What is Photoelectric Level Sensor - Global Market?

Photoelectric level sensors are sophisticated devices used to detect the level of substances, typically liquids, within a container or system. These sensors operate based on the principle of photoelectric effect, where a light beam is emitted and then detected by a receiver. When the light beam is interrupted or reflected by the substance, the sensor can determine the level of the material. The global market for photoelectric level sensors is expanding due to their high precision, reliability, and non-contact measurement capabilities. These sensors are crucial in various industries, including manufacturing, food and beverage, pharmaceuticals, and automotive, where accurate level measurement is essential for maintaining quality and efficiency. The increasing demand for automation and the need for precise control in industrial processes are driving the growth of this market. Additionally, advancements in technology are enhancing the functionality and application range of these sensors, making them more versatile and efficient. As industries continue to evolve and require more sophisticated monitoring solutions, the role of photoelectric level sensors is becoming increasingly significant. Their ability to provide accurate, real-time data helps in optimizing processes, reducing waste, and ensuring safety, thereby contributing to their growing adoption across different sectors.

Retroreflective, Diffuse in the Photoelectric Level Sensor - Global Market:

Retroreflective and diffuse sensors are two types of photoelectric level sensors that play a crucial role in the global market. Retroreflective sensors work by emitting a light beam towards a reflector, which then sends the light back to the sensor. When an object interrupts this light path, the sensor detects the change and determines the presence or level of the object. This type of sensor is highly effective in applications where the object has a reflective surface or where the sensor needs to detect transparent objects. On the other hand, diffuse sensors operate by emitting a light beam that reflects off the surface of the object itself. The sensor then detects the reflected light to determine the object's presence or level. Diffuse sensors are particularly useful in detecting objects with varying colors, textures, or materials, as they rely on the reflection from the object rather than a separate reflector. Both retroreflective and diffuse sensors offer unique advantages and are chosen based on the specific requirements of the application. In industrial manufacturing, these sensors are used for detecting the presence of materials on conveyor belts, ensuring that production lines run smoothly and efficiently. In the food and beverage industry, they help in maintaining the correct levels of ingredients in mixing tanks, ensuring product consistency and quality. The pharmaceutical industry relies on these sensors for precise measurement of liquid levels in vials and containers, which is critical for dosage accuracy and safety. In the automotive and transportation sectors, photoelectric level sensors are used to monitor fluid levels in vehicles, such as oil, coolant, and fuel, ensuring optimal performance and preventing potential damage. The versatility and reliability of retroreflective and diffuse sensors make them indispensable tools in various industries, contributing to the overall growth of the photoelectric level sensor market. As technology continues to advance, these sensors are expected to become even more sophisticated, offering enhanced features and capabilities that meet the evolving needs of different sectors. Their ability to provide accurate, real-time data is essential for optimizing processes, reducing waste, and ensuring safety, making them a valuable asset in modern industrial applications.

Industrial Manufacturing, Food and Beverage, Pharmaceutical, Automotive and Transportation, Others in the Photoelectric Level Sensor - Global Market:

Photoelectric level sensors are widely used across various industries due to their precision and reliability. In industrial manufacturing, these sensors are essential for monitoring the levels of raw materials and finished products. They ensure that production processes run smoothly by providing accurate data on material levels, which helps in maintaining consistent product quality and reducing waste. In the food and beverage industry, photoelectric level sensors play a critical role in maintaining the correct levels of ingredients in mixing tanks and storage containers. This ensures that the final products meet quality standards and comply with safety regulations. The pharmaceutical industry relies heavily on these sensors for precise measurement of liquid levels in vials, syringes, and other containers. Accurate level measurement is crucial for ensuring the correct dosage and maintaining the safety and efficacy of pharmaceutical products. In the automotive and transportation sectors, photoelectric level sensors are used to monitor fluid levels in vehicles, such as oil, coolant, and fuel. This helps in preventing potential damage to the vehicle and ensures optimal performance. Additionally, these sensors are used in various other industries, such as chemical processing, water treatment, and packaging, where accurate level measurement is essential for maintaining process efficiency and safety. The versatility and reliability of photoelectric level sensors make them an indispensable tool in modern industrial applications. As technology continues to advance, these sensors are expected to become even more sophisticated, offering enhanced features and capabilities that meet the evolving needs of different sectors. Their ability to provide accurate, real-time data is essential for optimizing processes, reducing waste, and ensuring safety, making them a valuable asset in various industries.

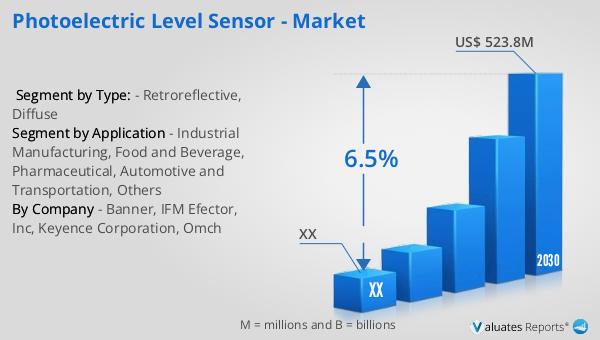

Photoelectric Level Sensor - Global Market Outlook:

The global market for photoelectric level sensors was valued at approximately $34 million in 2023. It is projected to grow significantly, reaching an estimated $523.8 million by 2030, with a compound annual growth rate (CAGR) of 6.5% during the forecast period from 2024 to 2030. This growth is driven by the increasing demand for precise and reliable level measurement solutions across various industries. As science and technology continue to advance, photoelectric level sensors are gaining more attention due to their ability to provide accurate, real-time data. These sensors are becoming increasingly important in industries such as manufacturing, food and beverage, pharmaceuticals, and automotive, where precise level measurement is crucial for maintaining quality and efficiency. The growing trend towards automation and the need for sophisticated monitoring solutions are further contributing to the expansion of the photoelectric level sensor market. As industries continue to evolve and require more advanced technologies, the demand for photoelectric level sensors is expected to rise, driving market growth and innovation. The ability of these sensors to optimize processes, reduce waste, and ensure safety makes them a valuable asset in modern industrial applications.

| Report Metric | Details |

| Report Name | Photoelectric Level Sensor - Market |

| Forecasted market size in 2030 | US$ 523.8 million |

| CAGR | 6.5% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Banner, IFM Efector, Inc, Keyence Corporation, Omch |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |