What is Global Automatic Capsule Filling Machines Market?

The Global Automatic Capsule Filling Machines Market refers to the industry focused on the production and distribution of machines designed to fill capsules with various substances, such as powders, granules, or liquids. These machines are essential in the pharmaceutical, nutraceutical, and food industries, where precise and efficient capsule filling is crucial. Automatic capsule filling machines streamline the production process by automating the filling, sealing, and packaging of capsules, thereby reducing labor costs and increasing production efficiency. The market for these machines is driven by the growing demand for pharmaceuticals and dietary supplements, as well as advancements in technology that enhance the accuracy and speed of capsule filling. Additionally, the increasing focus on health and wellness has led to a rise in the consumption of dietary supplements, further boosting the demand for capsule filling machines. As a result, manufacturers are continuously innovating to develop machines that offer higher output rates, improved accuracy, and greater flexibility in handling different capsule sizes and fill materials. The market is characterized by a mix of established players and new entrants, all striving to capture a share of this growing industry by offering advanced and cost-effective solutions.

Semi-Automatic Capsule Filling Machines, Fully Automatic Capsule Filling Machines, Manual Capsule Filling Machines in the Global Automatic Capsule Filling Machines Market:

In the realm of capsule filling machines, there are three primary types: semi-automatic, fully automatic, and manual. Semi-automatic capsule filling machines are designed to offer a balance between manual labor and automation. These machines require human intervention for certain tasks, such as loading empty capsules and removing filled ones, but automate the actual filling process. This type of machine is ideal for small to medium-sized production runs, where flexibility and cost-effectiveness are important. They are often used by small pharmaceutical companies or research laboratories that need to produce a variety of capsule types without investing in fully automated systems. On the other hand, fully automatic capsule filling machines represent the pinnacle of efficiency and productivity in the capsule filling industry. These machines are capable of handling large-scale production with minimal human intervention. They automate the entire process, from capsule loading to filling, sealing, and ejection, ensuring high-speed production and consistent quality. Fully automatic machines are typically used by large pharmaceutical manufacturers that require high output and precision. They are equipped with advanced features such as touch-screen interfaces, real-time monitoring, and the ability to handle different capsule sizes and fill materials. Lastly, manual capsule filling machines are the most basic type, relying entirely on human labor for the filling process. These machines are typically used for very small production runs or in situations where automation is not feasible. They are cost-effective and easy to operate, making them suitable for small businesses or startups that are just entering the market. Despite their simplicity, manual machines require skilled operators to ensure accuracy and consistency in the filling process. Each type of capsule filling machine has its own advantages and limitations, and the choice of machine depends on factors such as production volume, budget, and specific industry requirements. As the demand for capsules continues to grow, manufacturers are constantly innovating to improve the efficiency, accuracy, and versatility of these machines, ensuring they meet the evolving needs of the market.

Pharmaceutical, Cosmetics, Others in the Global Automatic Capsule Filling Machines Market:

The Global Automatic Capsule Filling Machines Market finds extensive usage across various sectors, with the pharmaceutical industry being the most prominent. In pharmaceuticals, these machines are indispensable for the mass production of medications in capsule form. They ensure precise dosage and uniformity, which are critical for patient safety and efficacy of the drugs. The automation of the capsule filling process reduces the risk of contamination and human error, thereby enhancing the overall quality of the pharmaceutical products. Moreover, the ability to handle different capsule sizes and fill materials allows pharmaceutical companies to produce a wide range of products, from prescription medications to over-the-counter supplements. In the cosmetics industry, automatic capsule filling machines are used to encapsulate beauty and skincare products. These capsules often contain active ingredients that are sensitive to environmental factors, and encapsulation helps protect them from degradation. The use of capsules in cosmetics also offers convenience and precise dosing for consumers, enhancing the appeal of the products. Additionally, the trend towards personalized skincare solutions has led to an increase in demand for capsule-based products, further driving the need for efficient filling machines. Beyond pharmaceuticals and cosmetics, automatic capsule filling machines are also utilized in other industries, such as food and nutraceuticals. In the food industry, these machines are used to encapsulate flavors, vitamins, and other additives, ensuring consistent quality and taste. The nutraceutical industry, which focuses on products that provide health benefits beyond basic nutrition, relies heavily on capsule filling machines to produce dietary supplements. The growing consumer awareness of health and wellness has led to an increase in the consumption of nutraceuticals, thereby boosting the demand for capsule filling machines. Overall, the versatility and efficiency of automatic capsule filling machines make them an essential tool across various industries, enabling manufacturers to meet the growing demand for high-quality, safe, and effective products.

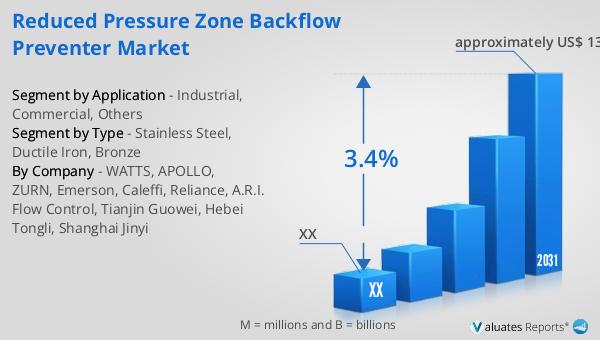

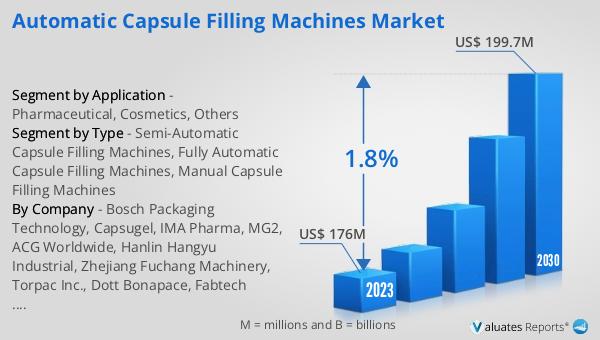

Global Automatic Capsule Filling Machines Market Outlook:

The global market for automatic capsule filling machines was valued at $182 million in 2024 and is anticipated to expand to a revised size of $206 million by 2031, reflecting a compound annual growth rate (CAGR) of 1.8% over the forecast period. This market is characterized by a few key players, including IMA Pharma, Torpac, Harro Höfliger, Fabtech Technologies, and Zhejiang Fuchang Machinery, which collectively account for approximately 30% of the market share. The Asia-Pacific region emerges as the largest market, holding a share exceeding 35%, indicating a significant demand for these machines in the region. Among the various types of capsule filling machines, fully automatic machines are the most prevalent, capturing over 63% of the market share. This preference is largely due to their efficiency and ability to handle large-scale production with minimal human intervention. In terms of application, the pharmaceutical industry dominates the market, with a share of about 95%. This overwhelming majority underscores the critical role that automatic capsule filling machines play in the production of pharmaceuticals, where precision, speed, and hygiene are paramount. As the market continues to evolve, manufacturers are focusing on innovation and technological advancements to meet the diverse needs of their customers and maintain a competitive edge.

| Report Metric | Details |

| Report Name | Automatic Capsule Filling Machines Market |

| Accounted market size in year | US$ 182 million |

| Forecasted market size in 2031 | US$ 206 million |

| CAGR | 1.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Bosch Packaging Technology, Capsugel, IMA Pharma, MG2, ACG Worldwide, Hanlin Hangyu Industrial, Zhejiang Fuchang Machinery, Torpac Inc., Dott Bonapace, Fabtech Technologies, Harro Hfliger, Karnavati, Sejong, Qualicaps |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |