What is MEMS Optical Accelerometers - Global Market?

MEMS Optical Accelerometers are tiny devices that measure acceleration using micro-electromechanical systems (MEMS) technology. These accelerometers are crucial in various applications, including automotive, consumer electronics, and industrial sectors. The global market for MEMS Optical Accelerometers is growing due to the increasing demand for precise and reliable motion detection. These devices are known for their high sensitivity, low power consumption, and compact size, making them ideal for integration into various systems. The market is driven by advancements in technology, increasing adoption in emerging applications, and the need for enhanced performance in existing applications. As industries continue to innovate and integrate more sophisticated technologies, the demand for MEMS Optical Accelerometers is expected to rise, contributing to the overall growth of the market.

Multi-Axis, Single-Axis in the MEMS Optical Accelerometers - Global Market:

MEMS Optical Accelerometers can be categorized into Multi-Axis and Single-Axis types. Multi-Axis accelerometers measure acceleration in multiple directions, typically along three axes: X, Y, and Z. These accelerometers are essential in applications requiring comprehensive motion detection and analysis, such as in smartphones, gaming controllers, and advanced robotics. They provide a more detailed understanding of movement, which is crucial for applications that rely on precise motion tracking and control. On the other hand, Single-Axis accelerometers measure acceleration along a single direction. These are often used in applications where motion detection is required in a specific direction, such as in automotive airbag systems, industrial machinery, and certain medical devices. Single-Axis accelerometers are simpler and often more cost-effective than their Multi-Axis counterparts, making them suitable for applications with less complex motion detection needs. Both types of accelerometers leverage MEMS technology to achieve high performance, reliability, and miniaturization. The choice between Multi-Axis and Single-Axis accelerometers depends on the specific requirements of the application, including the level of motion complexity, cost considerations, and integration needs. As technology continues to advance, the capabilities of both Multi-Axis and Single-Axis MEMS Optical Accelerometers are expected to improve, further expanding their range of applications and driving market growth.

Fiber Optical Communication System, Test Equipment in the MEMS Optical Accelerometers - Global Market:

MEMS Optical Accelerometers are widely used in Fiber Optical Communication Systems and Test Equipment due to their precision and reliability. In Fiber Optical Communication Systems, these accelerometers play a crucial role in maintaining the stability and performance of the communication network. They help in monitoring and compensating for any vibrations or movements that could affect the alignment of the optical fibers, ensuring a stable and high-quality signal transmission. This is particularly important in long-distance communication networks where even minor disruptions can lead to significant signal degradation. In Test Equipment, MEMS Optical Accelerometers are used to measure and analyze vibrations and movements in various testing scenarios. They provide accurate and reliable data, which is essential for the development and testing of new products and technologies. For example, in the automotive industry, these accelerometers are used in crash testing to measure the impact forces and analyze the performance of safety systems. In the aerospace industry, they are used to test the stability and performance of aircraft components under different conditions. The high sensitivity and precision of MEMS Optical Accelerometers make them ideal for these applications, ensuring accurate and reliable results. As the demand for advanced communication systems and high-performance test equipment continues to grow, the usage of MEMS Optical Accelerometers in these areas is expected to increase, driving the overall market growth.

MEMS Optical Accelerometers - Global Market Outlook:

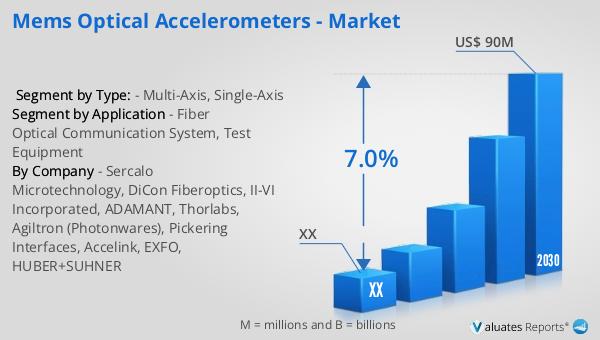

The global market for MEMS Optical Accelerometers was valued at approximately US$ 55 million in 2023. Projections indicate that this market will expand to an adjusted size of around US$ 90 million by 2030, reflecting a compound annual growth rate (CAGR) of 7.0% during the forecast period from 2024 to 2030. The Asia-Pacific region is identified as the fastest-growing market for these devices. This growth can be attributed to the increasing adoption of advanced technologies and the rising demand for precise motion detection in various applications across the region. The rapid industrialization and technological advancements in countries like China, Japan, and South Korea are driving the demand for MEMS Optical Accelerometers. Additionally, the growing consumer electronics market in the Asia-Pacific region is contributing to the increased adoption of these devices. As industries continue to innovate and integrate more sophisticated technologies, the demand for MEMS Optical Accelerometers is expected to rise, contributing to the overall growth of the market.

| Report Metric | Details |

| Report Name | MEMS Optical Accelerometers - Market |

| Forecasted market size in 2030 | US$ 90 million |

| CAGR | 7.0% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Sercalo Microtechnology, DiCon Fiberoptics, II-VI Incorporated, ADAMANT, Thorlabs, Agiltron (Photonwares), Pickering Interfaces, Accelink, EXFO, HUBER+SUHNER |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |