What is Global Refractory High-Entropy Alloys Market?

The Global Refractory High-Entropy Alloys Market is a specialized segment within the broader materials science and engineering industry. High-entropy alloys (HEAs) are a relatively new class of materials that consist of five or more principal elements mixed in near-equal proportions. Refractory HEAs are a subset of these alloys that are designed to withstand extremely high temperatures and harsh environments, making them ideal for applications in industries such as aerospace, defense, and energy. These alloys exhibit exceptional mechanical properties, including high strength, toughness, and resistance to oxidation and corrosion. The market for these advanced materials is driven by the increasing demand for high-performance materials that can operate under extreme conditions. As industries continue to push the boundaries of technology and performance, the need for materials that can endure these challenges grows, thereby fueling the demand for refractory HEAs. The market is characterized by ongoing research and development efforts aimed at discovering new alloy compositions and improving existing ones to enhance their performance and cost-effectiveness.

Powder, Rod, Plate, Others in the Global Refractory High-Entropy Alloys Market:

In the Global Refractory High-Entropy Alloys Market, products are typically categorized into various forms such as powder, rod, plate, and others. Each form has its unique applications and advantages, catering to different industrial needs. Powder form is particularly significant in additive manufacturing and 3D printing technologies. The fine granules of refractory HEAs can be precisely controlled and deposited layer by layer to create complex geometries that would be challenging or impossible to achieve with traditional manufacturing methods. This makes powder form highly desirable for producing intricate components in aerospace, biomedical, and other high-tech industries. Rod form, on the other hand, is often used in applications requiring high tensile strength and durability. These rods can be machined into various shapes and sizes, making them suitable for structural components in aerospace and defense sectors. The high melting point and excellent mechanical properties of refractory HEAs in rod form make them ideal for use in environments where traditional materials would fail. Plate form is another crucial category, often used in applications requiring large, flat surfaces with high strength and resistance to wear and corrosion. These plates can be used in heat exchangers, protective barriers, and other industrial applications where durability and longevity are paramount. The versatility of plate form allows for its use in a wide range of industries, from energy to automotive. Other forms of refractory HEAs include wires, foils, and custom shapes, each tailored to specific applications. Wires made from refractory HEAs are used in high-temperature electrical applications, while foils can be used in shielding and protective layers. Custom shapes are often designed for specialized applications, leveraging the unique properties of refractory HEAs to meet specific industrial challenges. The ability to produce these alloys in various forms enhances their applicability across different sectors, driving the growth of the Global Refractory High-Entropy Alloys Market.

Aerospace, 3D Printing, Biomedical, Others in the Global Refractory High-Entropy Alloys Market:

The usage of Global Refractory High-Entropy Alloys Market spans several critical areas, including aerospace, 3D printing, biomedical, and others. In the aerospace industry, refractory HEAs are highly valued for their ability to withstand extreme temperatures and mechanical stresses. These alloys are used in the manufacturing of turbine blades, engine components, and other critical parts that require high strength and resistance to oxidation and corrosion. The superior performance of refractory HEAs in harsh environments makes them ideal for aerospace applications, where safety and reliability are paramount. In the realm of 3D printing, refractory HEAs offer unique advantages due to their excellent mechanical properties and versatility. The powder form of these alloys is particularly suitable for additive manufacturing processes, enabling the production of complex and high-performance components. This has significant implications for industries such as aerospace, automotive, and medical devices, where precision and material performance are crucial. In the biomedical field, refractory HEAs are being explored for their potential in creating durable and biocompatible implants and medical devices. The high strength and corrosion resistance of these alloys make them suitable for long-term implants, such as joint replacements and dental implants. Additionally, their ability to withstand sterilization processes without degrading makes them ideal for medical applications. Other areas where refractory HEAs find usage include the energy sector, where they are used in high-temperature applications such as nuclear reactors and power plants. The exceptional properties of these alloys make them suitable for components that must endure extreme conditions, contributing to the efficiency and safety of energy systems. The versatility and superior performance of refractory HEAs across various industries underscore their growing importance in the Global Refractory High-Entropy Alloys Market.

Global Refractory High-Entropy Alloys Market Outlook:

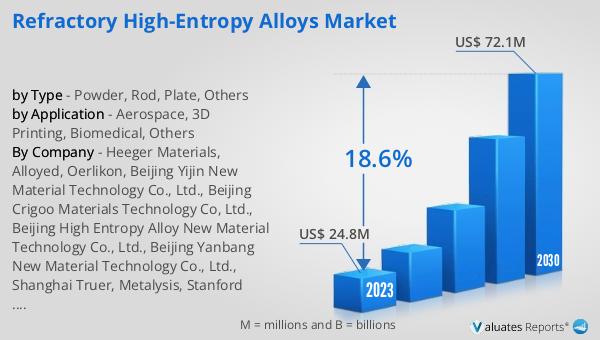

The global Refractory High-Entropy Alloys market was valued at US$ 24.8 million in 2023 and is anticipated to reach US$ 72.1 million by 2030, witnessing a CAGR of 18.6% during the forecast period 2024-2030. This significant growth reflects the increasing demand for high-performance materials capable of operating under extreme conditions. The market's expansion is driven by advancements in technology and the continuous push for innovation in industries such as aerospace, defense, and energy. As these industries seek materials that offer superior mechanical properties, high strength, and resistance to oxidation and corrosion, the demand for refractory HEAs is expected to rise. The projected growth rate of 18.6% CAGR indicates a robust market trajectory, highlighting the importance of ongoing research and development efforts to discover new alloy compositions and improve existing ones. The market outlook suggests a promising future for refractory HEAs, with their applications expanding across various sectors and driving the need for advanced materials that can meet the challenges of modern technology and industrial demands.

| Report Metric | Details |

| Report Name | Refractory High-Entropy Alloys Market |

| Accounted market size in 2023 | US$ 24.8 million |

| Forecasted market size in 2030 | US$ 72.1 million |

| CAGR | 18.6% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Heeger Materials, Alloyed, Oerlikon, Beijing Yijin New Material Technology Co., Ltd., Beijing Crigoo Materials Technology Co, Ltd., Beijing High Entropy Alloy New Material Technology Co., Ltd., Beijing Yanbang New Material Technology Co., Ltd., Shanghai Truer, Metalysis, Stanford Advanced Materials, ATT Advanced Elemental Materials Co., Ltd., Jiangxi Yongtai Powder Metallurgy Co., Ltd., STARDUST, GREES (BEIJING) NEW MATERIAL TECHNOLOGY CO., LTD. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |