What is Global High-Performance NdFeB Permanent Magnet Materials Market?

The Global High-Performance NdFeB Permanent Magnet Materials Market is a dynamic and rapidly evolving sector that plays a crucial role in various industries worldwide. NdFeB, or Neodymium-Iron-Boron, magnets are known for their exceptional magnetic strength and are considered the strongest type of permanent magnets available today. These magnets are composed of an alloy of neodymium, iron, and boron, which gives them their high-performance characteristics. The market for these materials is driven by their widespread application in numerous fields, including electronics, automotive, energy, and healthcare. As industries continue to innovate and demand more efficient and compact solutions, the need for high-performance NdFeB magnets has surged. These magnets are integral in the production of electric vehicles, wind turbines, and various electronic devices, contributing to energy efficiency and technological advancement. The market's growth is also fueled by the increasing emphasis on renewable energy sources and the need for sustainable solutions. As a result, the Global High-Performance NdFeB Permanent Magnet Materials Market is poised for significant expansion, reflecting the broader trends of technological progress and environmental consciousness.

Sintered NdFeB Magnets, Bonded NdFeB Magnets, Others in the Global High-Performance NdFeB Permanent Magnet Materials Market:

Sintered NdFeB Magnets, Bonded NdFeB Magnets, and other types of NdFeB magnets each have unique characteristics and applications within the Global High-Performance NdFeB Permanent Magnet Materials Market. Sintered NdFeB magnets are created through a process of powder metallurgy, where the powdered form of the alloy is pressed into a mold and then heated to form a solid piece. This method results in magnets with high magnetic strength and excellent resistance to demagnetization. Sintered NdFeB magnets are widely used in applications that require strong magnetic fields, such as electric motors, generators, and magnetic resonance imaging (MRI) machines. Their ability to maintain performance under high temperatures makes them ideal for demanding environments. On the other hand, Bonded NdFeB magnets are produced by combining NdFeB powder with a binding agent, typically a type of plastic or resin, and then compressing the mixture into the desired shape. This process allows for more complex shapes and sizes, offering greater flexibility in design. Although bonded magnets generally have lower magnetic strength compared to sintered magnets, they are valued for their versatility and cost-effectiveness. They are commonly used in applications like sensors, small motors, and consumer electronics where space and weight are critical considerations. Additionally, bonded magnets exhibit excellent corrosion resistance, making them suitable for use in environments where moisture or chemicals are present. Beyond these two primary types, the market also includes other variations of NdFeB magnets, each tailored for specific applications. These may include isotropic and anisotropic magnets, which differ in their magnetic orientation and performance characteristics. Isotropic magnets can be magnetized in any direction, offering flexibility in their use, while anisotropic magnets are magnetized in a specific direction, providing higher magnetic performance. The choice between these types depends on the specific requirements of the application, such as the need for high precision, strength, or resistance to environmental factors. Overall, the diversity of NdFeB magnet types within the market allows for a wide range of applications, catering to the needs of various industries and driving the continued growth and innovation in the field of high-performance magnet materials.

Energy Saving and Environmental Protection, Medicine, Automobile, Consumer Electronics, Others in the Global High-Performance NdFeB Permanent Magnet Materials Market:

The Global High-Performance NdFeB Permanent Magnet Materials Market finds extensive usage across several key areas, including energy saving and environmental protection, medicine, automobile, consumer electronics, and others. In the realm of energy saving and environmental protection, NdFeB magnets are pivotal in the development of renewable energy technologies. They are essential components in wind turbines, where their strong magnetic fields help convert wind energy into electricity efficiently. This contributes to the reduction of carbon emissions and supports the global shift towards sustainable energy sources. Additionally, these magnets are used in energy-efficient appliances and systems, such as HVAC units and smart meters, which help reduce energy consumption and promote environmental conservation. In the medical field, NdFeB magnets are integral to the functioning of MRI machines, which rely on strong magnetic fields to produce detailed images of the human body. These magnets enable non-invasive diagnostic procedures, improving patient care and outcomes. Furthermore, they are used in medical devices like hearing aids and pacemakers, where their compact size and high performance are crucial. The automobile industry also benefits significantly from NdFeB magnets, particularly in the production of electric and hybrid vehicles. These magnets are used in electric motors and generators, enhancing the efficiency and performance of vehicles while reducing reliance on fossil fuels. As the demand for eco-friendly transportation solutions grows, the role of NdFeB magnets in the automotive sector is expected to expand further. In consumer electronics, NdFeB magnets are found in a wide range of devices, from smartphones and laptops to headphones and speakers. Their ability to provide strong magnetic fields in compact sizes makes them ideal for modern electronic gadgets, which require high performance in small form factors. This has led to their widespread adoption in the electronics industry, driving innovation and enhancing user experiences. Beyond these areas, NdFeB magnets are also used in various other applications, such as robotics, aerospace, and industrial machinery, where their unique properties contribute to improved performance and efficiency. The versatility and effectiveness of NdFeB magnets across these diverse sectors underscore their importance in the global market and highlight their role in advancing technology and sustainability.

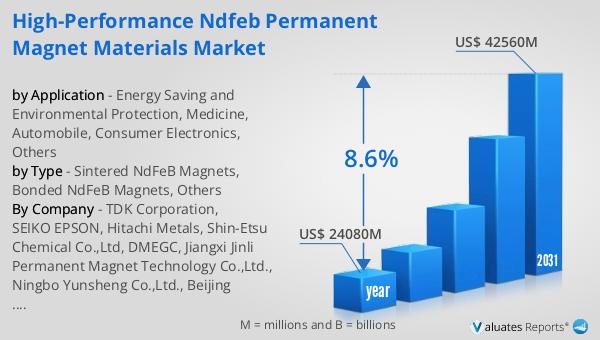

Global High-Performance NdFeB Permanent Magnet Materials Market Outlook:

The global market for High-Performance NdFeB Permanent Magnet Materials was valued at $24,080 million in 2024, and it is anticipated to grow significantly, reaching an estimated value of $42,560 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 8.6% over the forecast period. This impressive expansion is driven by the increasing demand for high-performance magnets across various industries, including automotive, electronics, and renewable energy. As industries continue to innovate and seek more efficient solutions, the need for NdFeB magnets, known for their exceptional magnetic strength and versatility, is expected to rise. The automotive sector, in particular, is a major contributor to this growth, with the rising production of electric and hybrid vehicles that rely heavily on these magnets for their motors and generators. Similarly, the electronics industry benefits from the compact size and high performance of NdFeB magnets, which are essential in the development of modern gadgets and devices. Additionally, the push towards renewable energy sources, such as wind and solar power, further fuels the demand for these magnets, as they play a critical role in the efficiency and effectiveness of energy conversion systems. Overall, the market outlook for High-Performance NdFeB Permanent Magnet Materials is promising, reflecting the broader trends of technological advancement and environmental sustainability.

| Report Metric | Details |

| Report Name | High-Performance NdFeB Permanent Magnet Materials Market |

| Accounted market size in year | US$ 24080 million |

| Forecasted market size in 2031 | US$ 42560 million |

| CAGR | 8.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | TDK Corporation, SEIKO EPSON, Hitachi Metals, Shin-Etsu Chemical Co.,Ltd, DMEGC, Jiangxi Jinli Permanent Magnet Technology Co.,Ltd., Ningbo Yunsheng Co.,Ltd., Beijing Zhongke Sanhuan Hi-Tech Co.,Ltd., Beikuang Magnetic Materials Technology Co.,Ltd., Yantai Zhenghai Magnetic, Anhui Earth Bear New Material Co.,Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |