What is Global Parylene Dimer Market?

The Global Parylene Dimer Market refers to the worldwide industry focused on the production, distribution, and application of parylene dimers. Parylene is a unique polymer that is applied as a thin film coating in various industries due to its excellent protective properties. The market encompasses various types of parylene, including Parylene N, Parylene C, Parylene D, Parylene F, and Parylene HT, each offering distinct characteristics suitable for different applications. These coatings are highly valued for their ability to provide a moisture barrier, electrical insulation, and chemical resistance, making them indispensable in sectors such as electronics, medical devices, automotive, and aerospace. The global demand for parylene dimers is driven by the increasing need for high-performance coatings that can enhance the durability and reliability of products in harsh environments. As industries continue to innovate and develop more advanced technologies, the role of parylene coatings becomes even more critical, ensuring the longevity and functionality of various components and devices. The market is characterized by continuous research and development efforts aimed at improving the properties of parylene coatings and expanding their applications across different sectors.

Parylene N, Parylene C, Parylene D, Parylene F, Parylene HT, Others in the Global Parylene Dimer Market:

Parylene N, Parylene C, Parylene D, Parylene F, and Parylene HT are different types of parylene used in the Global Parylene Dimer Market, each with unique properties and applications. Parylene N is the basic form of parylene, known for its excellent dielectric properties and high thermal stability. It is often used in applications where electrical insulation is critical. Parylene C, on the other hand, is widely used due to its superior moisture and chemical resistance. It is commonly applied in the medical field for coating surgical instruments and implants, as well as in the electronics industry for protecting circuit boards and components. Parylene D offers enhanced thermal stability compared to Parylene C, making it suitable for applications that require exposure to higher temperatures. Parylene F is known for its low dielectric constant and high thermal stability, making it ideal for advanced electronic applications. Parylene HT, the latest addition to the parylene family, offers the highest thermal stability and UV resistance, making it suitable for extreme environmental conditions. Each type of parylene is synthesized through a vapor deposition process, ensuring a uniform and pinhole-free coating. The choice of parylene type depends on the specific requirements of the application, such as the need for moisture resistance, thermal stability, or electrical insulation. The versatility of parylene coatings makes them suitable for a wide range of industries, including electronics, medical devices, automotive, aerospace, and more. As the demand for high-performance coatings continues to grow, the Global Parylene Dimer Market is expected to expand, driven by the need for reliable and durable protective coatings.

Military and Aerospace, Electronics, Medical, Automotive, Others in the Global Parylene Dimer Market:

The Global Parylene Dimer Market finds extensive usage in various sectors, including Military and Aerospace, Electronics, Medical, Automotive, and others. In the Military and Aerospace sector, parylene coatings are used to protect sensitive electronic components from harsh environmental conditions, such as extreme temperatures, humidity, and chemical exposure. These coatings ensure the reliability and longevity of critical systems, such as avionics, sensors, and communication devices. In the Electronics industry, parylene is widely used to coat printed circuit boards (PCBs), connectors, and other components, providing excellent moisture and chemical resistance, as well as electrical insulation. This helps in enhancing the performance and durability of electronic devices, especially in high-reliability applications. In the Medical field, parylene coatings are applied to surgical instruments, catheters, stents, and implants to provide a biocompatible and protective barrier. These coatings help in preventing corrosion, reducing friction, and ensuring the safety and efficacy of medical devices. In the Automotive industry, parylene is used to protect electronic components, sensors, and connectors from harsh environmental conditions, such as moisture, chemicals, and temperature fluctuations. This helps in improving the reliability and lifespan of automotive electronics. Other applications of parylene coatings include the protection of LED lights, MEMS devices, and various industrial components. The versatility and superior protective properties of parylene make it an ideal choice for a wide range of applications, ensuring the longevity and reliability of products in various industries.

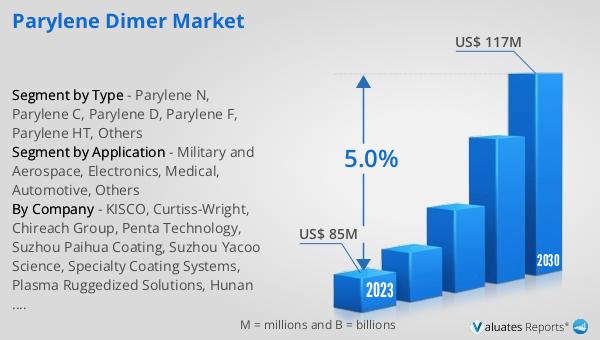

Global Parylene Dimer Market Outlook:

The global Parylene Dimer market, valued at US$ 85 million in 2023, is projected to grow to US$ 117 million by 2030, reflecting a compound annual growth rate (CAGR) of 5.0% during the forecast period from 2024 to 2030. This growth is driven by the increasing demand for high-performance coatings across various industries, including electronics, medical, automotive, and aerospace. Parylene coatings are highly valued for their excellent protective properties, such as moisture resistance, chemical resistance, and electrical insulation, making them indispensable in harsh environments. The continuous innovation and development of advanced technologies in these industries further fuel the demand for reliable and durable protective coatings. As a result, the Global Parylene Dimer Market is expected to witness significant growth, with manufacturers focusing on enhancing the properties of parylene coatings and expanding their applications across different sectors. The market outlook indicates a positive trend, with increasing investments in research and development, as well as the adoption of parylene coatings in emerging applications. This growth trajectory highlights the critical role of parylene coatings in ensuring the longevity and functionality of various components and devices, thereby driving the overall market expansion.

| Report Metric | Details |

| Report Name | Parylene Dimer Market |

| Accounted market size in 2023 | US$ 85 million |

| Forecasted market size in 2030 | US$ 117 million |

| CAGR | 5.0% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | KISCO, Curtiss-Wright, Chireach Group, Penta Technology, Suzhou Paihua Coating, Suzhou Yacoo Science, Specialty Coating Systems, Plasma Ruggedized Solutions, Hunan Solar Chemical |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |