What is Global High Frequency Induction Heating Devices Market?

The Global High Frequency Induction Heating Devices Market refers to the worldwide industry focused on the production, distribution, and utilization of high-frequency induction heating devices. These devices use electromagnetic induction to heat materials, primarily metals, without direct contact. The technology is highly efficient and precise, making it ideal for various industrial applications such as welding, brazing, heat treating, and metal hardening. The market encompasses a wide range of products, including induction heating machines, coils, and power supplies, catering to industries like automotive, aerospace, electronics, and manufacturing. The growth of this market is driven by the increasing demand for energy-efficient and environmentally friendly heating solutions, advancements in technology, and the expanding industrial sector. As industries continue to seek ways to improve production efficiency and reduce energy consumption, the adoption of high-frequency induction heating devices is expected to rise, contributing to the market's overall growth.

Direct Induction Heating, Indirect Induction Heating in the Global High Frequency Induction Heating Devices Market:

Direct induction heating and indirect induction heating are two primary methods utilized in the Global High Frequency Induction Heating Devices Market. Direct induction heating involves the direct application of electromagnetic fields to the material that needs to be heated. This method is highly efficient as it allows for rapid and localized heating, making it ideal for applications requiring precise temperature control. For instance, in the automotive industry, direct induction heating is used for hardening gears and other components, ensuring they meet stringent performance standards. The process involves placing the material within a coil, through which a high-frequency alternating current is passed. This generates an electromagnetic field that induces eddy currents within the material, causing it to heat up due to electrical resistance. The key advantage of direct induction heating is its ability to achieve high temperatures quickly and uniformly, which is crucial for processes like welding and brazing. On the other hand, indirect induction heating involves heating a secondary material, which then transfers the heat to the target material. This method is often used when direct heating is not feasible or when the material to be heated is non-conductive. In the semiconductor industry, for example, indirect induction heating is used to heat silicon wafers during the manufacturing process. The wafers are placed on a conductive susceptor, which is heated by the induction coil. The heat is then transferred from the susceptor to the wafers, ensuring uniform temperature distribution. Indirect induction heating is also used in applications where the material to be heated is sensitive to electromagnetic fields or where precise control over the heating process is required. One of the main benefits of indirect induction heating is its ability to provide consistent and controlled heating, which is essential for processes like annealing and tempering. Both direct and indirect induction heating methods have their unique advantages and are chosen based on the specific requirements of the application. The choice between the two methods depends on factors such as the material properties, desired heating rate, and the level of temperature control needed. In the Global High Frequency Induction Heating Devices Market, manufacturers offer a wide range of equipment designed to cater to both direct and indirect heating applications. These devices are equipped with advanced features such as programmable controls, real-time monitoring, and energy-efficient designs, making them suitable for various industrial processes. As industries continue to evolve and demand more efficient and precise heating solutions, the adoption of both direct and indirect induction heating methods is expected to grow, driving the overall market expansion.

Metallurgy Heat Treatment, Semiconductor Industry, Others in the Global High Frequency Induction Heating Devices Market:

The Global High Frequency Induction Heating Devices Market finds extensive usage in various industries, including metallurgy heat treatment, the semiconductor industry, and others. In metallurgy heat treatment, high-frequency induction heating devices are used for processes such as hardening, annealing, tempering, and brazing. These processes are essential for enhancing the mechanical properties of metals, such as hardness, strength, and wear resistance. For instance, in the automotive industry, induction heating is used to harden gears, crankshafts, and other critical components, ensuring they can withstand high stress and wear. The precise control offered by induction heating allows for uniform heating and cooling, resulting in consistent and high-quality metallurgical properties. Additionally, the energy efficiency and rapid heating capabilities of induction heating devices make them an attractive choice for large-scale heat treatment operations, reducing production time and costs. In the semiconductor industry, high-frequency induction heating devices play a crucial role in the manufacturing of semiconductor components. These devices are used for processes such as wafer heating, bonding, and annealing. For example, during the production of silicon wafers, induction heating is used to achieve the precise temperatures required for doping and diffusion processes. The ability to control the heating rate and temperature distribution accurately is vital for ensuring the quality and performance of semiconductor devices. Induction heating is also used in the bonding process, where it provides the necessary heat for attaching semiconductor chips to substrates. The non-contact nature of induction heating minimizes the risk of contamination and damage to delicate semiconductor materials, making it an ideal choice for the industry. As the demand for advanced electronic devices continues to grow, the semiconductor industry increasingly relies on high-frequency induction heating devices to meet stringent manufacturing standards. Beyond metallurgy and semiconductors, high-frequency induction heating devices are used in various other industries, including aerospace, medical, and food processing. In the aerospace industry, induction heating is used for applications such as brazing and welding of critical components, ensuring high strength and reliability. The medical industry utilizes induction heating for processes such as sterilization and the manufacturing of medical devices. For instance, induction heating is used to bond and shape medical implants, ensuring they meet precise specifications and biocompatibility standards. In the food processing industry, induction heating is used for applications such as sealing and pasteurization, providing efficient and uniform heating while maintaining product quality. The versatility and efficiency of high-frequency induction heating devices make them suitable for a wide range of applications, driving their adoption across various industries. As these industries continue to seek innovative and efficient heating solutions, the demand for high-frequency induction heating devices is expected to grow, contributing to the overall market expansion.

Global High Frequency Induction Heating Devices Market Outlook:

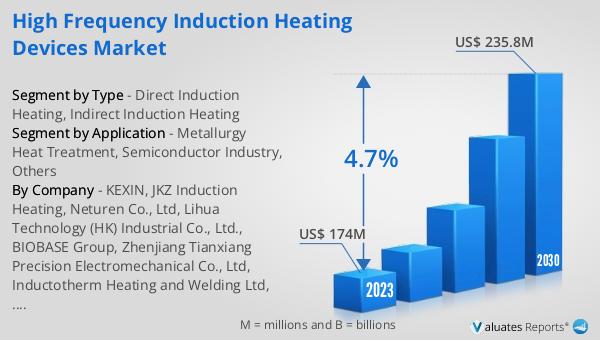

The global High Frequency Induction Heating Devices market was valued at US$ 174 million in 2023 and is anticipated to reach US$ 235.8 million by 2030, witnessing a CAGR of 4.7% during the forecast period 2024-2030. This market growth reflects the increasing demand for energy-efficient and precise heating solutions across various industries. High-frequency induction heating devices offer numerous advantages, including rapid heating, precise temperature control, and energy efficiency, making them an attractive choice for applications in metallurgy, semiconductors, aerospace, and more. As industries continue to evolve and seek ways to improve production efficiency and reduce energy consumption, the adoption of high-frequency induction heating devices is expected to rise. The market's expansion is also driven by technological advancements and the development of innovative products that cater to the specific needs of different industries. With the growing emphasis on sustainability and energy conservation, high-frequency induction heating devices are poised to play a crucial role in shaping the future of industrial heating solutions.

| Report Metric | Details |

| Report Name | High Frequency Induction Heating Devices Market |

| Accounted market size in 2023 | US$ 174 million |

| Forecasted market size in 2030 | US$ 235.8 million |

| CAGR | 4.7% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | KEXIN, JKZ Induction Heating, Neturen Co., Ltd, Lihua Technology (HK) Industrial Co., Ltd., BIOBASE Group, Zhenjiang Tianxiang Precision Electromechanical Co., Ltd, Inductotherm Heating and Welding Ltd, Lepel Corporation, Abhay Induction Tech Pvt. Ltd., Zhengzhou Ketchan Electronic Co.,Ltd, Fuji Electronics Industry Co., Ltd., Green Power, SEHYANG IND CO., LTD., MAGNETOTHERM, Dai-ichi Kiden Co.,Ltd |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |