What is Global Electron Beam System Market?

The Global Electron Beam System Market is a dynamic and rapidly evolving sector that plays a crucial role in various high-tech industries. Electron beam systems are advanced technologies that utilize focused beams of electrons to process materials with high precision and efficiency. These systems are widely used in applications such as welding, surface treatment, and lithography, among others. The market for electron beam systems is driven by the increasing demand for high-quality manufacturing processes that require precision and reliability. Industries such as aerospace, automotive, and electronics are major consumers of these systems due to their need for advanced manufacturing techniques. The market is characterized by continuous technological advancements, with companies investing in research and development to enhance the capabilities and applications of electron beam systems. As industries continue to seek innovative solutions to improve production efficiency and product quality, the demand for electron beam systems is expected to grow. This growth is further supported by the expanding applications of these systems in emerging fields such as nanotechnology and additive manufacturing. Overall, the Global Electron Beam System Market is poised for significant growth, driven by technological advancements and the increasing need for precision manufacturing across various industries.

Experimental type, Production type in the Global Electron Beam System Market:

In the Global Electron Beam System Market, there are two primary types of systems: experimental and production. Experimental electron beam systems are primarily used in research and development settings. These systems are designed to explore new applications and processes, allowing researchers to experiment with different materials and techniques. They are often used in academic institutions, research laboratories, and by companies that are developing new products or processes. Experimental systems are typically more flexible and customizable than production systems, allowing for a wide range of experiments and modifications. They are essential for advancing the understanding of electron beam technology and for developing new applications that can be scaled up for commercial use. On the other hand, production electron beam systems are designed for large-scale manufacturing processes. These systems are used in industries such as automotive, aerospace, and electronics, where high-volume production is required. Production systems are optimized for efficiency, reliability, and repeatability, ensuring that products are manufactured to exact specifications. They are often used for processes such as welding, surface treatment, and additive manufacturing, where precision and consistency are critical. Production systems are typically more robust and automated than experimental systems, allowing for continuous operation and minimal downtime. The choice between experimental and production systems depends on the specific needs of the user. For companies focused on innovation and development, experimental systems provide the flexibility and capability to explore new possibilities. For those focused on manufacturing and production, production systems offer the efficiency and reliability needed to meet high-volume demands. Both types of systems play a crucial role in the Global Electron Beam System Market, supporting a wide range of applications and industries. As technology continues to advance, the capabilities of both experimental and production systems are expected to expand, further driving the growth of the market. The integration of advanced technologies such as artificial intelligence and machine learning is also expected to enhance the performance and capabilities of electron beam systems, opening up new opportunities for innovation and efficiency. Overall, the distinction between experimental and production systems highlights the diverse applications and potential of electron beam technology in the global market.

Semiconductor industry, LED package, Optics, Other in the Global Electron Beam System Market:

The Global Electron Beam System Market finds extensive usage across various industries, including the semiconductor industry, LED packaging, optics, and others. In the semiconductor industry, electron beam systems are crucial for processes such as lithography and inspection. These systems provide the precision and accuracy needed to create the intricate patterns and structures found in semiconductor devices. Electron beam lithography is a key technology used in the fabrication of integrated circuits, enabling the production of smaller and more powerful chips. The demand for electron beam systems in the semiconductor industry is driven by the continuous push for miniaturization and the development of advanced semiconductor technologies. In the LED packaging industry, electron beam systems are used for processes such as surface treatment and bonding. These systems help improve the performance and reliability of LED packages by ensuring strong and durable bonds between components. The use of electron beam systems in LED packaging is driven by the growing demand for energy-efficient lighting solutions and the need for high-quality LED products. In the optics industry, electron beam systems are used for processes such as coating and surface modification. These systems enable the production of high-quality optical components with precise surface properties, essential for applications such as lenses, mirrors, and optical filters. The demand for electron beam systems in the optics industry is driven by the increasing need for advanced optical technologies in fields such as telecommunications, imaging, and laser systems. Beyond these industries, electron beam systems are also used in various other applications, including additive manufacturing, surface engineering, and materials research. The versatility and precision of electron beam systems make them valuable tools for a wide range of processes and industries. As technology continues to advance, the applications of electron beam systems are expected to expand, further driving the growth of the Global Electron Beam System Market. The integration of new technologies and the development of innovative applications will continue to enhance the capabilities and potential of electron beam systems, supporting their use across diverse industries and applications.

Global Electron Beam System Market Outlook:

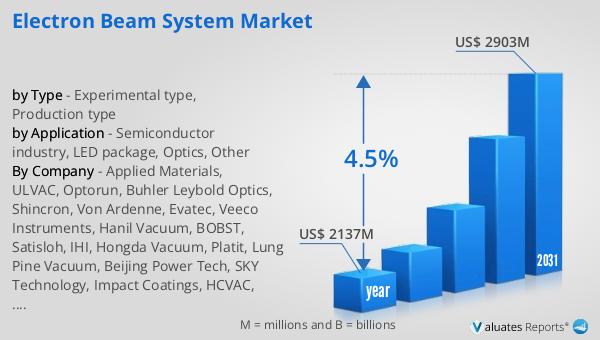

In 2024, the global market for Electron Beam Systems was valued at approximately $2,137 million. This market is anticipated to grow significantly, reaching an estimated value of $2,903 million by the year 2031. This growth represents a compound annual growth rate (CAGR) of 4.5% over the forecast period. The steady increase in market size reflects the rising demand for electron beam systems across various industries, driven by the need for precision manufacturing and advanced processing technologies. As industries continue to evolve and seek innovative solutions to enhance production efficiency and product quality, the demand for electron beam systems is expected to grow. The market's expansion is further supported by the continuous advancements in electron beam technology, which are enhancing the capabilities and applications of these systems. The integration of new technologies and the development of innovative applications are expected to drive the growth of the market, opening up new opportunities for electron beam systems in various industries. Overall, the Global Electron Beam System Market is poised for significant growth, driven by technological advancements and the increasing need for precision manufacturing across various industries.

| Report Metric | Details |

| Report Name | Electron Beam System Market |

| Accounted market size in year | US$ 2137 million |

| Forecasted market size in 2031 | US$ 2903 million |

| CAGR | 4.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Applied Materials, ULVAC, Optorun, Buhler Leybold Optics, Shincron, Von Ardenne, Evatec, Veeco Instruments, Hanil Vacuum, BOBST, Satisloh, IHI, Hongda Vacuum, Platit, Lung Pine Vacuum, Beijing Power Tech, SKY Technology, Impact Coatings, HCVAC, Denton Vacuum, ZHEN HUA, Mustang Vacuum Systems, KYZK |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |