What is Global Shuttle Container Market?

The Global Shuttle Container Market refers to the industry that deals with the production, distribution, and utilization of shuttle containers. Shuttle containers are specialized containers designed for efficient and secure transportation of goods over short to medium distances. These containers are often used in logistics and supply chain operations to streamline the movement of products between different points, such as warehouses, distribution centers, and retail outlets. The market encompasses various types of shuttle containers, including those made from different materials like steel, aluminum, and composite materials, each offering unique benefits in terms of durability, weight, and cost. The global shuttle container market is driven by the increasing demand for efficient and cost-effective transportation solutions, the growth of e-commerce, and the need for improved supply chain management. Companies operating in this market are continuously innovating to develop containers that are more durable, lightweight, and environmentally friendly. The market is also influenced by regulatory standards and technological advancements that aim to enhance the safety and efficiency of container transportation.

All-in-one, Split Type in the Global Shuttle Container Market:

In the Global Shuttle Container Market, there are primarily two types of containers: All-in-one and Split Type. All-in-one shuttle containers are designed as a single, integrated unit that combines multiple functionalities into one container. These containers are highly versatile and can be used for a wide range of applications, from transporting perishable goods to handling hazardous materials. The all-in-one design ensures that the container is robust and can withstand various environmental conditions, making it ideal for long-distance transportation. On the other hand, Split Type shuttle containers consist of separate components that can be assembled and disassembled as needed. This modular approach offers greater flexibility and customization options, allowing users to adapt the container to specific requirements. Split Type containers are particularly useful in situations where space is limited or where the container needs to be frequently reconfigured. Both types of containers have their own advantages and are chosen based on the specific needs of the transportation and logistics operations. The choice between All-in-one and Split Type containers often depends on factors such as the nature of the goods being transported, the distance of transportation, and the specific requirements of the supply chain. Companies in the Global Shuttle Container Market are continually innovating to improve the design and functionality of both All-in-one and Split Type containers, ensuring that they meet the evolving needs of the industry.

Airport, Transportation in the Global Shuttle Container Market:

The usage of shuttle containers in airports and transportation is a critical aspect of the Global Shuttle Container Market. In airports, shuttle containers play a vital role in the efficient handling and transportation of luggage, cargo, and other goods. These containers are designed to be easily loaded and unloaded, ensuring that the movement of goods is swift and seamless. The use of shuttle containers in airports helps in reducing the turnaround time for flights, thereby improving overall operational efficiency. Additionally, these containers are built to withstand the rigors of air transportation, ensuring that the contents remain secure and intact. In the broader transportation sector, shuttle containers are used extensively for the movement of goods across various modes of transport, including road, rail, and sea. The versatility of shuttle containers makes them an ideal choice for intermodal transportation, where goods need to be transferred between different types of transport without the need for repacking. This not only saves time but also reduces the risk of damage to the goods. The use of shuttle containers in transportation also contributes to cost savings, as they can be reused multiple times and are designed to maximize the use of available space. Furthermore, shuttle containers are often equipped with tracking and monitoring systems, allowing for real-time visibility of the goods during transit. This enhances the security and reliability of the transportation process, ensuring that goods are delivered on time and in good condition. Overall, the use of shuttle containers in airports and transportation is a key driver of efficiency and cost-effectiveness in the logistics and supply chain industry.

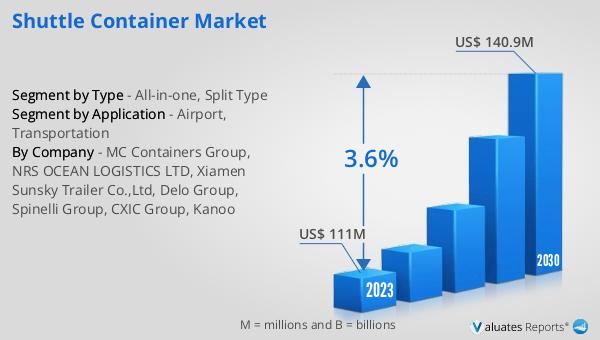

Global Shuttle Container Market Outlook:

The global Shuttle Container market was valued at US$ 111 million in 2023 and is anticipated to reach US$ 140.9 million by 2030, witnessing a CAGR of 3.6% during the forecast period 2024-2030. This market outlook indicates a steady growth trajectory for the shuttle container industry, driven by increasing demand for efficient and reliable transportation solutions. The projected growth reflects the expanding applications of shuttle containers across various sectors, including logistics, e-commerce, and manufacturing. As companies continue to seek ways to optimize their supply chain operations, the adoption of shuttle containers is expected to rise. The market's growth is also supported by technological advancements that enhance the functionality and durability of shuttle containers, making them more suitable for a wide range of transportation needs. Additionally, the emphasis on sustainability and environmental responsibility is likely to drive the development of eco-friendly shuttle containers, further boosting market growth. Overall, the global Shuttle Container market is poised for significant expansion, offering numerous opportunities for innovation and investment in the coming years.

| Report Metric | Details |

| Report Name | Shuttle Container Market |

| Accounted market size in 2023 | US$ 111 million |

| Forecasted market size in 2030 | US$ 140.9 million |

| CAGR | 3.6% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | MC Containers Group, NRS OCEAN LOGISTICS LTD, Xiamen Sunsky Trailer Co.,Ltd, Delo Group, Spinelli Group, CXIC Group, Kanoo |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |