What is Global Double Layer DIN Rail Terminal Blocks Market?

The Global Double Layer DIN Rail Terminal Blocks Market refers to the worldwide industry focused on the production, distribution, and utilization of double-layer terminal blocks that are mounted on DIN rails. These terminal blocks are essential components in electrical and electronic systems, providing a secure and organized method for connecting multiple wires. The "double layer" aspect means that these terminal blocks have two levels of connection points, which allows for more compact and efficient wiring solutions. They are widely used in various industries, including power distribution, industrial automation, and control systems, due to their reliability, ease of installation, and ability to handle high current loads. The market encompasses a range of products from different manufacturers, each offering various features and specifications to meet the diverse needs of end-users. The growth of this market is driven by the increasing demand for efficient and reliable electrical connections in industrial and commercial applications.

Spring-Cage Connection, Screw Connection in the Global Double Layer DIN Rail Terminal Blocks Market:

Spring-cage connection and screw connection are two prevalent types of connection technologies used in the Global Double Layer DIN Rail Terminal Blocks Market. Spring-cage connection technology utilizes a spring mechanism to secure the wire in place. This method is known for its quick and easy installation process, as it does not require any tools to connect the wires. The spring mechanism ensures a consistent and reliable connection, which is resistant to vibration and thermal cycling. This makes spring-cage connections particularly suitable for applications where maintenance and downtime need to be minimized. On the other hand, screw connection technology involves using a screw to clamp the wire into the terminal block. This method provides a very strong and secure connection, which is ideal for applications that require high mechanical stability and where the connections are not frequently changed. Screw connections are also known for their ability to handle larger wire sizes and higher current loads. Both connection technologies have their own advantages and are chosen based on the specific requirements of the application. In the Global Double Layer DIN Rail Terminal Blocks Market, manufacturers offer products with both types of connections to cater to the diverse needs of their customers. The choice between spring-cage and screw connections often depends on factors such as the ease of installation, maintenance requirements, and the environmental conditions in which the terminal blocks will be used.

Power Industry, Metallurgy and Mining, Construction Industry, Other in the Global Double Layer DIN Rail Terminal Blocks Market:

The Global Double Layer DIN Rail Terminal Blocks Market finds extensive usage across various industries, including the power industry, metallurgy and mining, construction industry, and others. In the power industry, these terminal blocks are crucial for ensuring reliable and efficient power distribution. They are used in switchgear, control panels, and distribution boards to connect and manage electrical circuits. The double-layer design allows for more connections in a compact space, which is essential in power distribution systems where space is often limited. In the metallurgy and mining industries, the harsh operating conditions require robust and reliable electrical connections. Double layer DIN rail terminal blocks are used in control systems for machinery and equipment, providing secure connections that can withstand the vibrations and extreme temperatures commonly found in these environments. In the construction industry, these terminal blocks are used in building automation systems, lighting control, and HVAC systems. They provide a reliable and organized method for connecting various electrical components, ensuring the safety and efficiency of the electrical systems in buildings. Other industries that utilize double layer DIN rail terminal blocks include transportation, telecommunications, and manufacturing. In transportation, they are used in railway signaling systems and automotive control systems. In telecommunications, they are used in network equipment and data centers to manage and distribute electrical connections. In manufacturing, they are used in industrial automation systems, providing reliable connections for sensors, actuators, and control devices. The versatility and reliability of double layer DIN rail terminal blocks make them an essential component in a wide range of applications across various industries.

Global Double Layer DIN Rail Terminal Blocks Market Outlook:

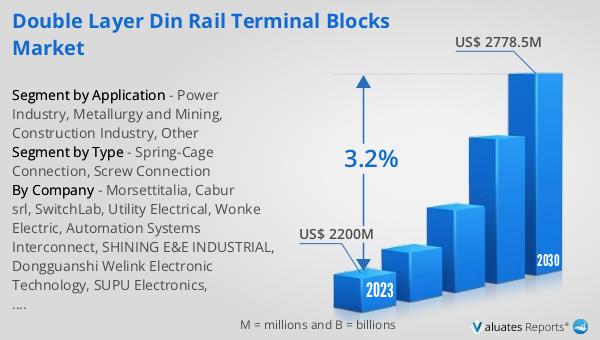

The global Double Layer DIN Rail Terminal Blocks market was valued at US$ 2200 million in 2023 and is anticipated to reach US$ 2778.5 million by 2030, witnessing a CAGR of 3.2% during the forecast period from 2024 to 2030. This market outlook indicates a steady growth trajectory for the industry, driven by the increasing demand for efficient and reliable electrical connections in various applications. The growth is attributed to the rising adoption of automation and control systems in industries such as power, metallurgy, mining, and construction. The double-layer design of these terminal blocks allows for more connections in a compact space, making them ideal for applications where space is limited. The market is also driven by the need for robust and reliable electrical connections in harsh operating conditions, such as those found in the metallurgy and mining industries. The versatility and reliability of double layer DIN rail terminal blocks make them an essential component in a wide range of applications, contributing to the steady growth of the market.

| Report Metric | Details |

| Report Name | Double Layer DIN Rail Terminal Blocks Market |

| Accounted market size in 2023 | US$ 2200 million |

| Forecasted market size in 2030 | US$ 2778.5 million |

| CAGR | 3.2% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Morsettitalia, Cabur srl, SwitchLab, Utility Electrical, Wonke Electric, Automation Systems Interconnect, SHINING E&E INDUSTRIAL, Dongguanshi Welink Electronic Technology, SUPU Electronics, Connectwell, MEAN WELL, Advice Electronics |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |