What is Global Polyester Microfiber Market?

The Global Polyester Microfiber Market refers to the worldwide industry focused on the production, distribution, and utilization of polyester microfiber. Polyester microfiber is a synthetic fiber that is finer than one denier, which is about one-fifth the diameter of a human hair. This material is known for its softness, durability, and high absorbency, making it a popular choice in various applications. The market encompasses a wide range of products, including textiles, cleaning cloths, and leather substitutes. The demand for polyester microfiber is driven by its versatility and the growing awareness of its benefits over traditional materials. Industries such as home textiles, clothing, and automotive are significant consumers of polyester microfiber, contributing to the market's growth. The global reach of this market indicates its importance in both developed and developing economies, where it supports various sectors by providing high-quality, cost-effective alternatives to natural fibers. The continuous innovation and development in microfiber technology further enhance its applications, making it a crucial component in modern manufacturing and consumer goods.

Microfiber Leather, Microfiber Cleaning Cloths, Others in the Global Polyester Microfiber Market:

Microfiber leather, microfiber cleaning cloths, and other products are significant segments within the Global Polyester Microfiber Market. Microfiber leather is a synthetic alternative to genuine leather, made from a blend of polyester and polyurethane. It mimics the texture and appearance of real leather but offers superior durability, water resistance, and ease of maintenance. This makes it a preferred choice in the automotive, furniture, and fashion industries, where it is used for car seats, sofas, jackets, and bags. Microfiber cleaning cloths, on the other hand, are renowned for their exceptional cleaning capabilities. The ultra-fine fibers can trap dust, dirt, and bacteria more effectively than traditional cleaning materials, making them ideal for household cleaning, automotive detailing, and even in healthcare settings. These cloths are also reusable and machine washable, contributing to their popularity among environmentally conscious consumers. Other products in the polyester microfiber market include sportswear, bedding, and industrial filters. Sportswear made from microfiber offers excellent moisture-wicking properties, keeping athletes dry and comfortable. Bedding products, such as sheets and pillowcases, benefit from the softness and breathability of microfiber, enhancing sleep quality. Industrial filters made from microfiber are used in various applications, including air and water filtration, due to their fine particle retention capabilities. The versatility and performance of polyester microfiber products make them indispensable in numerous industries, driving the market's growth and innovation.

Home Textiles, Clothing, Daily Necessities, Other in the Global Polyester Microfiber Market:

The usage of polyester microfiber in home textiles, clothing, daily necessities, and other areas highlights its versatility and widespread appeal. In home textiles, polyester microfiber is used to make a variety of products, including bed sheets, pillowcases, curtains, and upholstery. Its softness, durability, and ease of care make it a popular choice for these applications. Microfiber bed sheets, for example, are known for their smooth texture and ability to wick away moisture, providing a comfortable sleeping experience. In clothing, polyester microfiber is used to produce sportswear, activewear, and casual wear. Its moisture-wicking properties and breathability make it ideal for garments that need to keep the wearer dry and comfortable during physical activities. Additionally, microfiber clothing is lightweight and quick-drying, making it convenient for everyday use. Daily necessities such as cleaning cloths, towels, and personal care products also benefit from the properties of polyester microfiber. Microfiber cleaning cloths are highly effective at trapping dust and dirt, making them a staple in households and commercial cleaning services. Towels made from microfiber are absorbent and quick-drying, making them ideal for use in bathrooms, kitchens, and gyms. Personal care products, such as makeup removal cloths and hair towels, leverage the gentle and absorbent nature of microfiber to provide effective and comfortable use. Other areas where polyester microfiber is used include automotive interiors, industrial applications, and healthcare. In automotive interiors, microfiber is used for seat covers, headliners, and cleaning cloths, providing a durable and easy-to-clean solution. Industrial applications include filtration systems, where microfiber's fine fibers can effectively capture particles and contaminants. In healthcare, microfiber is used for cleaning and disinfecting surfaces, as well as in medical textiles such as gowns and drapes. The diverse applications of polyester microfiber across various sectors underscore its importance and the ongoing demand for this versatile material.

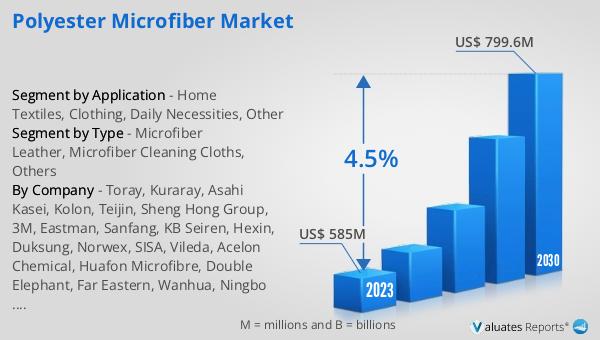

Global Polyester Microfiber Market Outlook:

The global Polyester Microfiber market was valued at US$ 585 million in 2023 and is anticipated to reach US$ 799.6 million by 2030, witnessing a CAGR of 4.5% during the forecast period 2024-2030. This growth trajectory reflects the increasing demand for polyester microfiber across various industries and applications. The market's expansion is driven by the material's unique properties, such as its softness, durability, and high absorbency, which make it suitable for a wide range of products. As consumers and industries continue to recognize the benefits of polyester microfiber over traditional materials, the market is expected to grow steadily. The projected growth also indicates the potential for innovation and development within the industry, as manufacturers seek to enhance the performance and applications of polyester microfiber. This positive outlook for the global Polyester Microfiber market underscores its significance in the modern economy and its role in supporting various sectors with high-quality, cost-effective solutions.

| Report Metric | Details |

| Report Name | Polyester Microfiber Market |

| Accounted market size in 2023 | US$ 585 million |

| Forecasted market size in 2030 | US$ 799.6 million |

| CAGR | 4.5% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Toray, Kuraray, Asahi Kasei, Kolon, Teijin, Sheng Hong Group, 3M, Eastman, Sanfang, KB Seiren, Hexin, Duksung, Norwex, SISA, Vileda, Acelon Chemical, Huafon Microfibre, Double Elephant, Far Eastern, Wanhua, Ningbo Green Textile, Tricol, Meisheng, Hengli |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |