What is Global In-Floor Scissor Lift Market?

The Global In-Floor Scissor Lift Market refers to the industry that manufactures and sells scissor lifts designed to be installed directly into the floor. These lifts are primarily used to raise and lower heavy loads in various settings, such as automotive repair shops, manufacturing plants, and warehouses. Unlike traditional scissor lifts that are mobile and can be moved around, in-floor scissor lifts are fixed in one location, providing a stable and permanent lifting solution. They are particularly useful in environments where space is limited, as they can be recessed into the floor when not in use, thus not obstructing the workspace. The market for these lifts is driven by the need for efficient and safe lifting solutions in industries that handle heavy materials or equipment. Technological advancements and the increasing focus on workplace safety are also contributing to the growth of this market.

Fixed, Move in the Global In-Floor Scissor Lift Market:

In the Global In-Floor Scissor Lift Market, there are two main types of lifts: fixed and moveable. Fixed in-floor scissor lifts are permanently installed in one location and are designed to provide a stable and reliable lifting solution. These lifts are ideal for environments where the lifting needs are consistent and do not require frequent changes in location. For example, in automotive repair shops, fixed in-floor scissor lifts are used to raise vehicles for maintenance and repairs. The fixed nature of these lifts ensures that they are always ready for use and do not need to be moved around, which can save time and increase efficiency. On the other hand, moveable in-floor scissor lifts offer more flexibility as they can be relocated to different areas within a facility. These lifts are designed with mobility in mind and often come with features such as wheels or tracks that allow them to be easily moved. Moveable in-floor scissor lifts are particularly useful in environments where the lifting needs vary and require the lift to be used in different locations. For instance, in a large warehouse, a moveable in-floor scissor lift can be used to lift heavy pallets in one area and then be moved to another area to perform a similar task. Both fixed and moveable in-floor scissor lifts have their own advantages and are chosen based on the specific needs of the facility. The choice between fixed and moveable lifts depends on factors such as the layout of the facility, the types of materials being handled, and the frequency of lifting tasks. In some cases, a combination of both fixed and moveable lifts may be used to provide a comprehensive lifting solution. The Global In-Floor Scissor Lift Market continues to evolve with advancements in technology and increasing demand for efficient and safe lifting solutions. Manufacturers are constantly innovating to improve the performance and safety features of these lifts, making them more versatile and user-friendly. As industries continue to seek ways to improve productivity and safety, the demand for both fixed and moveable in-floor scissor lifts is expected to grow.

Building, Logistic, Others in the Global In-Floor Scissor Lift Market:

The Global In-Floor Scissor Lift Market finds extensive usage in various areas, including building, logistics, and others. In the building sector, in-floor scissor lifts are commonly used for tasks such as lifting construction materials, tools, and equipment to different levels of a building. These lifts provide a stable and reliable solution for moving heavy loads, which can significantly improve the efficiency of construction projects. By being recessed into the floor, these lifts do not obstruct the workspace when not in use, allowing for a more organized and safer working environment. In the logistics sector, in-floor scissor lifts play a crucial role in the handling and transportation of goods. They are used in warehouses and distribution centers to lift and lower pallets, crates, and other heavy items. The ability to integrate these lifts into the floor allows for seamless and efficient movement of goods, reducing the risk of accidents and improving overall productivity. In-floor scissor lifts can also be used in loading docks to facilitate the loading and unloading of trucks, making the process faster and more efficient. Apart from building and logistics, in-floor scissor lifts are also used in various other industries such as manufacturing, automotive, and retail. In manufacturing plants, these lifts are used to move heavy machinery and equipment, as well as to assist in assembly line operations. In the automotive industry, in-floor scissor lifts are used in repair shops and service centers to lift vehicles for maintenance and repairs. In the retail sector, these lifts can be used in warehouses and storage areas to handle heavy inventory items. The versatility and efficiency of in-floor scissor lifts make them a valuable asset in any industry that requires the lifting and handling of heavy loads. The increasing focus on workplace safety and the need for efficient material handling solutions are driving the demand for in-floor scissor lifts across various sectors. As industries continue to seek ways to improve productivity and safety, the usage of in-floor scissor lifts is expected to grow.

Global In-Floor Scissor Lift Market Outlook:

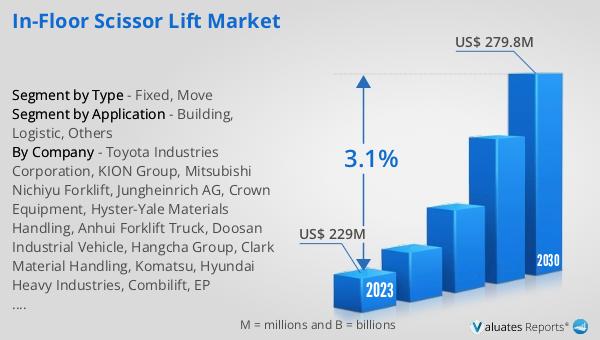

The global In-Floor Scissor Lift market was valued at US$ 229 million in 2023 and is anticipated to reach US$ 279.8 million by 2030, witnessing a CAGR of 3.1% during the forecast period 2024-2030. This market outlook indicates a steady growth trajectory for the in-floor scissor lift industry over the next few years. The increasing demand for efficient and safe lifting solutions in various industries is a key factor driving this growth. As more industries recognize the benefits of in-floor scissor lifts, such as improved productivity and enhanced workplace safety, the market is expected to expand further. Technological advancements and innovations in lift design are also contributing to the market's growth, making these lifts more versatile and user-friendly. The steady growth rate of 3.1% CAGR reflects the ongoing need for reliable and efficient lifting solutions in industries such as construction, logistics, manufacturing, and automotive. As the market continues to evolve, manufacturers are likely to focus on developing new features and improving the performance of in-floor scissor lifts to meet the changing needs of their customers. Overall, the global In-Floor Scissor Lift market is poised for significant growth in the coming years, driven by the increasing demand for safe and efficient lifting solutions across various sectors.

| Report Metric | Details |

| Report Name | In-Floor Scissor Lift Market |

| Accounted market size in 2023 | US$ 229 million |

| Forecasted market size in 2030 | US$ 279.8 million |

| CAGR | 3.1% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Toyota Industries Corporation, KION Group, Mitsubishi Nichiyu Forklift, Jungheinrich AG, Crown Equipment, Hyster-Yale Materials Handling, Anhui Forklift Truck, Doosan Industrial Vehicle, Hangcha Group, Clark Material Handling, Komatsu, Hyundai Heavy Industries, Combilift, EP Equipment, Konecranes, Shandong SeTAQ Instruments Co, Ltd., Rotary Lift, BendPak, Challenger Lifts, Hofmann Lifts, Forward Lift |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |