What is Global Wire Wound Resistor Market?

The Global Wire Wound Resistor Market is a significant segment within the electronics industry, characterized by its specialized components used to manage electrical current in various applications. Wire wound resistors are precision devices made by winding a metal wire, typically nickel-chromium or similar alloys, around a non-conductive core. This construction allows them to handle high power levels and maintain stability under varying environmental conditions. These resistors are crucial in circuits where precise resistance values are needed, such as in power supplies, amplifiers, and measuring instruments. The market for wire wound resistors is driven by the increasing demand for electronic devices and the need for reliable components that can withstand high temperatures and power surges. As technology advances, the applications for these resistors continue to expand, making them indispensable in both consumer electronics and industrial equipment. The market is also influenced by trends in miniaturization and the development of surface-mount technology, which require resistors that can fit into smaller spaces while maintaining performance. Overall, the Global Wire Wound Resistor Market is poised for growth as industries seek more efficient and durable electronic components.

Axial, Precision, Tubular, Surfacemount, Adjustable in the Global Wire Wound Resistor Market:

Wire wound resistors come in various types, each designed to meet specific needs within the Global Wire Wound Resistor Market. Axial wire wound resistors are among the most common, characterized by their cylindrical shape and leads extending from each end. These resistors are typically used in applications where space is not a major constraint, and they offer excellent stability and precision. Precision wire wound resistors are designed for applications requiring high accuracy and low tolerance levels. They are often used in measuring instruments and calibration devices, where even slight deviations in resistance can lead to significant errors. Tubular wire wound resistors, on the other hand, are designed to handle high power levels and are often used in industrial applications where heat dissipation is a concern. These resistors are typically larger and can be mounted on heat sinks to improve their thermal performance. Surface-mount wire wound resistors are designed for modern electronic devices that require compact components. These resistors are mounted directly onto the surface of a printed circuit board (PCB), allowing for more efficient use of space and improved performance in high-frequency applications. Adjustable wire wound resistors, also known as rheostats, offer the flexibility of changing resistance values as needed. They are commonly used in applications where variable resistance is required, such as in dimmer switches and motor speed controls. Each type of wire wound resistor has its unique advantages and is chosen based on the specific requirements of the application. The diversity in types allows the Global Wire Wound Resistor Market to cater to a wide range of industries, from consumer electronics to heavy machinery, ensuring that there is a suitable resistor for every need. As technology continues to evolve, the demand for these specialized components is expected to grow, driven by the need for more efficient and reliable electronic devices.

Engineering Vehicles, Machine Tools, Welding Equipment, Others in the Global Wire Wound Resistor Market:

The Global Wire Wound Resistor Market finds extensive usage in various sectors, including engineering vehicles, machine tools, welding equipment, and others. In engineering vehicles, wire wound resistors are crucial for managing electrical systems that require precise control of current and voltage. These resistors help in regulating the power supply to different components, ensuring that the vehicle operates efficiently and safely. They are often used in applications such as braking systems, where they help dissipate excess energy and prevent overheating. In machine tools, wire wound resistors play a vital role in controlling the speed and torque of motors. These resistors are used in variable frequency drives (VFDs) and other motor control systems to ensure smooth operation and precise control of machining processes. The ability to handle high power levels and maintain stability under varying conditions makes wire wound resistors ideal for use in demanding industrial environments. In welding equipment, wire wound resistors are used to control the current flow and ensure consistent welding performance. They help in maintaining the desired temperature and preventing fluctuations that could affect the quality of the weld. The durability and reliability of wire wound resistors make them suitable for use in harsh welding environments where they are exposed to high temperatures and mechanical stress. Beyond these specific applications, wire wound resistors are also used in a variety of other industries, including telecommunications, aerospace, and consumer electronics. Their ability to provide precise resistance values and handle high power levels makes them indispensable in circuits where accuracy and reliability are paramount. As industries continue to advance and the demand for more efficient and reliable electronic components grows, the Global Wire Wound Resistor Market is expected to expand, offering new opportunities for innovation and development.

Global Wire Wound Resistor Market Outlook:

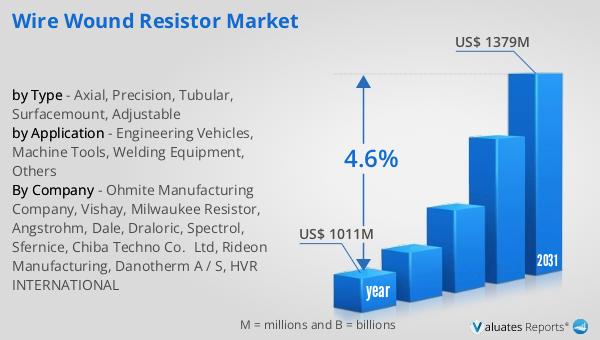

The global market for wire wound resistors was valued at approximately $1,011 million in 2024, and it is anticipated to grow to a revised size of around $1,379 million by 2031. This growth represents a compound annual growth rate (CAGR) of 4.6% over the forecast period. This steady growth can be attributed to the increasing demand for electronic devices and the need for reliable components that can withstand high temperatures and power surges. As industries continue to advance and the demand for more efficient and reliable electronic components grows, the Global Wire Wound Resistor Market is expected to expand, offering new opportunities for innovation and development. The market's growth is also driven by trends in miniaturization and the development of surface-mount technology, which require resistors that can fit into smaller spaces while maintaining performance. The diversity in types allows the Global Wire Wound Resistor Market to cater to a wide range of industries, from consumer electronics to heavy machinery, ensuring that there is a suitable resistor for every need. As technology continues to evolve, the demand for these specialized components is expected to grow, driven by the need for more efficient and reliable electronic devices.

| Report Metric | Details |

| Report Name | Wire Wound Resistor Market |

| Accounted market size in year | US$ 1011 million |

| Forecasted market size in 2031 | US$ 1379 million |

| CAGR | 4.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Ohmite Manufacturing Company, Vishay, Milwaukee Resistor, Angstrohm, Dale, Draloric, Spectrol, Sfernice, Chiba Techno Co.,Ltd, Rideon Manufacturing, Danotherm A / S, HVR INTERNATIONAL |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |