What is Global Electrical Busbar Tray Market?

The Global Electrical Busbar Tray Market is a significant segment within the electrical infrastructure industry, focusing on the distribution of electrical power through busbar systems. These systems are essential for efficiently conducting electricity in various settings, including commercial, industrial, and residential buildings. Busbar trays are designed to support and protect busbars, which are metallic strips or bars used for local high current power distribution. The market for these trays is driven by the increasing demand for reliable and efficient power distribution solutions, especially in regions experiencing rapid urbanization and industrialization. As the world moves towards more sustainable energy solutions, the need for efficient electrical distribution systems like busbar trays becomes even more critical. These trays not only ensure the safe and efficient distribution of electricity but also help in reducing energy losses, making them an integral part of modern electrical infrastructure. The market is characterized by a variety of materials used in the manufacturing of busbar trays, including aluminum and copper, each offering distinct advantages in terms of conductivity, durability, and cost-effectiveness. As the demand for electricity continues to grow globally, the Global Electrical Busbar Tray Market is poised for significant growth, driven by technological advancements and the increasing need for efficient power distribution systems.

Aluminium Tray, Copper Tray in the Global Electrical Busbar Tray Market:

Aluminum and copper trays are pivotal components in the Global Electrical Busbar Tray Market, each offering unique benefits that cater to different needs within the electrical distribution landscape. Aluminum trays are favored for their lightweight nature and cost-effectiveness, making them an attractive option for large-scale installations where weight and budget are critical considerations. Aluminum's excellent conductivity and resistance to corrosion further enhance its appeal, ensuring long-term reliability and performance in various environmental conditions. These trays are particularly suitable for applications where weight savings can lead to reduced structural support requirements, thereby lowering overall installation costs. On the other hand, copper trays are renowned for their superior electrical conductivity, which is crucial for applications requiring high current carrying capacity. Copper's inherent strength and durability make it an ideal choice for environments where mechanical robustness is essential. Despite being more expensive than aluminum, copper trays offer long-term value through their exceptional performance and longevity. The choice between aluminum and copper trays often depends on specific project requirements, including budget constraints, environmental conditions, and electrical load demands. In some cases, a combination of both materials may be employed to optimize performance and cost-efficiency. The versatility of aluminum and copper trays allows them to be used in a wide range of applications, from commercial buildings to industrial facilities, each benefiting from the unique properties of these materials. As the Global Electrical Busbar Tray Market continues to evolve, advancements in material technology and manufacturing processes are expected to further enhance the performance and cost-effectiveness of both aluminum and copper trays, ensuring their continued relevance in the ever-changing landscape of electrical power distribution.

Commercial Building, Industrial Building, Others in the Global Electrical Busbar Tray Market:

The Global Electrical Busbar Tray Market finds extensive usage across various sectors, including commercial buildings, industrial buildings, and other applications, each benefiting from the unique advantages offered by busbar systems. In commercial buildings, busbar trays are integral to the efficient distribution of electricity, supporting the complex electrical infrastructure required to power offices, retail spaces, and other commercial establishments. The flexibility and scalability of busbar systems make them ideal for accommodating the dynamic electrical needs of commercial buildings, where changes in layout and usage patterns are common. By providing a reliable and efficient means of power distribution, busbar trays help reduce energy losses and enhance the overall energy efficiency of commercial buildings. In industrial buildings, the demand for robust and high-capacity electrical distribution systems is paramount, given the heavy machinery and equipment typically used in such environments. Busbar trays offer the necessary durability and performance to meet these demands, ensuring the safe and efficient distribution of electricity across large industrial facilities. The ability to handle high current loads and withstand harsh environmental conditions makes busbar trays an indispensable component of industrial electrical infrastructure. Beyond commercial and industrial buildings, busbar trays are also used in a variety of other applications, including residential complexes, data centers, and renewable energy installations. In residential settings, busbar systems provide a safe and efficient means of distributing electricity throughout multi-unit dwellings, while in data centers, they support the high-density power requirements of modern computing infrastructure. In renewable energy installations, busbar trays facilitate the integration of solar and wind power systems into the electrical grid, supporting the transition to more sustainable energy sources. The versatility and adaptability of busbar trays make them a critical component of modern electrical infrastructure, capable of meeting the diverse needs of various sectors and applications. As the demand for efficient and reliable power distribution solutions continues to grow, the Global Electrical Busbar Tray Market is well-positioned to play a key role in shaping the future of electrical infrastructure.

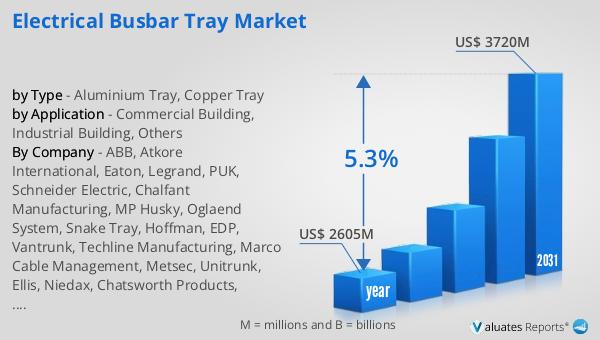

Global Electrical Busbar Tray Market Outlook:

The global market for Electrical Busbar Tray was valued at approximately $2,605 million in 2024, and it is anticipated to expand to a revised size of around $3,720 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 5.3% over the forecast period. This upward trend in the market is indicative of the increasing demand for efficient and reliable power distribution solutions across various sectors. The growth is driven by several factors, including the rapid pace of urbanization and industrialization, which necessitates the development of robust electrical infrastructure to support expanding cities and industries. Additionally, the shift towards more sustainable energy solutions is fueling the demand for advanced electrical distribution systems like busbar trays, which offer enhanced efficiency and reduced energy losses. As technological advancements continue to improve the performance and cost-effectiveness of busbar trays, the market is expected to witness sustained growth, catering to the evolving needs of commercial, industrial, and residential sectors. The projected growth of the Global Electrical Busbar Tray Market underscores the critical role these systems play in modern electrical infrastructure, providing a reliable and efficient means of power distribution that is essential for supporting the energy demands of the future.

| Report Metric | Details |

| Report Name | Electrical Busbar Tray Market |

| Accounted market size in year | US$ 2605 million |

| Forecasted market size in 2031 | US$ 3720 million |

| CAGR | 5.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | ABB, Atkore International, Eaton, Legrand, PUK, Schneider Electric, Chalfant Manufacturing, MP Husky, Oglaend System, Snake Tray, Hoffman, EDP, Vantrunk, Techline Manufacturing, Marco Cable Management, Metsec, Unitrunk, Ellis, Niedax, Chatsworth Products, Panduit, Enduro Composites, EzyStrut, Rittal, OBO |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |