What is Special Equipment for Chloralkali - Global Market?

Special equipment for the chloralkali industry plays a crucial role in the production of essential chemicals like chlorine, caustic soda, and hydrogen. These chemicals are fundamental to various industrial processes, and their production requires specialized equipment to ensure efficiency, safety, and environmental compliance. The global market for this equipment is driven by the demand for these chemicals across multiple industries, including water treatment, pharmaceuticals, and manufacturing. The equipment used in the chloralkali process includes electrolytic cells, compressors, and other machinery designed to handle the corrosive nature of the chemicals involved. The market is characterized by technological advancements aimed at improving energy efficiency and reducing environmental impact. Companies in this sector are continuously innovating to meet stringent regulatory standards and to cater to the growing demand for chloralkali products. As industries expand and environmental regulations become more stringent, the need for advanced and reliable chloralkali equipment is expected to grow, making this a dynamic and evolving market.

Electrolytic Cell, Compressor in the Special Equipment for Chloralkali - Global Market:

Electrolytic cells are at the heart of the chloralkali process, serving as the primary equipment for the electrolysis of saltwater to produce chlorine, caustic soda, and hydrogen. These cells are designed to handle the harsh conditions of the electrolysis process, which involves high temperatures and corrosive materials. The efficiency of an electrolytic cell is crucial as it directly impacts the overall productivity and energy consumption of the chloralkali plant. Modern electrolytic cells are engineered to maximize output while minimizing energy usage, which is a significant cost factor in chloralkali production. Innovations in cell design, such as the use of advanced membrane technology, have led to improvements in the separation of chlorine and caustic soda, enhancing the purity and yield of the products. Compressors, on the other hand, are essential for handling the gases produced during the chloralkali process. They are used to compress and transport chlorine gas, which is highly reactive and requires careful handling to prevent leaks and ensure safety. The design of compressors for chloralkali applications focuses on durability and resistance to corrosion, given the aggressive nature of chlorine gas. Advanced materials and coatings are often employed to extend the lifespan of these compressors and reduce maintenance costs. The global market for electrolytic cells and compressors in the chloralkali industry is influenced by several factors, including technological advancements, regulatory requirements, and the demand for chloralkali products. Companies are investing in research and development to create more efficient and environmentally friendly equipment, which is crucial for meeting the increasing demand for sustainable industrial practices. The market is also shaped by the need for equipment that can operate reliably under the challenging conditions of chloralkali production, ensuring safety and compliance with environmental standards. As the industry evolves, the focus on energy efficiency and sustainability is expected to drive further innovations in electrolytic cell and compressor technology, making them integral components of the chloralkali market.

Chemical Industry, Textile Industry, Papermaking Industry in the Special Equipment for Chloralkali - Global Market:

The special equipment used in the chloralkali industry finds applications across various sectors, including the chemical, textile, and papermaking industries. In the chemical industry, chloralkali products such as chlorine and caustic soda are essential raw materials for the production of a wide range of chemicals, including PVC, solvents, and disinfectants. The equipment used in this industry must be capable of handling large volumes of corrosive materials while maintaining high levels of efficiency and safety. Advanced electrolytic cells and compressors are crucial for ensuring the consistent production of high-purity chemicals, which are vital for maintaining the quality and performance of chemical products. In the textile industry, chloralkali products are used in processes such as bleaching and dyeing. The equipment used in these applications must be able to withstand the harsh conditions of textile processing, where chemicals are used to alter the properties of fabrics. The reliability and efficiency of chloralkali equipment are critical for ensuring the quality and consistency of textile products, which are subject to stringent quality standards. In the papermaking industry, chloralkali products are used in the production of paper pulp and the treatment of wastewater. The equipment used in this industry must be capable of handling the corrosive nature of the chemicals involved while ensuring the efficient and environmentally friendly operation of papermaking processes. The use of advanced chloralkali equipment helps to reduce the environmental impact of papermaking by minimizing waste and improving the efficiency of chemical usage. Overall, the demand for special equipment in the chloralkali industry is driven by the need for reliable and efficient machinery that can meet the diverse requirements of these industries while ensuring compliance with environmental and safety regulations.

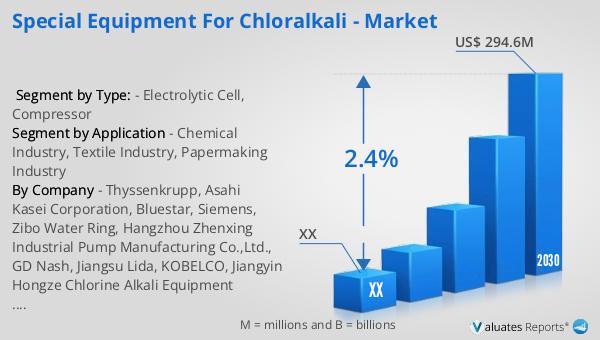

Special Equipment for Chloralkali - Global Market Outlook:

The global market for special equipment used in the chloralkali industry was valued at approximately $248.7 million in 2023. This market is projected to grow to a revised size of around $294.6 million by 2030, reflecting a compound annual growth rate (CAGR) of 2.4% over the forecast period from 2024 to 2030. This growth is indicative of the increasing demand for chloralkali products across various industries, as well as the need for advanced equipment that can enhance production efficiency and meet stringent environmental standards. The market's expansion is driven by technological advancements in equipment design, which aim to improve energy efficiency and reduce the environmental impact of chloralkali production. Companies operating in this market are focusing on innovation and sustainability to cater to the evolving needs of their customers and to comply with regulatory requirements. As industries continue to expand and environmental regulations become more stringent, the demand for reliable and efficient chloralkali equipment is expected to rise, contributing to the market's growth. This market outlook highlights the importance of investing in advanced equipment and technology to remain competitive in the chloralkali industry and to meet the growing demand for sustainable industrial practices.

| Report Metric | Details |

| Report Name | Special Equipment for Chloralkali - Market |

| Forecasted market size in 2030 | US$ 294.6 million |

| CAGR | 2.4% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Thyssenkrupp, Asahi Kasei Corporation, Bluestar, Siemens, Zibo Water Ring, Hangzhou Zhenxing Industrial Pump Manufacturing Co.,Ltd., GD Nash, Jiangsu Lida, KOBELCO, Jiangyin Hongze Chlorine Alkali Equipment Producing Co.,Ltd |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |