What is Global PCMP Cleaning Chemistry Market?

The Global PCMP Cleaning Chemistry Market is a specialized segment within the broader chemical industry, focusing on the production and application of cleaning agents used in post-chemical mechanical planarization (PCMP) processes. These processes are crucial in the semiconductor manufacturing industry, where they are employed to remove residues and particles from wafer surfaces after planarization. The cleaning chemistry market is driven by the increasing demand for advanced electronic devices, which require highly precise and efficient cleaning solutions to ensure the integrity and performance of semiconductor components. The market encompasses a variety of chemical formulations, each designed to target specific types of contaminants, such as metal impurities, organic residues, and particulate matter. As technology advances, the need for more sophisticated cleaning solutions grows, prompting continuous innovation and development within the market. This market is characterized by its focus on high purity and performance, as even the smallest contamination can significantly impact the functionality of semiconductor devices. The global reach of this market is evident as it serves major semiconductor manufacturing hubs across North America, Asia-Pacific, and Europe, reflecting the interconnected nature of the global electronics supply chain.

Acid Material, Alkaline Material in the Global PCMP Cleaning Chemistry Market:

Acid and alkaline materials play a pivotal role in the Global PCMP Cleaning Chemistry Market, each offering unique properties that cater to different cleaning requirements in semiconductor manufacturing. Acid materials are primarily used to dissolve and remove metal impurities and oxides that may remain on the wafer surface after the planarization process. These materials are formulated to target specific metals, ensuring that they are effectively removed without damaging the underlying substrate. Common acids used in PCMP cleaning include hydrofluoric acid, sulfuric acid, and nitric acid, each selected based on their ability to interact with particular contaminants. The effectiveness of acid-based cleaning solutions is often enhanced by the addition of complexing agents, which help to stabilize the dissolved metals and prevent their redeposition onto the wafer surface. On the other hand, alkaline materials are employed to tackle organic residues and particulate matter. These materials work by breaking down organic compounds into smaller, more manageable molecules that can be easily rinsed away. Alkaline cleaning solutions often contain compounds such as ammonium hydroxide or potassium hydroxide, which provide the necessary pH environment to facilitate the breakdown of organic contaminants. The choice between acid and alkaline materials depends on the specific cleaning requirements and the nature of the contaminants present on the wafer surface. In some cases, a combination of both acid and alkaline cleaning agents may be used to achieve optimal results. The development of these cleaning solutions is guided by the need to balance cleaning efficacy with the preservation of the wafer's structural integrity. As semiconductor devices become more complex, the demand for advanced cleaning chemistries that can address a wider range of contaminants continues to grow. This has led to ongoing research and innovation in the formulation of both acid and alkaline cleaning agents, with a focus on improving their selectivity, efficiency, and environmental impact. The use of acid and alkaline materials in PCMP cleaning is a testament to the intricate balance required in semiconductor manufacturing, where precision and performance are paramount.

Metal Impurities and Particles, Organic Residue in the Global PCMP Cleaning Chemistry Market:

The Global PCMP Cleaning Chemistry Market finds its application in addressing metal impurities and particles, as well as organic residues, which are common contaminants in semiconductor manufacturing. Metal impurities and particles can arise from various sources during the planarization process, including the slurry used in polishing and the equipment itself. These contaminants, if not properly removed, can lead to defects in the semiconductor devices, affecting their performance and reliability. PCMP cleaning chemistries are designed to effectively target and remove these metal impurities and particles, ensuring that the wafer surface is free from any potential sources of contamination. Acid-based cleaning solutions are particularly effective in dissolving metal impurities, while surfactants and dispersants are often added to help suspend and remove particulate matter. Organic residues, on the other hand, are typically the result of the chemical reactions that occur during the planarization process. These residues can form a thin film on the wafer surface, which can interfere with subsequent processing steps if not adequately cleaned. Alkaline cleaning solutions are commonly used to break down and remove these organic residues, ensuring that the wafer surface is clean and ready for further processing. The effectiveness of PCMP cleaning chemistries in removing both metal impurities and organic residues is critical to maintaining the quality and performance of semiconductor devices. As the industry continues to push the boundaries of technology, the need for more advanced cleaning solutions that can address a wider range of contaminants becomes increasingly important. This has led to ongoing research and development in the field of PCMP cleaning chemistry, with a focus on improving the selectivity, efficiency, and environmental impact of these cleaning agents. The ability to effectively remove metal impurities, particles, and organic residues is a key factor in the success of semiconductor manufacturing, and the Global PCMP Cleaning Chemistry Market plays a vital role in supporting this critical industry.

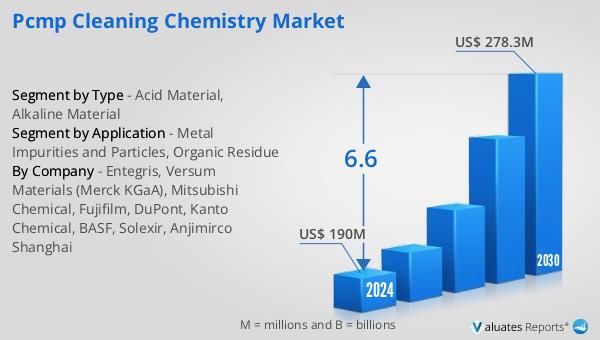

Global PCMP Cleaning Chemistry Market Outlook:

In 2024, the global market for PCMP Cleaning Chemistry was valued at approximately $201 million. This market is anticipated to experience significant growth over the coming years, with projections indicating that it will reach a revised size of around $312 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 6.6% during the forecast period. The expansion of this market can be attributed to several factors, including the increasing demand for advanced electronic devices and the corresponding need for high-precision cleaning solutions in semiconductor manufacturing. As technology continues to evolve, the complexity of semiconductor devices increases, necessitating more sophisticated cleaning chemistries to ensure the integrity and performance of these components. The market's growth is also driven by the ongoing innovation and development of new cleaning formulations that can effectively address a wider range of contaminants, including metal impurities, organic residues, and particulate matter. The global nature of the semiconductor industry further contributes to the market's expansion, as major manufacturing hubs across North America, Asia-Pacific, and Europe require reliable and efficient cleaning solutions to support their production processes. The projected growth of the Global PCMP Cleaning Chemistry Market underscores the critical role that these cleaning agents play in the semiconductor manufacturing industry, highlighting the importance of continued research and development to meet the evolving needs of this dynamic market.

| Report Metric | Details |

| Report Name | PCMP Cleaning Chemistry Market |

| Accounted market size in year | US$ 201 million |

| Forecasted market size in 2031 | US$ 312 million |

| CAGR | 6.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Entegris, Versum Materials (Merck KGaA), Mitsubishi Chemical, Fujifilm, DuPont, Kanto Chemical, BASF, Solexir, Anjimirco Shanghai |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |