What is Global Piston Rod Seal Market?

The Global Piston Rod Seal Market is a specialized segment within the broader industrial seals market. Piston rod seals are critical components used in hydraulic and pneumatic systems to prevent fluid leakage and ensure efficient operation. These seals are typically found in machinery and equipment that require precise control of fluid power, such as hydraulic cylinders, pneumatic actuators, and various types of industrial machinery. The market for piston rod seals is driven by the demand for high-performance sealing solutions that can withstand extreme pressures, temperatures, and environmental conditions. Industries such as automotive, construction, aerospace, and manufacturing heavily rely on these seals to maintain the integrity and performance of their equipment. The global market for piston rod seals is characterized by a diverse range of materials, designs, and applications, catering to the specific needs of different industries and operating conditions. As industries continue to advance and seek more efficient and reliable solutions, the demand for high-quality piston rod seals is expected to grow, driving innovation and development within this market segment.

Polyurethane, Rubber, Others in the Global Piston Rod Seal Market:

Polyurethane, rubber, and other materials play a significant role in the Global Piston Rod Seal Market, each offering unique properties and advantages. Polyurethane seals are known for their excellent wear resistance, high tensile strength, and flexibility, making them ideal for applications that require durability and long service life. These seals can withstand high pressures and are resistant to various chemicals, oils, and solvents, making them suitable for demanding environments. Rubber seals, on the other hand, are valued for their elasticity, resilience, and ability to maintain a tight seal under varying temperatures and pressures. They are commonly used in applications where flexibility and adaptability are crucial, such as in automotive and hydraulic systems. Rubber seals can be made from different types of rubber, including nitrile, silicone, and fluorocarbon, each offering specific benefits depending on the application requirements. Other materials used in piston rod seals include PTFE (polytetrafluoroethylene), which is known for its low friction and high chemical resistance, and thermoplastic elastomers, which combine the properties of rubber and plastic to offer a versatile sealing solution. These materials are often chosen for specialized applications where traditional materials may not perform adequately. The choice of material for piston rod seals depends on various factors, including the operating environment, pressure, temperature, and the type of fluid being sealed. Manufacturers in the Global Piston Rod Seal Market continuously innovate and develop new materials and designs to meet the evolving needs of different industries. This ongoing development ensures that piston rod seals can provide reliable performance and extend the lifespan of machinery and equipment, ultimately contributing to the efficiency and productivity of industrial operations.

Hydraulic Industry, Construction Machinery, Automotive, Others in the Global Piston Rod Seal Market:

The usage of piston rod seals in the Global Piston Rod Seal Market spans several key industries, including the hydraulic industry, construction machinery, automotive, and others. In the hydraulic industry, piston rod seals are essential for maintaining the integrity of hydraulic systems, which are used in a wide range of applications, from industrial machinery to mobile equipment. These seals prevent fluid leakage, ensuring that hydraulic systems operate efficiently and reliably. In construction machinery, piston rod seals are used in equipment such as excavators, loaders, and cranes, where they help maintain the performance and safety of hydraulic cylinders and actuators. The demanding conditions of construction sites require seals that can withstand heavy loads, high pressures, and harsh environmental conditions. In the automotive industry, piston rod seals are used in various components, including shock absorbers, power steering systems, and braking systems. These seals ensure that automotive systems operate smoothly and safely, contributing to the overall performance and reliability of vehicles. Other industries that utilize piston rod seals include aerospace, manufacturing, and marine, where they are used in applications that require precise control of fluid power and reliable sealing solutions. The versatility and importance of piston rod seals in these industries highlight their critical role in maintaining the efficiency and performance of machinery and equipment. As industries continue to evolve and demand more advanced and reliable solutions, the usage of piston rod seals is expected to grow, driving further innovation and development within the Global Piston Rod Seal Market.

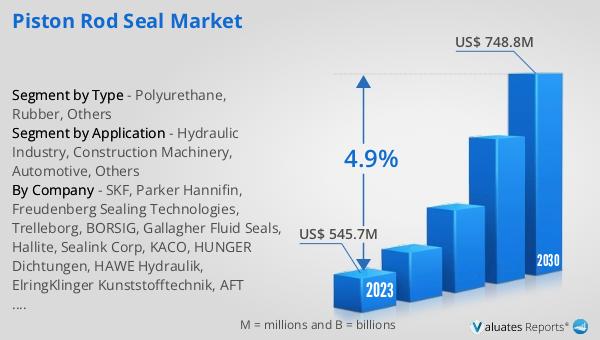

Global Piston Rod Seal Market Outlook:

The global Piston Rod Seal market was valued at US$ 545.7 million in 2023 and is anticipated to reach US$ 748.8 million by 2030, witnessing a CAGR of 4.9% during the forecast period 2024-2030. This market outlook indicates a steady growth trajectory for piston rod seals, driven by increasing demand across various industries. The projected growth reflects the ongoing need for high-performance sealing solutions that can enhance the efficiency and reliability of hydraulic and pneumatic systems. As industries such as automotive, construction, and manufacturing continue to advance, the demand for durable and efficient piston rod seals is expected to rise. The market's growth is also supported by continuous innovation in materials and designs, which aim to meet the evolving needs of different applications and operating conditions. The anticipated increase in market value underscores the importance of piston rod seals in maintaining the performance and longevity of machinery and equipment. This positive market outlook highlights the critical role of piston rod seals in various industrial applications and their contribution to the overall efficiency and productivity of operations.

| Report Metric | Details |

| Report Name | Piston Rod Seal Market |

| Accounted market size in 2023 | US$ 545.7 million |

| Forecasted market size in 2030 | US$ 748.8 million |

| CAGR | 4.9% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | SKF, Parker Hannifin, Freudenberg Sealing Technologies, Trelleborg, BORSIG, Gallagher Fluid Seals, Hallite, Sealink Corp, KACO, HUNGER Dichtungen, HAWE Hydraulik, ElringKlinger Kunststofftechnik, AFT Fluorotec, Roger Zatkoff, Pacific Seals, DMR Seals, Voneseals, Burckhardt Compression, Aston Seals |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |