What is Global Resistance Furnace Smelting Transformers Market?

The Global Resistance Furnace Smelting Transformers Market is a specialized segment within the broader transformer industry, focusing on transformers used in resistance furnace applications. These transformers are crucial in processes that require precise temperature control and energy efficiency, such as smelting and heat treatment. Resistance furnace smelting transformers are designed to handle high currents and low voltages, making them ideal for industrial applications where metals and other materials are melted or treated at high temperatures. The market for these transformers is driven by the growing demand for efficient and reliable power solutions in industries like metallurgy, manufacturing, and energy. As industries continue to expand and modernize, the need for advanced smelting transformers that can support high-performance operations becomes increasingly important. This market is characterized by technological advancements, with manufacturers focusing on developing transformers that offer improved efficiency, durability, and environmental sustainability. The global reach of this market is evident as it caters to diverse industrial needs across different regions, adapting to varying regulatory standards and energy requirements. The continuous evolution of industrial processes and the emphasis on energy conservation further propel the demand for innovative solutions in the Global Resistance Furnace Smelting Transformers Market.

Oil Filled Transformers, Dry Type Transformers in the Global Resistance Furnace Smelting Transformers Market:

Oil-filled transformers and dry-type transformers are two primary categories within the Global Resistance Furnace Smelting Transformers Market, each offering distinct advantages and applications. Oil-filled transformers are widely used due to their excellent cooling and insulation properties. They are filled with a special insulating oil that helps dissipate heat generated during operation, ensuring the transformer remains cool and operates efficiently. This type of transformer is particularly suitable for high-capacity applications where heat management is crucial. The oil not only acts as a coolant but also provides insulation, protecting the transformer from electrical faults and enhancing its longevity. Oil-filled transformers are often preferred in outdoor installations or environments where space is not a constraint, as they require additional safety measures to prevent oil leaks and potential fire hazards. On the other hand, dry-type transformers are gaining popularity due to their safety and environmental benefits. Unlike oil-filled transformers, dry-type transformers use air or other non-flammable materials for cooling and insulation. This makes them ideal for indoor applications or areas where fire safety is a significant concern. Dry-type transformers are known for their robustness and low maintenance requirements, as they do not involve any liquid that could leak or require regular replacement. They are also more environmentally friendly, as they eliminate the risk of oil spills and reduce the need for oil disposal. In the context of resistance furnace smelting, both oil-filled and dry-type transformers play crucial roles. Oil-filled transformers are often used in large-scale industrial operations where high power capacity and efficient heat management are essential. Their ability to handle high loads and provide stable performance makes them suitable for demanding smelting processes. Meanwhile, dry-type transformers are preferred in settings where safety and environmental considerations are paramount. They are commonly used in facilities with stringent safety regulations or in urban areas where minimizing environmental impact is a priority. The choice between oil-filled and dry-type transformers in the Global Resistance Furnace Smelting Transformers Market depends on various factors, including the specific requirements of the application, the operating environment, and regulatory considerations. As industries continue to evolve and prioritize sustainability, the demand for both types of transformers is expected to grow, with manufacturers focusing on enhancing their efficiency, reliability, and environmental performance. The ongoing advancements in transformer technology, such as the development of eco-friendly insulating materials and improved cooling systems, further contribute to the dynamic nature of this market.

Smelt, Heat Treatment, Others in the Global Resistance Furnace Smelting Transformers Market:

The Global Resistance Furnace Smelting Transformers Market finds its applications in various areas, including smelting, heat treatment, and other industrial processes. In smelting, these transformers are essential for converting raw materials into refined metals. The process involves heating ores to high temperatures to extract metals like iron, copper, and aluminum. Resistance furnace smelting transformers provide the necessary power to achieve and maintain these high temperatures, ensuring efficient and consistent smelting operations. Their ability to handle high currents and low voltages makes them ideal for smelting applications, where precise temperature control is crucial for producing high-quality metals. In heat treatment, resistance furnace smelting transformers play a vital role in processes that alter the physical and chemical properties of materials. Heat treatment involves heating and cooling materials, such as metals and alloys, to achieve desired characteristics like increased strength, hardness, or ductility. Transformers used in these applications must provide stable and reliable power to ensure uniform heating and cooling cycles. The precision and efficiency of resistance furnace smelting transformers make them indispensable in heat treatment processes, where even minor variations in temperature can significantly impact the final product's quality. Beyond smelting and heat treatment, resistance furnace smelting transformers are used in various other industrial applications that require controlled heating. These include processes like annealing, tempering, and sintering, where materials are subjected to specific temperature profiles to achieve desired properties. The versatility of these transformers allows them to be adapted for different industrial needs, providing reliable power solutions across a wide range of applications. As industries continue to innovate and develop new materials and processes, the demand for advanced resistance furnace smelting transformers is expected to grow. Manufacturers are focusing on enhancing the performance and efficiency of these transformers to meet the evolving needs of industrial applications. This includes developing transformers with improved energy efficiency, reduced environmental impact, and enhanced durability to withstand the demanding conditions of industrial operations. The Global Resistance Furnace Smelting Transformers Market is poised for growth as industries seek reliable and efficient power solutions to support their operations.

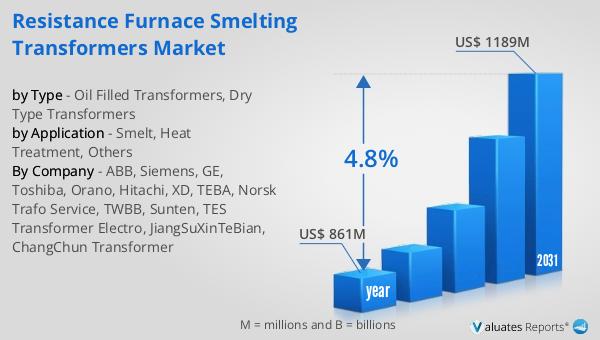

Global Resistance Furnace Smelting Transformers Market Outlook:

The global market for Resistance Furnace Smelting Transformers was valued at $861 million in 2024 and is anticipated to expand to a revised size of $1,189 million by 2031, reflecting a compound annual growth rate (CAGR) of 4.8% during the forecast period. This growth trajectory highlights the increasing demand for these specialized transformers across various industrial sectors. The market's expansion is driven by the need for efficient and reliable power solutions in industries such as metallurgy, manufacturing, and energy. As these industries continue to evolve and modernize, the demand for advanced smelting transformers that can support high-performance operations becomes increasingly important. The market's growth is also supported by technological advancements, with manufacturers focusing on developing transformers that offer improved efficiency, durability, and environmental sustainability. The global reach of this market is evident as it caters to diverse industrial needs across different regions, adapting to varying regulatory standards and energy requirements. The continuous evolution of industrial processes and the emphasis on energy conservation further propel the demand for innovative solutions in the Global Resistance Furnace Smelting Transformers Market. As industries prioritize sustainability and efficiency, the market for these transformers is expected to continue its upward trajectory, offering significant opportunities for growth and innovation.

| Report Metric | Details |

| Report Name | Resistance Furnace Smelting Transformers Market |

| Accounted market size in year | US$ 861 million |

| Forecasted market size in 2031 | US$ 1189 million |

| CAGR | 4.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | ABB, Siemens, GE, Toshiba, Orano, Hitachi, XD, TEBA, Norsk Trafo Service, TWBB, Sunten, TES Transformer Electro, JiangSuXinTeBian, ChangChun Transformer |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |