What is Global Centrifugal Pump for Pharmaceutical Market?

The Global Centrifugal Pump for Pharmaceutical Market is a specialized segment within the broader pharmaceutical industry that focuses on the use of centrifugal pumps in various pharmaceutical processes. Centrifugal pumps are mechanical devices designed to move fluids by converting rotational kinetic energy to hydrodynamic energy. In the pharmaceutical sector, these pumps are crucial for tasks such as transferring liquids, maintaining fluid flow, and ensuring the consistency and purity of pharmaceutical products. The market for these pumps is driven by the increasing demand for efficient and reliable fluid handling systems in pharmaceutical manufacturing. Factors such as stringent regulatory requirements, the need for contamination-free processes, and the growing complexity of pharmaceutical formulations contribute to the rising adoption of centrifugal pumps. These pumps are designed to meet the specific needs of the pharmaceutical industry, including compliance with Good Manufacturing Practices (GMP) and the ability to handle a wide range of fluids, from viscous solutions to delicate suspensions. The global market for centrifugal pumps in the pharmaceutical sector is characterized by continuous innovation, with manufacturers focusing on developing pumps that offer higher efficiency, reduced energy consumption, and enhanced durability.

Single Suction Pumps, Double Suction Pumps in the Global Centrifugal Pump for Pharmaceutical Market:

Single Suction Pumps and Double Suction Pumps are two primary types of centrifugal pumps used in the pharmaceutical industry, each with distinct features and applications. Single Suction Pumps, also known as end-suction pumps, have a single inlet through which the fluid enters the impeller. These pumps are typically used for applications requiring moderate flow rates and pressures. They are known for their simplicity, ease of maintenance, and cost-effectiveness. Single Suction Pumps are often employed in processes such as water circulation, chemical transfer, and general fluid handling in pharmaceutical manufacturing. Their compact design makes them suitable for installations where space is limited. On the other hand, Double Suction Pumps, also referred to as split-case pumps, have two inlets that allow the fluid to enter the impeller from both sides. This design provides a balanced hydraulic load, resulting in higher efficiency and reduced axial thrust. Double Suction Pumps are ideal for high-flow applications and are commonly used in large-scale pharmaceutical production facilities. They are preferred for processes that require continuous and reliable fluid transfer, such as cooling water circulation, solvent recovery, and bulk liquid handling. The robust construction of Double Suction Pumps ensures long-term performance and minimal downtime, making them a valuable asset in demanding pharmaceutical environments. Both Single Suction and Double Suction Pumps play a crucial role in maintaining the efficiency and reliability of pharmaceutical processes. The choice between the two types depends on factors such as the specific application requirements, flow rate, pressure, and space constraints. Manufacturers of centrifugal pumps for the pharmaceutical market continuously innovate to enhance the performance, energy efficiency, and durability of these pumps, ensuring they meet the evolving needs of the industry.

Direct Sales, Indirect Sales in the Global Centrifugal Pump for Pharmaceutical Market:

The usage of Global Centrifugal Pumps in the Pharmaceutical Market can be categorized into Direct Sales and Indirect Sales channels. Direct Sales involve the direct interaction between the pump manufacturers and the end-users, such as pharmaceutical companies and contract manufacturing organizations. This sales channel allows manufacturers to offer customized solutions tailored to the specific needs of their clients. Direct Sales provide several advantages, including better control over the sales process, direct feedback from customers, and the ability to build long-term relationships. Manufacturers can offer comprehensive after-sales services, including installation, maintenance, and technical support, ensuring optimal performance and customer satisfaction. Direct Sales are particularly beneficial for large pharmaceutical companies that require specialized pumps for their complex manufacturing processes. On the other hand, Indirect Sales involve the use of intermediaries such as distributors, agents, and resellers to reach the end-users. This sales channel is advantageous for manufacturers looking to expand their market reach and penetrate new geographical regions. Indirect Sales allow manufacturers to leverage the established networks and market knowledge of intermediaries, reducing the time and cost associated with market entry. Distributors and agents play a crucial role in promoting the products, providing local support, and handling logistics. Indirect Sales are often preferred by small and medium-sized pharmaceutical companies that may not have the resources to engage directly with pump manufacturers. Both Direct and Indirect Sales channels are essential for the growth and success of the Global Centrifugal Pump for Pharmaceutical Market. Manufacturers must strategically balance their sales efforts across both channels to maximize market penetration and customer satisfaction.

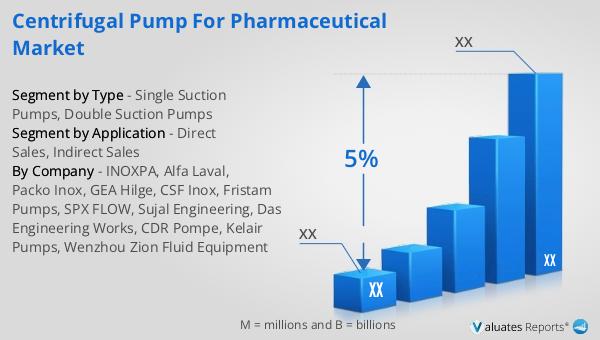

Global Centrifugal Pump for Pharmaceutical Market Outlook:

The global pharmaceutical market was valued at 1475 billion USD in 2022, experiencing a steady growth rate with a Compound Annual Growth Rate (CAGR) of 5% projected over the next six years. In comparison, the chemical drug market has shown significant growth, increasing from 1005 billion USD in 2018 to 1094 billion USD in 2022. This growth in the pharmaceutical sector underscores the rising demand for advanced and efficient manufacturing processes, including the use of centrifugal pumps. The increasing complexity of pharmaceutical formulations and the need for contamination-free processes drive the adoption of specialized centrifugal pumps designed to meet stringent regulatory requirements. As the pharmaceutical market continues to expand, the demand for reliable and efficient fluid handling systems, such as centrifugal pumps, is expected to grow, further fueling the market's development. The continuous innovation and technological advancements in pump design and manufacturing will play a crucial role in meeting the evolving needs of the pharmaceutical industry, ensuring the production of high-quality and safe pharmaceutical products.

| Report Metric | Details |

| Report Name | Centrifugal Pump for Pharmaceutical Market |

| CAGR | 5% |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | INOXPA, Alfa Laval, Packo Inox, GEA Hilge, CSF Inox, Fristam Pumps, SPX FLOW, Sujal Engineering, Das Engineering Works, CDR Pompe, Kelair Pumps, Wenzhou Zion Fluid Equipment |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |