What is MEMS-based Pressure Sensors - Global Market?

MEMS-based pressure sensors are a fascinating component of the global market, representing a blend of micro-electromechanical systems (MEMS) technology and pressure sensing capabilities. These sensors are designed to measure pressure changes in gases or liquids and convert them into an electrical signal. The global market for MEMS-based pressure sensors has been expanding due to their wide range of applications across various industries. These sensors are known for their small size, high accuracy, and reliability, making them ideal for integration into compact devices. They are used in automotive systems for monitoring tire pressure, in medical devices for measuring blood pressure, and in consumer electronics for enhancing user experience. The demand for these sensors is driven by the increasing need for precise pressure measurement in advanced technologies and the growing trend of miniaturization in electronic devices. As industries continue to innovate and develop new applications, the market for MEMS-based pressure sensors is expected to grow, offering new opportunities for manufacturers and developers. The versatility and adaptability of these sensors make them a critical component in the advancement of technology across multiple sectors.

MEMS Capacitive Pressure Sensors, MEMS Piezoresistive Pressure Sensors, Others in the MEMS-based Pressure Sensors - Global Market:

MEMS capacitive pressure sensors are a type of MEMS-based pressure sensor that operates on the principle of capacitance change. These sensors consist of a diaphragm and a fixed plate, forming a capacitor. When pressure is applied, the diaphragm deflects, causing a change in capacitance that is measured and converted into an electrical signal. MEMS capacitive pressure sensors are known for their high sensitivity, low power consumption, and excellent stability over a wide temperature range. They are widely used in applications where precise pressure measurement is crucial, such as in barometric pressure sensing and altimeters. On the other hand, MEMS piezoresistive pressure sensors work on the principle of piezoresistance, where the resistance of a material changes when mechanical stress is applied. These sensors typically consist of a diaphragm with piezoresistive elements embedded in it. When pressure is applied, the diaphragm deforms, causing a change in resistance that is measured and converted into an electrical signal. MEMS piezoresistive pressure sensors are valued for their high accuracy, linearity, and ability to operate in harsh environments. They are commonly used in automotive applications, such as in engine control systems and tire pressure monitoring. Apart from capacitive and piezoresistive types, there are other MEMS-based pressure sensors that utilize different sensing principles, such as resonant and optical methods. Resonant pressure sensors measure pressure by detecting changes in the resonant frequency of a vibrating element, while optical pressure sensors use changes in light properties to measure pressure. These alternative methods offer unique advantages, such as high precision and immunity to electromagnetic interference, making them suitable for specialized applications. The diversity in MEMS-based pressure sensor technologies allows for a wide range of applications, catering to the specific needs of different industries. As technology continues to advance, the development of new and improved MEMS-based pressure sensors is expected to drive further growth in the global market.

Automotive, Consumer Electronics, Medical, Industrial, Aerospace & Defense, Others in the MEMS-based Pressure Sensors - Global Market:

MEMS-based pressure sensors have found extensive usage across various sectors due to their precision, reliability, and compact size. In the automotive industry, these sensors are crucial for enhancing vehicle safety and performance. They are used in tire pressure monitoring systems to ensure optimal tire pressure, which improves fuel efficiency and reduces the risk of accidents. Additionally, MEMS-based pressure sensors are employed in engine control systems to monitor and optimize engine performance, contributing to reduced emissions and improved fuel economy. In the realm of consumer electronics, MEMS-based pressure sensors are integrated into devices such as smartphones and wearables to enhance user experience. They enable features like barometric altitude detection, which is used in fitness tracking and navigation applications. In the medical field, these sensors play a vital role in monitoring critical parameters such as blood pressure and respiratory pressure, aiding in the diagnosis and management of various health conditions. Their small size and high accuracy make them ideal for use in portable and wearable medical devices. The industrial sector also benefits from MEMS-based pressure sensors, where they are used in process control and monitoring applications. They help ensure the safe and efficient operation of machinery and equipment by providing accurate pressure measurements. In aerospace and defense, MEMS-based pressure sensors are used in applications such as altitude measurement and cabin pressure monitoring, contributing to the safety and performance of aircraft. The versatility of MEMS-based pressure sensors allows them to be used in a wide range of other applications, including environmental monitoring and scientific research. As industries continue to innovate and develop new technologies, the demand for MEMS-based pressure sensors is expected to grow, driving further advancements in this field.

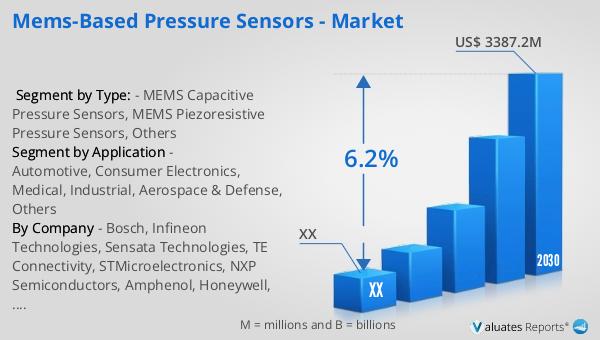

MEMS-based Pressure Sensors - Global Market Outlook:

The global market for MEMS-based pressure sensors was valued at approximately US$ 2,227 million in 2023. Looking ahead, it is projected to reach a revised size of US$ 3,387.2 million by 2030, reflecting a compound annual growth rate (CAGR) of 6.2% during the forecast period from 2024 to 2030. This growth trajectory highlights the increasing adoption and advancements in MEMS-based pressure sensors across various industries. The demand for these sensors is driven by their ability to provide accurate and reliable pressure measurements in a compact form factor, making them suitable for a wide range of applications. As industries continue to innovate and develop new technologies, the need for precise pressure sensing solutions is expected to rise, further fueling the growth of the MEMS-based pressure sensors market. The ongoing advancements in MEMS technology, coupled with the growing trend of miniaturization in electronic devices, are anticipated to create new opportunities for manufacturers and developers in this market. As a result, the global market for MEMS-based pressure sensors is poised for significant growth in the coming years, driven by the increasing demand for advanced pressure sensing solutions across various sectors.

| Report Metric | Details |

| Report Name | MEMS-based Pressure Sensors - Market |

| Forecasted market size in 2030 | US$ 3387.2 million |

| CAGR | 6.2% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Bosch, Infineon Technologies, Sensata Technologies, TE Connectivity, STMicroelectronics, NXP Semiconductors, Amphenol, Honeywell, Kulite, Denso, Omron, TDK, Continental, KELLER, Melexis, Alps Alpine, All Sensors, Fuji Electric, Merit Sensor, Panasonic, Beijing Beetech, MEMSensing Microsystems, NOVOSENSE Microelectronics |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |