What is Global Busbar Energy Distribution Systems Market?

The Global Busbar Energy Distribution Systems Market is a crucial segment within the electrical infrastructure industry, focusing on the efficient distribution of electrical power. Busbars are metallic strips or bars, typically made of copper, brass, or aluminum, that conduct electricity within a switchboard, distribution board, substation, or other electrical apparatus. They are essential for distributing power with minimal loss and are used in various applications, from residential buildings to large industrial complexes. The market for these systems is driven by the increasing demand for reliable and efficient power distribution solutions, especially in urban areas where space is limited, and energy efficiency is a priority. The systems are designed to handle high current loads and are often preferred over traditional cabling due to their ability to reduce energy loss, improve safety, and offer flexibility in design and installation. As the world continues to urbanize and industrialize, the demand for advanced busbar systems is expected to grow, making them a vital component of modern electrical infrastructure.

Aluminium Tray, Copper Tray in the Global Busbar Energy Distribution Systems Market:

In the Global Busbar Energy Distribution Systems Market, aluminum and copper trays play significant roles due to their distinct properties and applications. Aluminum trays are favored for their lightweight nature and cost-effectiveness. They are particularly advantageous in applications where weight is a critical factor, such as in high-rise buildings or structures where the load-bearing capacity is a concern. Aluminum's natural resistance to corrosion also makes it suitable for outdoor applications or environments with high humidity. Additionally, aluminum trays are easier to handle and install, reducing labor costs and installation time. However, aluminum has a lower conductivity compared to copper, which means that larger cross-sectional areas are required to carry the same current load, potentially increasing the size of the busbar system. On the other hand, copper trays are renowned for their excellent electrical conductivity, which is significantly higher than that of aluminum. This superior conductivity allows for smaller cross-sectional areas to carry the same current load, making copper trays ideal for applications where space is limited, and efficiency is paramount. Copper's high thermal conductivity also aids in better heat dissipation, reducing the risk of overheating and enhancing the overall safety of the electrical system. Despite being heavier and more expensive than aluminum, copper's durability and reliability often justify the higher initial investment, especially in critical applications where performance cannot be compromised. The choice between aluminum and copper trays in busbar systems often depends on the specific requirements of the project, including budget constraints, space availability, and environmental conditions. In some cases, a combination of both materials may be used to optimize performance and cost. For instance, aluminum may be used in less critical areas to save on costs, while copper is employed in high-demand sections to ensure optimal performance. The ongoing advancements in material science and engineering are also contributing to the development of new alloys and coatings that enhance the properties of both aluminum and copper, further expanding their applications in the busbar market. Moreover, the environmental impact of these materials is becoming an increasingly important consideration. Aluminum is often seen as a more sustainable option due to its recyclability and lower carbon footprint during production. However, copper's longer lifespan and superior performance can also contribute to sustainability by reducing energy losses and maintenance requirements over time. As the global focus on sustainability and energy efficiency intensifies, the demand for innovative busbar solutions that balance performance, cost, and environmental impact is expected to rise. In conclusion, both aluminum and copper trays have their unique advantages and challenges in the Global Busbar Energy Distribution Systems Market. The choice between the two often involves a careful evaluation of various factors, including electrical performance, cost, weight, and environmental considerations. As technology continues to evolve, the development of new materials and designs will likely further enhance the capabilities and applications of busbar systems, ensuring their continued relevance in the ever-changing landscape of electrical infrastructure.

Commercial Building, Industrial Building, Others in the Global Busbar Energy Distribution Systems Market:

The Global Busbar Energy Distribution Systems Market finds extensive usage across various sectors, including commercial buildings, industrial buildings, and other applications. In commercial buildings, busbar systems are integral to the efficient distribution of electrical power across multiple floors and sections. These systems are particularly beneficial in high-rise buildings where space constraints and the need for reliable power distribution are critical. Busbars offer a compact and flexible solution that can be easily adapted to the changing needs of commercial spaces, such as offices, shopping malls, and hotels. Their ability to handle high current loads with minimal energy loss makes them an ideal choice for modern commercial infrastructures that demand high efficiency and reliability. In industrial buildings, busbar systems are essential for powering heavy machinery and equipment. Industries such as manufacturing, automotive, and chemical processing require robust and reliable power distribution systems to ensure uninterrupted operations. Busbars provide the necessary durability and efficiency to meet these demands, offering a safe and effective means of distributing power across large industrial complexes. The modular nature of busbar systems also allows for easy expansion and reconfiguration, accommodating the dynamic needs of industrial environments. This flexibility is particularly valuable in industries that undergo frequent changes in production processes or facility layouts. Beyond commercial and industrial buildings, busbar systems are also used in a variety of other applications. These include data centers, where the need for reliable and efficient power distribution is paramount to ensure the continuous operation of servers and other critical equipment. Busbars are also employed in transportation infrastructure, such as airports and railway stations, where they provide a reliable power supply for lighting, signaling, and other essential systems. Additionally, busbars are used in renewable energy installations, such as solar and wind farms, to efficiently distribute the generated power to the grid or storage systems. The versatility and efficiency of busbar systems make them a preferred choice in many applications, contributing to their growing demand in the global market. As the world continues to urbanize and industrialize, the need for advanced power distribution solutions will only increase, driving further innovation and adoption of busbar systems. The ongoing advancements in technology and materials are expected to enhance the performance and capabilities of these systems, ensuring their continued relevance in the evolving landscape of electrical infrastructure.

Global Busbar Energy Distribution Systems Market Outlook:

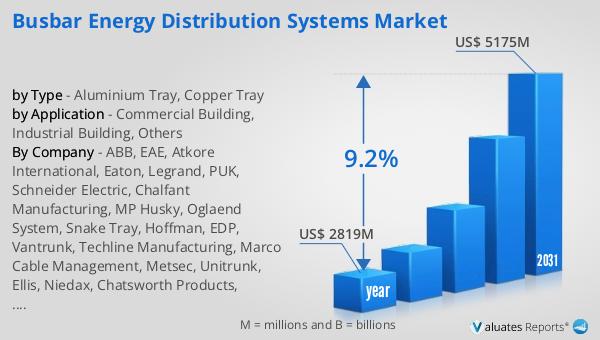

The global market for Busbar Energy Distribution Systems was valued at approximately $2.819 billion in 2024. It is anticipated to grow significantly, reaching an estimated size of $5.175 billion by 2031. This growth represents a compound annual growth rate (CAGR) of 9.2% over the forecast period. This impressive growth trajectory underscores the increasing demand for efficient and reliable power distribution solutions across various sectors. The rising urbanization and industrialization worldwide are key drivers of this market expansion, as they necessitate advanced electrical infrastructure to support growing energy needs. The shift towards renewable energy sources and the emphasis on energy efficiency further contribute to the market's growth, as busbar systems offer a sustainable and efficient means of power distribution. The market's robust growth prospects highlight the critical role of busbar systems in modern electrical infrastructure, as they provide the necessary reliability, efficiency, and flexibility to meet the evolving demands of various industries and applications.

| Report Metric | Details |

| Report Name | Busbar Energy Distribution Systems Market |

| Accounted market size in year | US$ 2819 million |

| Forecasted market size in 2031 | US$ 5175 million |

| CAGR | 9.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | ABB, EAE, Atkore International, Eaton, Legrand, PUK, Schneider Electric, Chalfant Manufacturing, MP Husky, Oglaend System, Snake Tray, Hoffman, EDP, Vantrunk, Techline Manufacturing, Marco Cable Management, Metsec, Unitrunk, Ellis, Niedax, Chatsworth Products, Panduit, Enduro Composites, EzyStrut, Rittal, OBO |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |