What is Global Physician Credentialing Services Market?

The Global Physician Credentialing Services Market is a specialized sector that focuses on verifying and validating the qualifications, experience, and professional background of physicians and other healthcare providers. This process ensures that healthcare professionals meet the necessary standards and regulations to provide medical services. Credentialing involves a thorough review of a physician's education, training, residency, licenses, certifications, and work history. It is a critical component in maintaining the quality and safety of healthcare services, as it helps to prevent unqualified individuals from practicing medicine. The market for these services is growing due to the increasing complexity of healthcare regulations, the need for compliance with insurance and governmental requirements, and the rising demand for high-quality healthcare services globally. Companies in this market offer a range of services, including primary source verification, background checks, and ongoing monitoring of credentials to ensure continuous compliance. The Global Physician Credentialing Services Market plays a vital role in the healthcare industry by ensuring that only qualified and competent professionals are allowed to practice, thereby safeguarding patient safety and enhancing the overall quality of care.

Individual Physician Credentialing, CAQH Database, Insurance Panel Applications, Comprehensive Outsourcing Services in the Global Physician Credentialing Services Market:

Individual Physician Credentialing is a meticulous process that involves verifying a physician's qualifications, including their education, training, and professional experience. This process is essential for ensuring that healthcare providers meet the necessary standards to deliver safe and effective care. The CAQH (Council for Affordable Quality Healthcare) Database is a centralized repository that stores credentialing information for healthcare providers. It simplifies the credentialing process by allowing providers to submit their information once and share it with multiple organizations. Insurance Panel Applications are another critical aspect of physician credentialing. These applications are submitted to insurance companies to become an in-network provider, which allows physicians to offer services to patients covered by those insurers. Comprehensive Outsourcing Services in the Global Physician Credentialing Services Market involve third-party companies managing the entire credentialing process on behalf of healthcare providers. These services include primary source verification, background checks, and ongoing monitoring of credentials to ensure continuous compliance with regulatory requirements. Outsourcing these services can save healthcare organizations time and resources, allowing them to focus on patient care. The Global Physician Credentialing Services Market is essential for maintaining the quality and safety of healthcare services by ensuring that only qualified and competent professionals are allowed to practice.

Enterprise, Individual in the Global Physician Credentialing Services Market:

The usage of Global Physician Credentialing Services Market can be seen in both enterprise and individual settings. For enterprises, such as hospitals, clinics, and healthcare organizations, credentialing services are crucial for maintaining compliance with regulatory standards and ensuring the quality of care provided to patients. These organizations often manage large numbers of healthcare providers and need to ensure that all staff members meet the necessary qualifications and standards. Credentialing services help enterprises streamline the verification process, reduce administrative burdens, and mitigate risks associated with hiring unqualified providers. For individual healthcare providers, credentialing services are equally important. Physicians, nurses, and other healthcare professionals need to have their credentials verified to practice legally and to be eligible for insurance reimbursements. Credentialing services help individuals navigate the complex process of submitting their qualifications to various regulatory bodies and insurance companies. By ensuring that their credentials are up-to-date and compliant with industry standards, individual providers can focus on delivering high-quality care to their patients. The Global Physician Credentialing Services Market plays a vital role in both enterprise and individual settings by ensuring that healthcare providers meet the necessary standards and regulations to deliver safe and effective care.

Global Physician Credentialing Services Market Outlook:

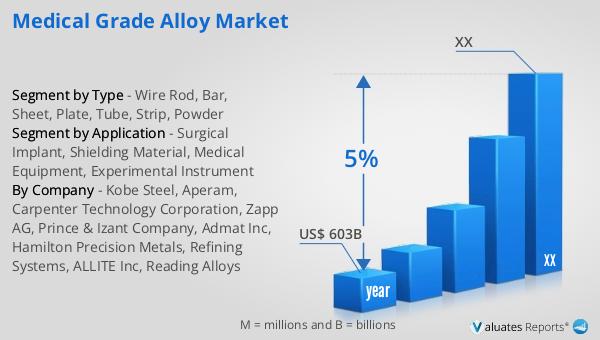

According to our research, the global market for medical devices is estimated at US$ 603 billion in the year 2023 and will be growing at a CAGR of 5% during the next six years. This significant market size reflects the increasing demand for advanced medical technologies and innovations in healthcare. The growth rate indicates a steady expansion of the market, driven by factors such as the aging population, rising prevalence of chronic diseases, and advancements in medical technology. The medical devices market encompasses a wide range of products, including diagnostic equipment, surgical instruments, and monitoring devices, all of which play a crucial role in modern healthcare. The projected growth of this market highlights the ongoing need for investment in research and development to bring new and improved medical devices to market. As the healthcare industry continues to evolve, the demand for innovative medical devices is expected to rise, contributing to the overall growth of the market. The Global Physician Credentialing Services Market is closely linked to the medical devices market, as both sectors are essential for ensuring the quality and safety of healthcare services.

| Report Metric | Details |

| Report Name | Physician Credentialing Services Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Microwize Technology, iRCM, Synergy HCLS, Synergyhcls, Ninety Nine Healthcare Management, e-care India, Rush Credentialing, Business Integrity Services, Flatworld Solutions, True North Physician Agency |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |