What is Global High Purity Germanium Powder Market?

The Global High Purity Germanium Powder Market is a niche yet significant segment within the broader materials industry, focusing on the production and distribution of germanium powder at high levels of purity. This market caters to a specialized demand for germanium, a metalloid with properties that make it invaluable across various high-tech applications. Germanium's unique characteristics, such as its semiconductor properties, make it a critical material in the manufacture of electronic components, fiber optics, infrared optics, and solar cell applications. The market's emphasis on high purity is crucial because even minor impurities can significantly affect the performance of germanium in these sensitive applications. As industries continue to advance technologically, the demand for high-purity germanium powder grows, driven by its essential role in enhancing the efficiency and performance of electronic devices and renewable energy solutions. The market's dynamics are influenced by technological advancements, global economic conditions, and the development of new applications for germanium. As of 2023, the market is on a path of growth, reflecting the increasing importance of high-purity materials in driving innovation and efficiency in the global technology and energy sectors.

4N, 5N, 6N in the Global High Purity Germanium Powder Market:

Diving into the specifics of the Global High Purity Germanium Powder Market, the distinctions between 4N, 5N, and 6N germanium powders are pivotal. These classifications refer to the purity levels of germanium powder, with "N" denoting "nines" after the decimal in purity percentage. Therefore, 4N purity means the germanium is 99.99% pure, 5N is 99.999% pure, and 6N reaches an even higher purity of 99.9999%. Each step up in purity level represents a significant reduction in impurity content, which is critical for applications where even trace amounts of contaminants can impair performance. The production of such high-purity germanium powder involves sophisticated refining processes, including zone refining and chemical purification, to remove impurities to the parts per billion (ppb) level or lower. The demand for different purity levels varies by application; for instance, semiconductor manufacturing and infrared optics might require 5N purity for its balance of performance and cost, while more demanding applications, such as certain types of high-efficiency solar cells, might necessitate the ultra-high purity of 6N germanium. The market for high purity germanium powder is thus segmented by these purity levels, with each segment catering to specific industrial needs. The development and refinement of purification technologies, along with the expanding range of applications for high-purity germanium, continue to drive the evolution of this market.

Semiconductor Material, Electronic, Solar Cell, Others in the Global High Purity Germanium Powder Market:

The usage of Global High Purity Germanium Powder spans several critical areas, including Semiconductor Material, Electronic, Solar Cell, and Other applications, each benefiting uniquely from the high purity levels of germanium. In the semiconductor industry, germanium powder is used to create germanium wafers, a foundational element for manufacturing semiconductors. The high purity is essential to achieve the desired electrical properties and ensure the reliability of the semiconductors. In electronics, germanium is used in transistors, diodes, and other components where its ability to efficiently conduct electricity at certain temperatures is prized. The solar cell industry benefits from high purity germanium powder in the production of thin-film solar cells, where germanium's excellent photovoltaic properties help convert sunlight into electricity more efficiently. Beyond these applications, high purity germanium powder finds use in fiber optics, infrared optics, and other niche areas where its unique properties can be leveraged for superior performance. The demand in these sectors is driven by the ongoing quest for more efficient, reliable, and high-performance materials that can push the boundaries of current technology and energy solutions. As the global economy continues to emphasize sustainability and technological advancement, the role of high purity germanium powder in these areas is expected to grow, reflecting its critical contribution to innovation and efficiency across a broad spectrum of industries.

Global High Purity Germanium Powder Market Outlook:

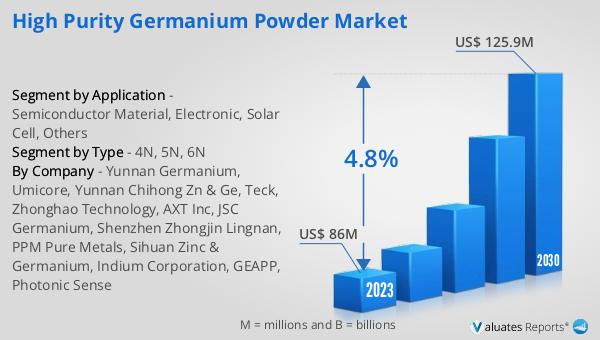

The market outlook for the Global High Purity Germanium Powder Market presents a promising future. As of 2023, the market's valuation stood at US$ 86 million, with projections indicating a climb to US$ 125.9 million by the year 2030. This growth trajectory, expected to unfold at a compound annual growth rate (CAGR) of 4.8% during the forecast period from 2024 to 2030, underscores the increasing demand and expanding applications for high purity germanium powder across various sectors. This optimistic forecast reflects the market's response to the growing need for materials that can meet the stringent requirements of advanced technological applications, from electronics and semiconductors to renewable energy solutions like solar cells. The anticipated growth is a testament to the critical role that high purity germanium powder plays in driving innovation, efficiency, and performance in these key industries. As the market advances, it is poised to benefit from technological improvements, increased investment in research and development, and the expanding scope of applications for germanium, marking a period of significant opportunity and expansion for stakeholders in the Global High Purity Germanium Powder Market.

| Report Metric | Details |

| Report Name | High Purity Germanium Powder Market |

| Accounted market size in 2023 | US$ 86 million |

| Forecasted market size in 2030 | US$ 125.9 million |

| CAGR | 4.8% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Yunnan Germanium, Umicore, Yunnan Chihong Zn & Ge, Teck, Zhonghao Technology, AXT Inc, JSC Germanium, Shenzhen Zhongjin Lingnan, PPM Pure Metals, Sihuan Zinc & Germanium, Indium Corporation, GEAPP, Photonic Sense |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |