What is Global Plotter Printers Market?

The Global Plotter Printers Market refers to the worldwide industry that manufactures and sells plotter printers. Plotter printers are specialized devices used for printing vector graphics, which are images created using lines and curves rather than pixels. These printers are essential for producing large-scale graphics such as architectural blueprints, engineering designs, and detailed maps. The market encompasses various types of plotter printers, including inkjet, drum, and flatbed plotters, each catering to different needs and applications. The demand for plotter printers is driven by industries like construction, advertising, textile, and manufacturing, which require high-quality, large-format prints. As technology advances, the market continues to evolve, offering more efficient and versatile printing solutions to meet the growing needs of various sectors. The global plotter printers market is characterized by continuous innovation, competitive pricing, and a focus on sustainability, making it a dynamic and essential part of the printing industry.

Inkjet Plotter, Drum Plotter, Flatbed Plotter in the Global Plotter Printers Market:

Inkjet plotters, drum plotters, and flatbed plotters are three primary types of plotter printers that serve different functions within the Global Plotter Printers Market. Inkjet plotters are widely used due to their versatility and ability to produce high-quality prints with vibrant colors. They work by spraying tiny droplets of ink onto the paper, making them ideal for detailed graphics, posters, and photographic prints. Inkjet plotters are popular in industries such as advertising, graphic design, and photography, where precision and color accuracy are crucial. Drum plotters, on the other hand, use a rotating drum to move the paper while a pen or other marking device draws the image. These plotters are known for their accuracy and are often used in engineering and architectural fields for creating detailed technical drawings and blueprints. Drum plotters are less common today but still valued for their precision in specific applications. Flatbed plotters use a stationary flat surface on which the paper is placed, and the plotting head moves over the paper to create the image. These plotters are suitable for printing on various materials, including thick and rigid substrates, making them ideal for industrial applications and large-scale signage. Flatbed plotters are often used in the textile industry for printing patterns on fabrics and in the manufacturing sector for creating detailed parts and components. Each type of plotter printer has its unique advantages and is chosen based on the specific requirements of the task at hand. The diversity of plotter printers in the market ensures that there is a suitable solution for every printing need, from high-quality color graphics to precise technical drawings.

Posters and Signs, Advertising and Displays, Textile and Industrial Field, Others in the Global Plotter Printers Market:

The Global Plotter Printers Market finds extensive usage in various areas, including posters and signs, advertising and displays, the textile and industrial field, and others. In the realm of posters and signs, plotter printers are indispensable for creating large, eye-catching visuals that are used for promotional purposes, events, and informational displays. The ability to produce high-resolution, vibrant prints makes plotter printers ideal for this application, ensuring that the final product stands out and effectively communicates the intended message. In advertising and displays, plotter printers are used to create banners, billboards, and other large-format advertisements that require high-quality graphics and durability. The precision and color accuracy of plotter printers make them a preferred choice for advertisers looking to make a significant impact with their visual campaigns. In the textile and industrial field, plotter printers are used for printing patterns on fabrics, creating detailed designs for clothing, and producing industrial components with high precision. The versatility of plotter printers allows them to handle a wide range of materials, making them suitable for various industrial applications. Additionally, plotter printers are used in other areas such as education, where they are employed to create large-scale educational materials, and in the medical field for printing detailed anatomical charts and diagrams. The wide range of applications for plotter printers highlights their importance in various industries and underscores the need for continuous innovation and development in the Global Plotter Printers Market.

Global Plotter Printers Market Outlook:

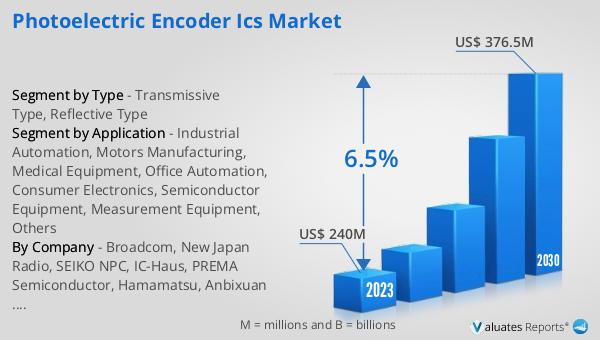

The global Plotter Printers market was valued at US$ 1359 million in 2023 and is anticipated to reach US$ 2232.5 million by 2030, witnessing a CAGR of 6.5% during the forecast period 2024-2030. This significant growth reflects the increasing demand for high-quality, large-format printing solutions across various industries. The market's expansion is driven by advancements in printing technology, the growing need for precise and vibrant prints, and the rising adoption of plotter printers in sectors such as construction, advertising, and textiles. As businesses and industries continue to seek efficient and reliable printing solutions, the plotter printers market is expected to experience sustained growth, offering new opportunities for innovation and development. The projected growth rate underscores the market's potential and the importance of plotter printers in meeting the evolving needs of modern industries.

| Report Metric | Details |

| Report Name | Plotter Printers Market |

| Accounted market size in 2023 | US$ 1359 million |

| Forecasted market size in 2030 | US$ 2232.5 million |

| CAGR | 6.5% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Consumption by Region |

|

| By Company | HP, Canon, Epson, Xerox, Ricoh, OKI, Roland, Mimaki Global, Mutoh, Durst, DGI |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |