What is Disposable Surgical Scrub Brush - Global Market?

Disposable surgical scrub brushes are essential tools in the healthcare industry, designed to maintain hygiene and prevent infections during surgical procedures. These brushes are typically used by medical professionals to clean their hands and forearms before surgery, ensuring that any potential contaminants are removed. The global market for disposable surgical scrub brushes is driven by the increasing awareness of infection control and the growing number of surgical procedures worldwide. These brushes are made from materials that are safe for the skin and are often impregnated with antiseptic solutions to enhance their effectiveness. The convenience of disposable scrub brushes lies in their single-use nature, which eliminates the risk of cross-contamination between patients. As healthcare standards continue to rise, the demand for these brushes is expected to grow, reflecting their critical role in maintaining surgical hygiene. The market is characterized by a variety of products, each designed to meet specific needs, from basic brushes to those with advanced antiseptic properties. This diversity allows healthcare providers to choose the most appropriate tools for their specific requirements, ensuring optimal patient safety and care.

Povidone-iodine Scrub Brushes, Povidone-iodine-free Scrub Brushes in the Disposable Surgical Scrub Brush - Global Market:

Povidone-iodine scrub brushes and povidone-iodine-free scrub brushes represent two significant categories within the disposable surgical scrub brush market. Povidone-iodine scrub brushes are infused with an antiseptic solution known for its broad-spectrum antimicrobial activity. This solution is effective against a wide range of pathogens, including bacteria, viruses, and fungi, making it a popular choice in surgical settings where infection control is paramount. The use of povidone-iodine in scrub brushes ensures that healthcare professionals can achieve a high level of cleanliness, reducing the risk of postoperative infections. These brushes are particularly favored in environments where the risk of infection is high, such as in surgeries involving immunocompromised patients or in areas with a high prevalence of antibiotic-resistant bacteria. On the other hand, povidone-iodine-free scrub brushes cater to individuals who may have allergies or sensitivities to iodine. These brushes are often impregnated with alternative antiseptic agents, such as chlorhexidine or alcohol-based solutions, which also provide effective antimicrobial action. The choice between povidone-iodine and povidone-iodine-free scrub brushes often depends on the specific needs of the healthcare facility and the preferences of the medical staff. Some facilities may opt for povidone-iodine-free options to accommodate patients and staff with iodine sensitivities, while others may prefer the proven efficacy of povidone-iodine. The availability of both types of scrub brushes in the market ensures that healthcare providers can select the most suitable product for their infection control protocols. Additionally, the development of povidone-iodine-free scrub brushes reflects the industry's commitment to innovation and patient safety, as manufacturers strive to offer products that meet diverse needs without compromising on effectiveness. As the global market for disposable surgical scrub brushes continues to expand, the demand for both povidone-iodine and povidone-iodine-free options is expected to grow, driven by the increasing emphasis on infection prevention and control in healthcare settings. This growth is further supported by advancements in manufacturing technologies, which enable the production of high-quality scrub brushes that meet stringent regulatory standards. Overall, the presence of both povidone-iodine and povidone-iodine-free scrub brushes in the market highlights the importance of offering versatile solutions that cater to the varied requirements of healthcare professionals and patients alike.

Hospital, Clinic, Others in the Disposable Surgical Scrub Brush - Global Market:

The usage of disposable surgical scrub brushes is prevalent across various healthcare settings, including hospitals, clinics, and other medical facilities. In hospitals, these brushes are an integral part of the pre-surgical preparation process. Surgeons, nurses, and other operating room staff use them to thoroughly clean their hands and forearms, ensuring that they are free from any potential contaminants before entering the sterile environment of the operating room. The use of disposable scrub brushes in hospitals is crucial for maintaining high standards of hygiene and preventing surgical site infections, which can have serious implications for patient outcomes. In clinics, disposable surgical scrub brushes are used in a similar manner, albeit on a smaller scale. Clinics that perform minor surgical procedures or invasive diagnostic tests rely on these brushes to maintain a sterile environment and protect patients from infections. The convenience and effectiveness of disposable scrub brushes make them a preferred choice in clinics, where resources and space may be limited compared to larger hospital settings. Additionally, the use of disposable brushes in clinics helps streamline the workflow, as they eliminate the need for cleaning and sterilizing reusable brushes, saving time and reducing the risk of cross-contamination. Beyond hospitals and clinics, disposable surgical scrub brushes find applications in other healthcare settings, such as dental offices, veterinary clinics, and outpatient surgical centers. In dental offices, for example, these brushes are used by dental surgeons and hygienists to ensure that their hands are thoroughly cleaned before performing procedures. Similarly, in veterinary clinics, disposable scrub brushes are used to maintain hygiene during animal surgeries, protecting both the animals and the veterinary staff from infections. The versatility of disposable surgical scrub brushes makes them an essential tool in any setting where surgical or invasive procedures are performed. Their single-use nature ensures that each procedure is conducted with a fresh, sterile brush, minimizing the risk of infection and enhancing patient safety. As healthcare facilities continue to prioritize infection control, the demand for disposable surgical scrub brushes is expected to remain strong across various sectors, reflecting their vital role in maintaining hygiene and preventing infections.

Disposable Surgical Scrub Brush - Global Market Outlook:

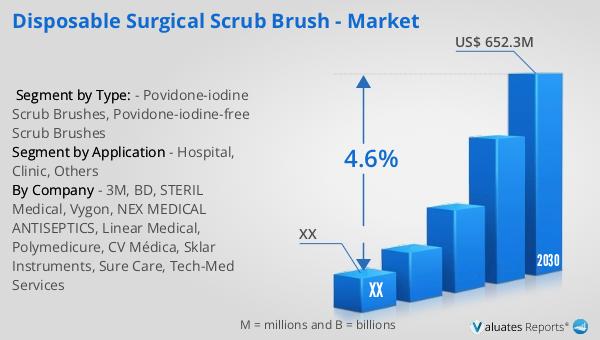

The global market for disposable surgical scrub brushes was valued at approximately $473 million in 2023. It is projected to grow to a revised size of $652.3 million by 2030, with a compound annual growth rate (CAGR) of 4.6% during the forecast period from 2024 to 2030. This growth is indicative of the increasing emphasis on infection control and the rising number of surgical procedures worldwide. The market for disposable surgical scrub brushes is a subset of the broader medical devices market, which was estimated to be worth $603 billion in 2023. The medical devices market is expected to grow at a CAGR of 5% over the next six years, reflecting the ongoing advancements in healthcare technology and the increasing demand for innovative medical solutions. The growth of the disposable surgical scrub brush market is driven by several factors, including the rising awareness of the importance of hygiene in healthcare settings, the increasing prevalence of hospital-acquired infections, and the growing number of surgical procedures being performed globally. As healthcare facilities continue to prioritize infection prevention and control, the demand for disposable surgical scrub brushes is expected to increase, contributing to the overall growth of the market. The market's expansion is further supported by advancements in manufacturing technologies, which enable the production of high-quality scrub brushes that meet stringent regulatory standards. As a result, the global market for disposable surgical scrub brushes is poised for steady growth, driven by the increasing emphasis on patient safety and infection control in healthcare settings.

| Report Metric | Details |

| Report Name | Disposable Surgical Scrub Brush - Market |

| Forecasted market size in 2030 | US$ 652.3 million |

| CAGR | 4.6% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | 3M, BD, STERIL Medical, Vygon, NEX MEDICAL ANTISEPTICS, Linear Medical, Polymedicure, CV Médica, Sklar Instruments, Sure Care, Tech-Med Services |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |