What is Global Magnesium Alloys for Consumer Electronics Market?

The Global Magnesium Alloys for Consumer Electronics Market is a rapidly evolving sector that focuses on the use of magnesium alloys in various consumer electronic devices. Magnesium alloys are lightweight, strong, and have excellent thermal conductivity, making them ideal for use in electronics that require durability and efficient heat dissipation. These alloys are increasingly being used in products such as laptops, smartphones, and cameras due to their ability to enhance performance while reducing weight. The market is driven by the growing demand for portable and high-performance electronic devices, as well as advancements in manufacturing technologies that make the production of magnesium alloy components more cost-effective. As consumer preferences shift towards more compact and efficient devices, the demand for magnesium alloys in this sector is expected to continue growing. The market also benefits from the increasing trend of miniaturization in electronics, where the lightweight and strong properties of magnesium alloys play a crucial role. Overall, the Global Magnesium Alloys for Consumer Electronics Market is poised for significant growth as it continues to meet the evolving needs of the consumer electronics industry.

Cast Alloys, Wrought Alloys, Others in the Global Magnesium Alloys for Consumer Electronics Market:

Magnesium alloys in the Global Magnesium Alloys for Consumer Electronics Market can be categorized into three main types: Cast Alloys, Wrought Alloys, and Others. Cast Alloys are produced by melting and casting magnesium into a desired shape. These alloys are known for their excellent castability, good mechanical properties, and low density, making them suitable for components that require complex shapes and high strength-to-weight ratios. They are commonly used in the production of laptop casings, camera bodies, and other electronic housings where intricate designs and lightweight properties are essential. Wrought Alloys, on the other hand, are processed through mechanical means such as rolling, extrusion, and forging. These alloys offer superior mechanical properties, including higher strength and better ductility compared to cast alloys. Wrought magnesium alloys are often used in applications that require high structural integrity and durability, such as internal components of smartphones and tablets. The "Others" category includes various specialized magnesium alloys that are tailored for specific applications in consumer electronics. These may include alloys with enhanced corrosion resistance, improved thermal properties, or specific mechanical characteristics required for niche applications. For instance, some specialized alloys are designed to withstand harsh environmental conditions, making them suitable for outdoor electronic devices. The versatility of magnesium alloys allows manufacturers to choose the most appropriate type based on the specific requirements of the electronic device, whether it be for structural components, heat dissipation, or aesthetic purposes. The continuous development and innovation in magnesium alloy compositions and processing techniques further expand their applicability in the consumer electronics market. As a result, magnesium alloys are becoming an integral part of the design and manufacturing process for a wide range of electronic devices, contributing to their performance, durability, and overall user experience.

Notebook, Cell Phone, Digital Camera, Other in the Global Magnesium Alloys for Consumer Electronics Market:

The usage of Global Magnesium Alloys for Consumer Electronics Market spans across various areas such as notebooks, cell phones, digital cameras, and other electronic devices. In notebooks, magnesium alloys are primarily used for the chassis and casing. The lightweight nature of magnesium alloys helps in reducing the overall weight of the notebook, making it more portable and user-friendly. Additionally, the excellent thermal conductivity of magnesium alloys aids in efficient heat dissipation, which is crucial for maintaining the performance and longevity of the device. In cell phones, magnesium alloys are used for both internal and external components. The strength and durability of these alloys provide robust protection for the delicate internal circuitry, while their lightweight properties contribute to the sleek and slim design of modern smartphones. Magnesium alloys also play a significant role in enhancing the thermal management of cell phones, preventing overheating during prolonged usage. Digital cameras benefit from magnesium alloys in several ways. The lightweight and strong properties of these alloys make them ideal for camera bodies, ensuring that the device is easy to handle while providing adequate protection for the sensitive internal components. The use of magnesium alloys also allows for more compact and ergonomic designs, enhancing the overall user experience. Other electronic devices, such as tablets, gaming consoles, and wearable technology, also utilize magnesium alloys for similar reasons. The versatility and performance benefits of magnesium alloys make them a preferred choice for manufacturers looking to improve the durability, efficiency, and aesthetics of their products. As consumer demand for high-performance, lightweight, and durable electronic devices continues to grow, the usage of magnesium alloys in these areas is expected to increase, driving further innovation and development in the Global Magnesium Alloys for Consumer Electronics Market.

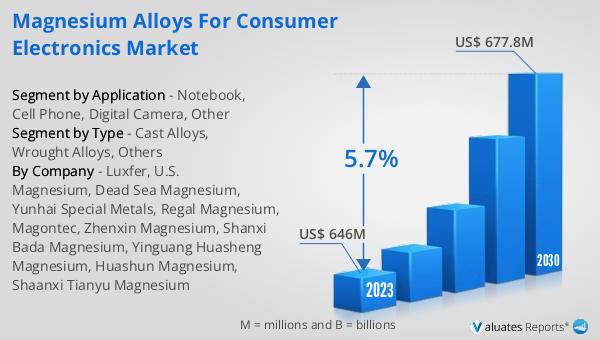

Global Magnesium Alloys for Consumer Electronics Market Outlook:

The global Magnesium Alloys for Consumer Electronics market was valued at US$ 646 million in 2023 and is anticipated to reach US$ 677.8 million by 2030, witnessing a CAGR of 5.7% during the forecast period 2024-2030. This market outlook highlights the steady growth trajectory of magnesium alloys in the consumer electronics sector. The increasing demand for lightweight, durable, and high-performance electronic devices is a significant driver for this market. Magnesium alloys offer a unique combination of properties that make them ideal for use in various consumer electronics, including laptops, smartphones, and cameras. The projected growth in market value reflects the ongoing advancements in manufacturing technologies and the continuous innovation in alloy compositions that enhance the performance and applicability of magnesium alloys. As manufacturers strive to meet the evolving needs of consumers, the adoption of magnesium alloys is expected to rise, contributing to the overall growth of the market. The forecasted CAGR of 5.7% indicates a robust and sustained demand for these materials, underscoring their importance in the future of consumer electronics. This positive market outlook suggests that magnesium alloys will continue to play a crucial role in the development of next-generation electronic devices, offering improved performance, durability, and user experience.

| Report Metric | Details |

| Report Name | Magnesium Alloys for Consumer Electronics Market |

| Accounted market size in 2023 | US$ 646 million |

| Forecasted market size in 2030 | US$ 677.8 million |

| CAGR | 5.7% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Luxfer, U.S. Magnesium, Dead Sea Magnesium, Yunhai Special Metals, Regal Magnesium, Magontec, Zhenxin Magnesium, Shanxi Bada Magnesium, Yinguang Huasheng Magnesium, Huashun Magnesium, Shaanxi Tianyu Magnesium |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |