What is Global Mobile Hydrogen Liquefier Market?

The Global Mobile Hydrogen Liquefier Market is a rapidly evolving sector that focuses on the production and distribution of liquefied hydrogen using mobile units. These mobile hydrogen liquefiers are designed to convert gaseous hydrogen into its liquid form, which is easier to store and transport. The liquefaction process involves cooling hydrogen to extremely low temperatures, making it more energy-dense and efficient for various applications. This market is gaining traction due to the increasing demand for clean and sustainable energy solutions. Mobile hydrogen liquefiers offer flexibility and convenience, allowing hydrogen to be produced and delivered to remote locations or areas with limited infrastructure. This technology is particularly beneficial for industries and regions that require a reliable and portable hydrogen supply. The market is driven by advancements in hydrogen production technologies, government initiatives promoting hydrogen as a clean energy source, and the growing adoption of hydrogen fuel cells in various sectors. As the world moves towards a greener future, the Global Mobile Hydrogen Liquefier Market is expected to play a crucial role in the transition to a hydrogen-based economy.

Below 50kg/Day, Above 50kg/Day in the Global Mobile Hydrogen Liquefier Market:

In the Global Mobile Hydrogen Liquefier Market, the production capacity is often categorized based on the amount of hydrogen liquefied per day. Two primary categories are Below 50kg/Day and Above 50kg/Day. Mobile hydrogen liquefiers with a capacity of Below 50kg/Day are typically used for small-scale applications and pilot projects. These units are compact and can be easily transported to different locations, making them ideal for research and development purposes, as well as for supplying hydrogen to small businesses or remote areas with limited hydrogen demand. They are also used in niche markets where the hydrogen requirement is not very high but still essential for specific applications. On the other hand, mobile hydrogen liquefiers with a capacity of Above 50kg/Day are designed for larger-scale operations. These units are capable of producing significant quantities of liquefied hydrogen, making them suitable for industrial applications, large-scale hydrogen refueling stations, and regions with higher hydrogen demand. They are often used in conjunction with renewable energy sources, such as wind or solar power, to produce green hydrogen, which is then liquefied and distributed to various end-users. The ability to produce larger quantities of liquefied hydrogen also makes these units more cost-effective in the long run, as they can serve multiple customers and applications simultaneously. The choice between Below 50kg/Day and Above 50kg/Day mobile hydrogen liquefiers depends on several factors, including the specific needs of the end-users, the availability of hydrogen production infrastructure, and the overall demand for hydrogen in the target market. Both categories play a vital role in the growth and development of the Global Mobile Hydrogen Liquefier Market, catering to different segments and ensuring a steady supply of liquefied hydrogen for various applications.

Cars, Drones, Trucks, Vessel, Others in the Global Mobile Hydrogen Liquefier Market:

The Global Mobile Hydrogen Liquefier Market finds its usage in a wide range of applications, including cars, drones, trucks, vessels, and other areas. In the automotive sector, mobile hydrogen liquefiers are used to supply liquefied hydrogen to fuel cell vehicles (FCVs). These vehicles use hydrogen fuel cells to generate electricity, which powers the electric motor. The use of liquefied hydrogen in cars offers several advantages, such as longer driving ranges, faster refueling times, and reduced greenhouse gas emissions compared to traditional gasoline or diesel vehicles. In the drone industry, mobile hydrogen liquefiers provide a reliable and portable source of hydrogen for fuel cell-powered drones. These drones are used in various applications, including surveillance, agriculture, and delivery services. The use of liquefied hydrogen in drones allows for longer flight times and higher payload capacities, making them more efficient and versatile. In the trucking industry, mobile hydrogen liquefiers are used to supply hydrogen to fuel cell trucks. These trucks are designed for long-haul transportation and offer several benefits, such as reduced emissions, lower operating costs, and improved fuel efficiency. The use of liquefied hydrogen in trucks also helps to address the challenges of range anxiety and refueling infrastructure, as mobile hydrogen liquefiers can be deployed to remote locations or along major transportation routes. In the maritime sector, mobile hydrogen liquefiers are used to supply hydrogen to fuel cell-powered vessels. These vessels are used for various purposes, including passenger ferries, cargo ships, and research vessels. The use of liquefied hydrogen in vessels offers several advantages, such as reduced emissions, lower noise levels, and improved fuel efficiency. Finally, mobile hydrogen liquefiers are also used in other areas, such as backup power systems, industrial processes, and portable power generation. These applications benefit from the flexibility and convenience of mobile hydrogen liquefiers, which can be easily transported and deployed to different locations as needed. Overall, the Global Mobile Hydrogen Liquefier Market plays a crucial role in supporting the adoption of hydrogen fuel cells across various sectors, contributing to a cleaner and more sustainable energy future.

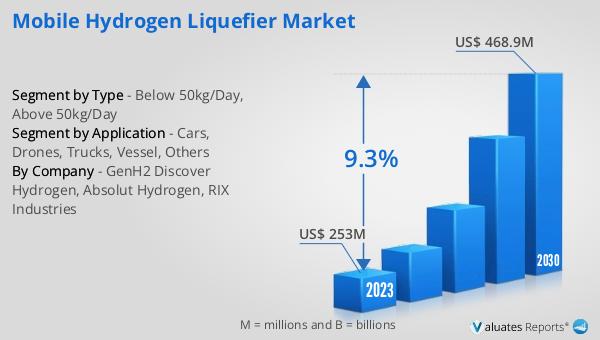

Global Mobile Hydrogen Liquefier Market Outlook:

The global Mobile Hydrogen Liquefier market was valued at US$ 253 million in 2023 and is anticipated to reach US$ 468.9 million by 2030, witnessing a CAGR of 9.3% during the forecast period 2024-2030. This significant growth reflects the increasing demand for mobile hydrogen liquefiers across various industries and applications. The market's expansion is driven by several factors, including advancements in hydrogen production technologies, government initiatives promoting hydrogen as a clean energy source, and the growing adoption of hydrogen fuel cells in sectors such as automotive, aerospace, and maritime. The ability of mobile hydrogen liquefiers to provide a flexible and portable solution for hydrogen production and distribution makes them an attractive option for both small-scale and large-scale applications. As the world continues to transition towards a hydrogen-based economy, the Global Mobile Hydrogen Liquefier Market is expected to play a vital role in meeting the growing demand for clean and sustainable energy solutions.

| Report Metric | Details |

| Report Name | Mobile Hydrogen Liquefier Market |

| Accounted market size in 2023 | US$ 253 million |

| Forecasted market size in 2030 | US$ 468.9 million |

| CAGR | 9.3% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | GenH2 Discover Hydrogen, Absolut Hydrogen, RIX Industries |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |