What is Global Rotary Vane Pumps for Medical Market?

The Global Rotary Vane Pumps for Medical Market refers to the worldwide industry focused on the production and distribution of rotary vane pumps specifically designed for medical applications. These pumps are essential components in various medical devices and systems, providing reliable and efficient vacuum and pressure solutions. Rotary vane pumps operate by using a series of vanes mounted on a rotor that rotates inside a cavity, creating a vacuum or pressure as the vanes move. In the medical field, these pumps are used in applications such as laboratory equipment, diagnostic devices, and therapeutic machines. The market for these pumps is driven by the increasing demand for advanced medical technologies, the growing prevalence of chronic diseases, and the need for precise and reliable medical equipment. As healthcare systems worldwide continue to evolve and expand, the demand for high-quality rotary vane pumps is expected to rise, making this market a critical component of the global medical device industry.

Single-stage Rotary Vane Pumps for Medical, Two-stages Rotary Vane Pumps for Medical in the Global Rotary Vane Pumps for Medical Market:

Single-stage rotary vane pumps for medical applications are designed to provide a reliable and efficient vacuum solution with a single set of vanes and a single rotor. These pumps are typically used in applications where a moderate level of vacuum is required, such as in laboratory equipment, medical suction devices, and certain diagnostic machines. Single-stage pumps are known for their simplicity, ease of maintenance, and cost-effectiveness, making them a popular choice for many medical applications. They operate by using a single rotor with vanes that slide in and out of slots, creating a vacuum as the rotor turns. This design allows for a continuous and steady vacuum, which is essential for many medical procedures and processes. On the other hand, two-stage rotary vane pumps are designed to provide a higher level of vacuum by using two sets of vanes and rotors in a series configuration. This design allows for a more efficient and deeper vacuum, making them suitable for more demanding medical applications such as in surgical suction systems, vacuum-assisted wound closure devices, and certain types of diagnostic equipment that require a higher level of vacuum. Two-stage pumps are known for their superior performance, durability, and ability to maintain a consistent vacuum over extended periods. They operate by using the first stage to create an initial vacuum, which is then further enhanced by the second stage, resulting in a deeper and more stable vacuum. Both single-stage and two-stage rotary vane pumps play a crucial role in the medical field, providing the necessary vacuum and pressure solutions for a wide range of medical devices and systems. The choice between single-stage and two-stage pumps depends on the specific requirements of the application, with single-stage pumps being more suitable for less demanding applications and two-stage pumps being ideal for more critical and high-performance applications. As the global medical device market continues to grow, the demand for both types of rotary vane pumps is expected to increase, driven by the need for advanced and reliable medical equipment.

Laboratory, Medical in the Global Rotary Vane Pumps for Medical Market:

The usage of global rotary vane pumps in the medical market spans various areas, including laboratories and medical facilities. In laboratory settings, rotary vane pumps are essential for creating the necessary vacuum conditions for various experiments and processes. They are used in applications such as vacuum filtration, degassing of liquids, and vacuum drying. These pumps provide a reliable and consistent vacuum, which is crucial for maintaining the integrity and accuracy of laboratory experiments. In addition, rotary vane pumps are used in laboratory equipment such as mass spectrometers, gas chromatographs, and electron microscopes, where a stable vacuum is required for optimal performance. In medical facilities, rotary vane pumps are used in a wide range of applications, including surgical suction systems, vacuum-assisted wound closure devices, and respiratory therapy equipment. In surgical settings, these pumps provide the necessary vacuum for suctioning fluids and debris during procedures, ensuring a clear and clean surgical field. In wound care, rotary vane pumps are used in vacuum-assisted closure devices, which help promote healing by creating a controlled vacuum environment around the wound. In respiratory therapy, these pumps are used in devices such as ventilators and continuous positive airway pressure (CPAP) machines, providing the necessary pressure and vacuum for effective treatment. The versatility and reliability of rotary vane pumps make them an essential component in both laboratory and medical settings, contributing to the overall efficiency and effectiveness of medical procedures and processes. As the demand for advanced medical technologies continues to grow, the usage of rotary vane pumps in these areas is expected to increase, further driving the growth of the global rotary vane pumps for the medical market.

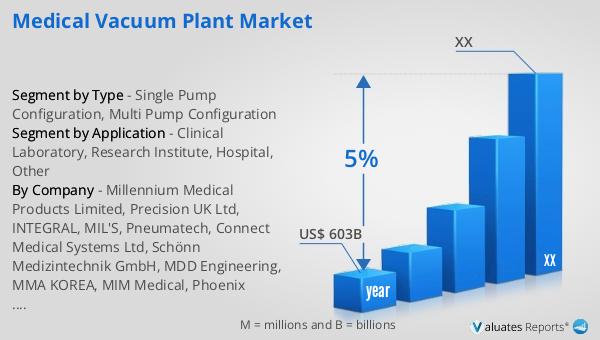

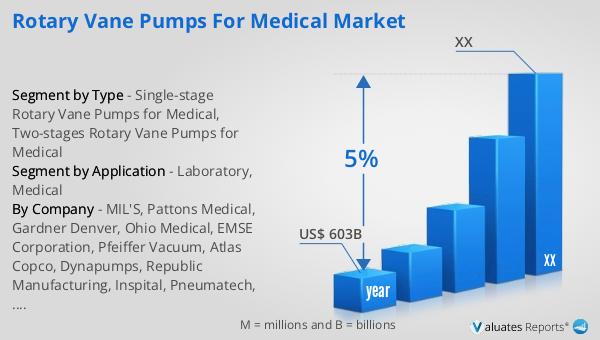

Global Rotary Vane Pumps for Medical Market Outlook:

Based on our research, the global market for medical devices is projected to reach approximately $603 billion by the year 2023, with an anticipated growth rate of 5% annually over the next six years. This significant market size underscores the critical role that medical devices play in modern healthcare systems worldwide. The steady growth rate reflects the increasing demand for advanced medical technologies, driven by factors such as the aging global population, the rising prevalence of chronic diseases, and the continuous advancements in medical research and development. As healthcare providers strive to improve patient outcomes and enhance the efficiency of medical procedures, the need for reliable and innovative medical devices, including rotary vane pumps, is more important than ever. This growth trajectory highlights the opportunities for manufacturers and suppliers in the medical device industry to expand their product offerings and meet the evolving needs of healthcare professionals and patients. The global rotary vane pumps for the medical market is poised to benefit from this overall market expansion, as these pumps are integral components in various medical devices and systems. By providing reliable vacuum and pressure solutions, rotary vane pumps contribute to the functionality and performance of critical medical equipment, supporting the delivery of high-quality healthcare services.

| Report Metric | Details |

| Report Name | Rotary Vane Pumps for Medical Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| Segment by Type |

|

| Segment by Application |

|

| Consumption by Region |

|

| By Company | MIL'S, Pattons Medical, Gardner Denver, Ohio Medical, EMSE Corporation, Pfeiffer Vacuum, Atlas Copco, Dynapumps, Republic Manufacturing, Inspital, Pneumatech, BeiJing Cape Golden Gas System Company LTD, KYKY TECHNOLOGY CO., LTD, Lingchi Jidian |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |