What is Metal Powder Additive Manufacturing Equipment - Global Market?

Metal Powder Additive Manufacturing Equipment refers to advanced machinery used in the process of creating three-dimensional objects from metal powders. This technology, also known as 3D printing, involves the layer-by-layer addition of metal powder to build complex structures that are difficult or impossible to achieve with traditional manufacturing methods. The global market for this equipment is expanding rapidly due to its applications in various industries such as automotive, aerospace, healthcare, and academia. The equipment includes various types of machines that utilize different techniques to fuse metal powders into solid objects. The increasing demand for lightweight, durable, and complex metal parts is driving the growth of this market. Additionally, advancements in technology and the reduction in production costs are making metal powder additive manufacturing more accessible to a broader range of industries. This market is poised for significant growth as more industries recognize the benefits of this innovative manufacturing process.

Selective Laser Melting (SLM), Electron Beam Melting (EBM), Others in the Metal Powder Additive Manufacturing Equipment - Global Market:

Selective Laser Melting (SLM) is a prominent technique in the Metal Powder Additive Manufacturing Equipment market. SLM uses a high-powered laser to selectively melt and fuse metal powder particles together, layer by layer, to create a solid object. This method is highly precise and allows for the creation of intricate geometries and complex structures that are difficult to achieve with traditional manufacturing methods. SLM is widely used in industries such as aerospace and healthcare, where precision and material properties are critical. Electron Beam Melting (EBM) is another key technique in this market. EBM uses an electron beam to melt and fuse metal powder particles. This method operates in a vacuum environment, which reduces the risk of contamination and allows for the production of high-purity metal parts. EBM is particularly suitable for manufacturing parts that require high strength and durability, such as turbine blades and orthopedic implants. Other techniques in the Metal Powder Additive Manufacturing Equipment market include Binder Jetting and Directed Energy Deposition (DED). Binder Jetting involves the use of a liquid binding agent to fuse metal powder particles together, followed by a sintering process to create a solid object. This method is known for its high production speed and is often used for creating large, complex parts. Directed Energy Deposition (DED) uses a focused energy source, such as a laser or electron beam, to melt and deposit metal powder onto a substrate. This technique is highly versatile and can be used for repairing existing parts or creating new ones from scratch. Each of these techniques has its own advantages and limitations, and the choice of method depends on the specific requirements of the application. The Metal Powder Additive Manufacturing Equipment market is characterized by continuous innovation and development, with new techniques and materials being introduced regularly. This dynamic environment is driving the adoption of metal powder additive manufacturing across various industries, as companies seek to leverage the benefits of this advanced technology to improve their products and processes.

Automotive Industry, Aerospace Industry, Healthcare and Dental Industry, Academic Institutions, Others in the Metal Powder Additive Manufacturing Equipment - Global Market:

The usage of Metal Powder Additive Manufacturing Equipment spans across several key industries, each benefiting from the unique capabilities of this technology. In the automotive industry, metal powder additive manufacturing is used to produce lightweight and high-strength components, such as engine parts, exhaust systems, and structural components. This technology allows for the creation of complex geometries that improve the performance and efficiency of vehicles. Additionally, it enables rapid prototyping and customization, allowing automotive manufacturers to quickly iterate and optimize their designs. In the aerospace industry, metal powder additive manufacturing is used to produce critical components such as turbine blades, fuel nozzles, and structural parts. The ability to create lightweight and durable parts with complex geometries is particularly valuable in this industry, where weight reduction and performance optimization are crucial. This technology also allows for the production of parts with reduced lead times and lower costs compared to traditional manufacturing methods. In the healthcare and dental industry, metal powder additive manufacturing is used to produce customized implants, prosthetics, and surgical instruments. The ability to create patient-specific devices with high precision and biocompatibility is a significant advantage in this field. This technology also enables the production of complex structures, such as porous implants, that promote better integration with the human body. Academic institutions are also leveraging metal powder additive manufacturing for research and development purposes. This technology allows researchers to explore new materials, design innovative structures, and develop advanced manufacturing processes. It also provides students with hands-on experience in cutting-edge manufacturing techniques, preparing them for careers in various industries. Other industries, such as consumer goods, energy, and defense, are also adopting metal powder additive manufacturing to improve their products and processes. The versatility and capabilities of this technology make it a valuable tool for innovation and efficiency across a wide range of applications.

Metal Powder Additive Manufacturing Equipment - Global Market Outlook:

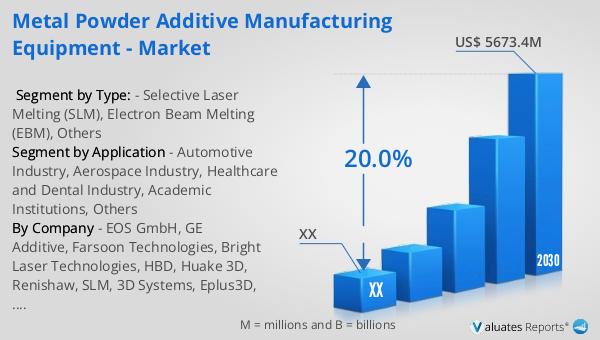

The global market for Metal Powder Additive Manufacturing Equipment was estimated to be worth US$ 1700 million in 2023 and is forecast to a readjusted size of US$ 5673.4 million by 2030 with a CAGR of 20.0% during the forecast period 2024-2030. Asia-Pacific is the fastest growing market. This significant growth is driven by the increasing adoption of metal powder additive manufacturing across various industries, including automotive, aerospace, healthcare, and academia. The ability to produce complex geometries, lightweight structures, and customized components is driving the demand for this technology. Additionally, advancements in technology and the reduction in production costs are making metal powder additive manufacturing more accessible to a broader range of industries. The Asia-Pacific region, in particular, is experiencing rapid growth due to the increasing investments in advanced manufacturing technologies and the presence of a large number of manufacturing industries. The region's strong economic growth and supportive government policies are also contributing to the expansion of the metal powder additive manufacturing market. As more industries recognize the benefits of this innovative manufacturing process, the global market for Metal Powder Additive Manufacturing Equipment is expected to continue its upward trajectory.

| Report Metric | Details |

| Report Name | Metal Powder Additive Manufacturing Equipment - Market |

| Forecasted market size in 2030 | US$ 5673.4 million |

| CAGR | 20.0% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | EOS GmbH, GE Additive, Farsoon Technologies, Bright Laser Technologies, HBD, Huake 3D, Renishaw, SLM, 3D Systems, Eplus3D, Exone, Xinjinghe |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |