What is Global Heat Resisting Alloys Market?

The Global Heat Resisting Alloys Market encompasses a wide range of materials designed to perform exceptionally well in environments of extreme temperature and pressure. These alloys, known for their remarkable strength and resistance to thermal degradation, are pivotal in industries where high performance under stress is a non-negotiable requirement. The market for these alloys is driven by the need for materials that can maintain structural integrity and functionality over prolonged exposure to high temperatures. Heat resisting alloys are crafted from a variety of base metals, each offering unique properties to suit specific applications. The development and innovation in this sector are propelled by the continuous push for efficiency and durability in high-temperature operations, making these alloys indispensable in sectors such as aerospace, power generation, and automotive manufacturing. As industries worldwide strive for advancements in technology and materials science, the demand for heat resisting alloys is expected to surge, reflecting their critical role in modern engineering and manufacturing processes.

Iron Base Superalloy, Nickel Base Superalloy, Cobalt Base Superalloy in the Global Heat Resisting Alloys Market:

Diving into the specifics, the Global Heat Resisting Alloys Market is segmented into three primary categories based on the base metal: Iron Base Superalloy, Nickel Base Superalloy, and Cobalt Base Superalloy. Each category brings its unique set of properties and applications to the table. Iron Base Superalloys are renowned for their exceptional strength and resistance to oxidation and corrosion, making them ideal for high-stress environments at moderate temperatures. They are commonly used in steam turbine power plants and petrochemical installations. Nickel Base Superalloys, on the other hand, are the go-to choice for the highest temperature applications. Their superior thermal stability and resistance to thermal creep deformation make them indispensable in the aerospace industry, particularly in jet engine components where operational conditions are most extreme. Cobalt Base Superalloys, while similar to nickel-based in terms of temperature resistance, offer an added advantage in environments where magnetic properties must be preserved at high temperatures. Their use is prevalent in specialized sectors such as medical implants and certain aerospace applications. The development and utilization of these superalloys are crucial for pushing the boundaries of what's possible in engineering and technology, enabling advancements in efficiency, safety, and performance across a multitude of high-tech industries.

Aerospace, Industrial, Automotive, Mechanical Engineering, Oil & Gas, Power Industry, Others in the Global Heat Resisting Alloys Market:

The usage of the Global Heat Resisting Alloys Market spans across several critical industries, each benefiting from the unique properties these materials offer. In Aerospace, these alloys are fundamental in manufacturing components that can withstand the extreme conditions of flight and space exploration, such as jet engines and spacecraft. The Industrial sector relies on these materials for equipment used in high-temperature processes, including power generation and chemical manufacturing, where durability and resistance to thermal degradation are paramount. In the Automotive industry, heat resisting alloys are used in parts like exhaust systems and turbochargers, enhancing performance and longevity. Mechanical Engineering applications include high-performance gears and bearings that operate under high stress and temperature conditions. The Oil & Gas industry utilizes these alloys in drilling and extraction equipment, where resistance to corrosion and high pressure is critical. In the Power Industry, they are essential for components in nuclear reactors and turbines that require materials capable of withstanding high temperatures and radiation. Other sectors, including electronics and medical devices, also benefit from the specialized properties of heat resisting alloys, underscoring their versatility and importance across a broad spectrum of modern technology and industry.

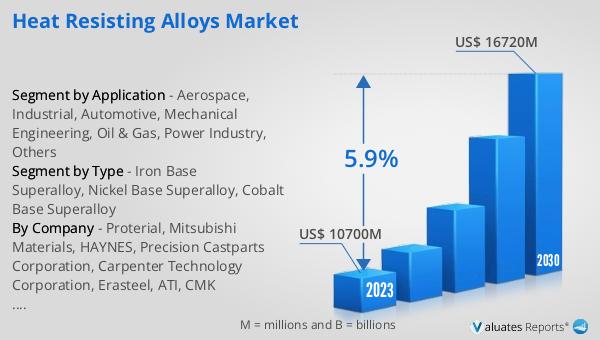

Global Heat Resisting Alloys Market Outlook:

Regarding the market outlook, the Global Heat Resisting Alloys Market is on a trajectory of significant growth. As of 2023, the market's value stood at approximately 10700 million USD. With projections indicating a climb to around 16720 million USD by the year 2030, the market is expected to experience a compound annual growth rate (CAGR) of 5.9% throughout the period spanning from 2024 to 2030. This anticipated growth underscores the increasing demand and expanding applications of heat resisting alloys across various industries. The surge in market value reflects the critical role these materials play in advancing technology and industrial capabilities, catering to the ever-evolving requirements for materials that can perform under extreme conditions. As industries continue to push the boundaries of innovation, the reliance on heat resisting alloys is set to increase, driving the market towards further expansion and development.

| Report Metric | Details |

| Report Name | Heat Resisting Alloys Market |

| Accounted market size in 2023 | US$ 10700 million |

| Forecasted market size in 2030 | US$ 16720 million |

| CAGR | 5.9% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Proterial, Mitsubishi Materials, HAYNES, Precision Castparts Corporation, Carpenter Technology Corporation, Erasteel, ATI, CMK Corporation, Nippon Yakin Kogyo, DONCASTERS GROUP LIMITED, VDM-Metals, Fushun Special Steel, Beijing Cisri-Gaona Materials & Technology, Shenyang Gina, Baowu, Angang Steel Group, Western Superconducting Technologies, Aperam |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |