What is Global Torque Wrench Drive Insert Market?

The Global Torque Wrench Drive Insert Market is a specialized segment within the broader tool and equipment industry, focusing on the production and distribution of torque wrench drive inserts. These inserts are crucial components used in torque wrenches, which are tools designed to apply a specific torque to a fastener such as a nut or bolt. The market encompasses a variety of drive inserts that cater to different types of torque wrenches, including manual, electronic, and hydraulic models. The demand for these inserts is driven by their essential role in ensuring precision and accuracy in fastening applications across various industries. As industries continue to prioritize efficiency and safety, the need for reliable torque wrench drive inserts has become increasingly significant. The market is characterized by a diverse range of products, each designed to meet specific requirements and standards, thereby catering to a wide array of applications. This market is also influenced by technological advancements, which have led to the development of more sophisticated and durable inserts, enhancing their performance and lifespan. As a result, the Global Torque Wrench Drive Insert Market is poised for steady growth, driven by ongoing industrialization and the increasing complexity of machinery and equipment.

Square Type, Ratchet Type, Others in the Global Torque Wrench Drive Insert Market:

In the Global Torque Wrench Drive Insert Market, there are several types of inserts, each serving distinct purposes and applications. The Square Type insert is one of the most common and widely used. It is characterized by its square-shaped drive, which fits into the corresponding square socket of a torque wrench. This type is favored for its simplicity and versatility, making it suitable for a wide range of applications. Square Type inserts are typically used in situations where a straightforward, reliable connection is needed, and they are available in various sizes to accommodate different torque requirements. Their robust design ensures durability and long-term performance, making them a staple in many toolkits. The Ratchet Type insert, on the other hand, is designed to provide more flexibility and ease of use. It incorporates a ratcheting mechanism that allows for continuous rotation in one direction while preventing movement in the opposite direction. This feature is particularly useful in tight or confined spaces where a full rotation of the wrench is not possible. Ratchet Type inserts are highly valued in applications that require frequent adjustments or where speed is a priority. They are often used in automotive and mechanical industries, where precision and efficiency are crucial. The ratcheting action not only saves time but also reduces the physical effort required, making it a popular choice among professionals. Apart from the Square and Ratchet Types, there are other specialized inserts designed for specific applications. These include hex, spline, and star-shaped inserts, each offering unique advantages. Hex inserts, for example, are commonly used in applications involving hexagonal fasteners, providing a secure grip and minimizing the risk of slippage. Spline inserts are designed for high-torque applications, offering superior strength and durability. They are often used in heavy machinery and industrial equipment, where maximum torque is required. Star-shaped inserts, also known as Torx inserts, are used in applications where tamper resistance is important, as their unique design makes them difficult to remove without the proper tool. The diversity of inserts in the Global Torque Wrench Drive Insert Market reflects the wide range of applications and industries they serve. Each type of insert is engineered to meet specific needs, ensuring that users can achieve the desired level of precision and performance. As industries continue to evolve and demand more specialized tools, the market for torque wrench drive inserts is expected to expand, offering new opportunities for innovation and growth. Manufacturers are continually exploring new materials and designs to enhance the functionality and durability of these inserts, ensuring they remain an essential component in the toolkit of professionals across various sectors.

Construction Industry, Manufacturing, Others in the Global Torque Wrench Drive Insert Market:

The Global Torque Wrench Drive Insert Market finds extensive usage across several key industries, with the construction industry being one of the primary sectors. In construction, torque wrench drive inserts are essential for assembling and securing structural components. They ensure that bolts and fasteners are tightened to the precise specifications required for safety and stability. This precision is crucial in construction projects, where even minor deviations can lead to significant structural issues. Torque wrench drive inserts are used in various construction applications, from erecting steel frameworks to installing heavy machinery. Their ability to deliver consistent and accurate torque makes them indispensable tools for construction professionals. In the manufacturing sector, torque wrench drive inserts play a vital role in assembly lines and production processes. They are used to ensure that components are fastened correctly, preventing defects and ensuring product quality. In industries such as automotive and aerospace, where precision is paramount, torque wrench drive inserts are used to assemble engines, chassis, and other critical components. The use of these inserts helps maintain consistency and reliability in manufacturing processes, reducing the risk of product failures and recalls. As manufacturing processes become more automated and sophisticated, the demand for high-quality torque wrench drive inserts is expected to increase. Beyond construction and manufacturing, torque wrench drive inserts are used in a variety of other industries, including energy, transportation, and maintenance. In the energy sector, they are used in the assembly and maintenance of equipment such as wind turbines and pipelines, where precise torque application is essential for safety and efficiency. In transportation, torque wrench drive inserts are used in the maintenance and repair of vehicles, ensuring that components are securely fastened and operating correctly. In maintenance and repair operations, these inserts are used to service a wide range of equipment, from industrial machinery to household appliances. The versatility and reliability of torque wrench drive inserts make them valuable tools across these diverse applications. Their ability to deliver precise torque ensures that fasteners are tightened to the correct specifications, reducing the risk of equipment failure and enhancing safety. As industries continue to prioritize efficiency and quality, the demand for torque wrench drive inserts is expected to grow, driving innovation and development in this market. Manufacturers are continually seeking to improve the performance and durability of these inserts, ensuring they meet the evolving needs of their customers.

Global Torque Wrench Drive Insert Market Outlook:

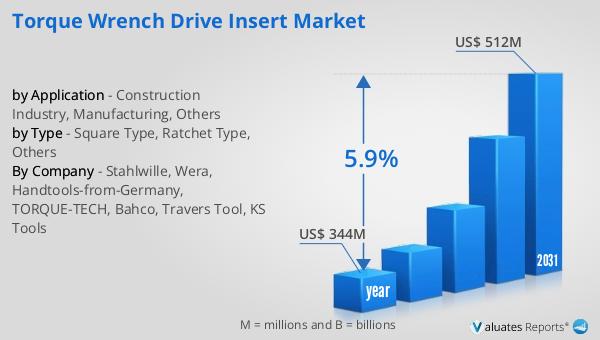

The global market for Torque Wrench Drive Insert was valued at $344 million in 2024, with projections indicating a growth to $512 million by 2031. This growth represents a compound annual growth rate (CAGR) of 5.9% over the forecast period. This upward trend reflects the increasing demand for precision tools across various industries, driven by the need for accuracy and efficiency in fastening applications. The market's expansion is supported by technological advancements that have led to the development of more sophisticated and durable torque wrench drive inserts. These innovations have enhanced the performance and lifespan of the inserts, making them more appealing to a broad range of industries. As industries continue to evolve and prioritize safety and efficiency, the demand for high-quality torque wrench drive inserts is expected to rise. This growth trajectory underscores the importance of these tools in modern industrial applications, highlighting their role in ensuring the reliability and safety of machinery and equipment. The market's positive outlook is a testament to the ongoing industrialization and the increasing complexity of machinery, which necessitates the use of precise and reliable tools.

| Report Metric | Details |

| Report Name | Torque Wrench Drive Insert Market |

| Accounted market size in year | US$ 344 million |

| Forecasted market size in 2031 | US$ 512 million |

| CAGR | 5.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Stahlwille, Wera, Handtools-from-Germany, TORQUE-TECH, Bahco, Travers Tool, KS Tools |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |