What is Global Vacant Gelatin Capsules Market?

The Global Vacant Gelatin Capsules Market refers to the worldwide industry involved in the production and distribution of empty gelatin capsules. These capsules are primarily used in the pharmaceutical and nutraceutical industries to encapsulate various types of medications and dietary supplements. Gelatin capsules are favored for their ease of use, ability to mask the taste of the contents, and their ability to dissolve quickly in the stomach, ensuring rapid release of the encapsulated substance. The market encompasses a wide range of capsule sizes, colors, and compositions, including both hard and soft gelatin capsules. The demand for these capsules is driven by the growing pharmaceutical industry, increasing health awareness among consumers, and the rising popularity of dietary supplements. Additionally, advancements in capsule manufacturing technologies and the development of new gelatin formulations are contributing to the market's growth. The global reach of this market means that it is influenced by various regional regulations, consumer preferences, and economic conditions, making it a dynamic and complex industry.

Gastric Soluble, Enteric in the Global Vacant Gelatin Capsules Market:

Gastric soluble and enteric capsules are two types of gelatin capsules that serve different purposes in the Global Vacant Gelatin Capsules Market. Gastric soluble capsules are designed to dissolve quickly in the stomach, releasing their contents for immediate absorption. These capsules are typically used for medications that need to act fast or for substances that are best absorbed in the acidic environment of the stomach. On the other hand, enteric capsules are coated with a special material that prevents them from dissolving in the stomach. Instead, they pass through the stomach intact and dissolve in the more neutral pH environment of the intestines. This delayed release is beneficial for medications that can be irritating to the stomach lining or for substances that are better absorbed in the intestines. The choice between gastric soluble and enteric capsules depends on the specific needs of the medication or supplement being encapsulated. For instance, some medications for conditions like acid reflux or ulcers might be better suited for enteric capsules to avoid aggravating the stomach lining. Similarly, certain probiotics and enzymes are more effective when they reach the intestines, making enteric capsules the preferred choice. The manufacturing process for these capsules involves precise control over the materials and conditions to ensure the desired dissolution properties. This includes selecting the appropriate type of gelatin, adding specific coatings, and conducting rigorous quality control tests. The demand for both types of capsules is influenced by the growing pharmaceutical and nutraceutical industries, as well as increasing consumer awareness about the benefits of targeted drug delivery. Additionally, advancements in capsule technology, such as the development of new coating materials and improved manufacturing techniques, are driving innovation in this market. The global nature of the market means that manufacturers must navigate various regulatory requirements and consumer preferences, which can vary significantly from one region to another. Overall, the distinction between gastric soluble and enteric capsules highlights the importance of tailored solutions in the Global Vacant Gelatin Capsules Market, ensuring that medications and supplements are delivered in the most effective and safe manner possible.

Pharmacy, Hospital, Clinic in the Global Vacant Gelatin Capsules Market:

The usage of vacant gelatin capsules in pharmacies, hospitals, and clinics is widespread and multifaceted, reflecting the versatility and importance of these capsules in the healthcare industry. In pharmacies, vacant gelatin capsules are often used to compound personalized medications. Pharmacists can fill these capsules with specific dosages of medications tailored to individual patient needs, which is particularly useful for patients with unique medical conditions or those who require customized treatment plans. This practice, known as compounding, allows for greater flexibility in medication management and can improve patient compliance by providing medications in a more palatable form. In hospitals, vacant gelatin capsules play a crucial role in the administration of medications to patients. They are used to encapsulate a wide range of drugs, from pain relievers and antibiotics to vitamins and supplements. The use of gelatin capsules helps ensure accurate dosing and can make it easier for patients to swallow medications, which is especially important for those who have difficulty taking pills. Additionally, the rapid dissolution of gelatin capsules in the stomach allows for quick absorption of the medication, which can be critical in acute care settings where timely treatment is essential. Clinics also utilize vacant gelatin capsules for similar purposes, often in the context of outpatient care. Patients visiting clinics for routine check-ups or minor medical procedures may be prescribed medications that are dispensed in gelatin capsules. This can include everything from routine antibiotics to specialized treatments for chronic conditions. The use of gelatin capsules in clinics helps streamline the medication dispensing process and ensures that patients receive their prescribed treatments in a convenient and effective form. Overall, the use of vacant gelatin capsules in pharmacies, hospitals, and clinics underscores their importance in modern healthcare. These capsules provide a reliable and efficient means of delivering medications, enhancing patient compliance, and ensuring accurate dosing. Their versatility and ease of use make them an indispensable tool in the healthcare industry, contributing to better patient outcomes and improved overall health.

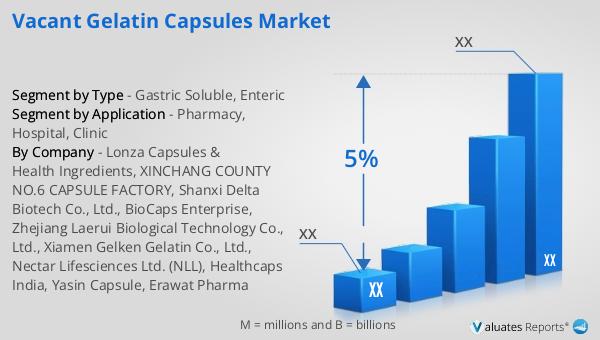

Global Vacant Gelatin Capsules Market Outlook:

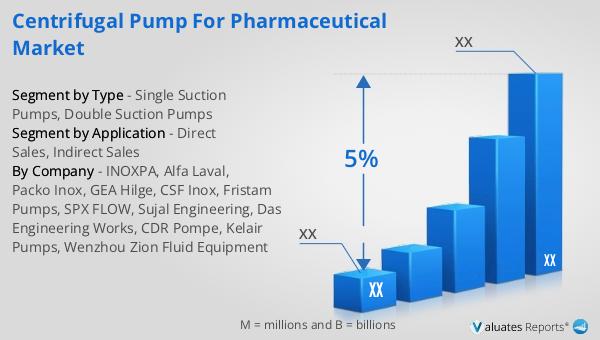

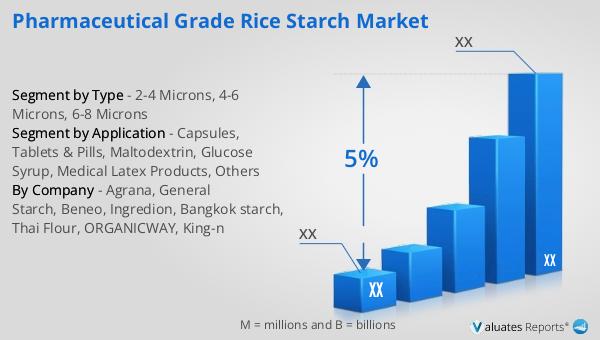

The global pharmaceutical market was valued at approximately 1475 billion USD in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5% over the next six years. In comparison, the chemical drug market has shown significant growth, increasing from 1005 billion USD in 2018 to an estimated 1094 billion USD in 2022. This growth reflects the expanding demand for pharmaceutical products and the continuous advancements in drug development and manufacturing. The increase in market value also highlights the importance of innovation and investment in the pharmaceutical industry, as companies strive to meet the evolving needs of patients and healthcare providers. The rising prevalence of chronic diseases, an aging population, and increasing healthcare expenditure are some of the key factors driving this growth. Additionally, the development of new therapies and the expansion of healthcare access in emerging markets are contributing to the overall expansion of the pharmaceutical and chemical drug markets. This positive market outlook underscores the critical role of the pharmaceutical industry in improving global health and well-being.

| Report Metric | Details |

| Report Name | Vacant Gelatin Capsules Market |

| CAGR | 5% |

| Segment by Type |

|

| Segment by Application |

|

| Consumption by Region |

|

| By Company | Lonza Capsules & Health Ingredients, XINCHANG COUNTY NO.6 CAPSULE FACTORY, Shanxi Delta Biotech Co., Ltd., BioCaps Enterprise, Zhejiang Laerui Biological Technology Co., Ltd., Xiamen Gelken Gelatin Co., Ltd., Nectar Lifesciences Ltd. (NLL), Healthcaps India, Yasin Capsule, Erawat Pharma |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |