies Corporation, Solvay S.A., Symrise, T. Hasegawa, Takasago International Corporation |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |