What is Global Food Grade Polyethylene Glycol (PEG) Market?

The Global Food Grade Polyethylene Glycol (PEG) Market refers to the worldwide industry focused on the production and distribution of polyethylene glycol that meets food-grade standards. Polyethylene glycol (PEG) is a polyether compound that is widely used in various industries due to its versatility and safety. In the food industry, food-grade PEG is utilized as an additive to improve texture, moisture retention, and stability of food products. It is also used as a carrier for flavors and colors, and as a solvent for food additives. The market for food-grade PEG is driven by the increasing demand for processed and convenience foods, which require additives to maintain quality and extend shelf life. Additionally, the growing awareness of food safety and quality standards has led to a higher demand for food-grade PEG, as it is considered safe for consumption and complies with regulatory requirements. The market is characterized by the presence of several key players who are continuously investing in research and development to innovate and improve the quality of food-grade PEG. The global food-grade PEG market is expected to grow steadily, driven by the expanding food and beverage industry and the increasing adoption of food-grade additives.

Mw (<1000), Mw (1000-10000), Mw (10000-20000) in the Global Food Grade Polyethylene Glycol (PEG) Market:

In the Global Food Grade Polyethylene Glycol (PEG) Market, PEG is categorized based on its molecular weight (Mw), which significantly influences its properties and applications. PEG with a molecular weight of less than 1000 (Mw < 1000) is typically used in applications where low viscosity and high solubility are required. This type of PEG is often used as a humectant, solvent, and dispersing agent in various food products. It helps in maintaining moisture content and improving the texture of food items. PEG with a molecular weight between 1000 and 10000 (Mw 1000-10000) is more viscous and is used in applications where a thicker consistency is needed. This type of PEG is commonly used as a stabilizer, thickener, and emulsifier in food products. It helps in maintaining the stability and consistency of food items, preventing separation of ingredients, and improving the overall texture. PEG with a molecular weight between 10000 and 20000 (Mw 10000-20000) is even more viscous and is used in applications where a high degree of stability and viscosity is required. This type of PEG is often used as a binder, lubricant, and coating agent in food products. It helps in improving the texture, appearance, and shelf life of food items. The choice of PEG with different molecular weights depends on the specific requirements of the food product and the desired properties. Manufacturers in the food industry select the appropriate type of PEG based on its molecular weight to achieve the desired functionality and quality of the final product. The versatility of PEG with different molecular weights makes it a valuable additive in the food industry, catering to a wide range of applications and ensuring the quality and safety of food products.

Dairy, Beverage, Bakery, Savory, Others in the Global Food Grade Polyethylene Glycol (PEG) Market:

The usage of Global Food Grade Polyethylene Glycol (PEG) Market in various areas such as dairy, beverage, bakery, savory, and others is extensive and diverse. In the dairy industry, food-grade PEG is used as an emulsifier and stabilizer in products like ice cream, yogurt, and cheese. It helps in maintaining the smooth texture and consistency of these products, preventing the separation of ingredients, and improving their shelf life. In the beverage industry, PEG is used as a solubilizer and stabilizer in products like soft drinks, juices, and alcoholic beverages. It helps in maintaining the clarity and stability of these beverages, preventing the separation of ingredients, and enhancing their overall quality. In the bakery industry, PEG is used as a humectant and dough conditioner in products like bread, cakes, and pastries. It helps in maintaining the moisture content and texture of these products, preventing them from becoming dry and stale, and improving their shelf life. In the savory industry, PEG is used as a thickener and stabilizer in products like sauces, dressings, and soups. It helps in maintaining the consistency and stability of these products, preventing the separation of ingredients, and enhancing their overall quality. In other areas, food-grade PEG is used in a variety of applications such as confectionery, snacks, and processed foods. It helps in improving the texture, appearance, and shelf life of these products, ensuring their quality and safety. The versatility and functionality of food-grade PEG make it a valuable additive in the food industry, catering to a wide range of applications and ensuring the quality and safety of food products.

Global Food Grade Polyethylene Glycol (PEG) Market Outlook:

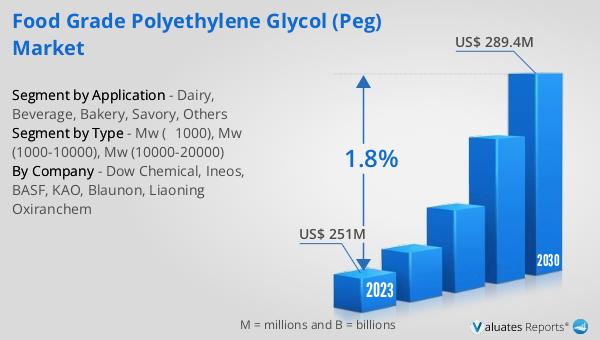

The global Food Grade Polyethylene Glycol (PEG) market was valued at US$ 251 million in 2023 and is anticipated to reach US$ 289.4 million by 2030, witnessing a CAGR of 1.8% during the forecast period 2024-2030. This indicates a steady growth in the market, driven by the increasing demand for food-grade additives in the food and beverage industry. The market is expected to grow at a compound annual growth rate (CAGR) of 1.8% during the forecast period, reflecting the rising adoption of food-grade PEG in various applications. The increasing demand for processed and convenience foods, coupled with the growing awareness of food safety and quality standards, is driving the growth of the food-grade PEG market. The market is characterized by the presence of several key players who are continuously investing in research and development to innovate and improve the quality of food-grade PEG. The steady growth of the market is also attributed to the expanding food and beverage industry, which requires additives to maintain the quality and extend the shelf life of food products. The global food-grade PEG market is expected to witness steady growth, driven by the increasing demand for food-grade additives and the expanding food and beverage industry.

| Report Metric | Details |

| Report Name | Food Grade Polyethylene Glycol (PEG) Market |

| Accounted market size in 2023 | US$ 251 million |

| Forecasted market size in 2030 | US$ 289.4 million |

| CAGR | 1.8% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Dow Chemical, Ineos, BASF, KAO, Blaunon, Liaoning Oxiranchem |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |