What is Global Electrical Arc Furnace (EAF) Smelting Transformers Market?

The Global Electrical Arc Furnace (EAF) Smelting Transformers Market is a specialized segment within the broader electrical equipment industry, focusing on transformers used in electric arc furnaces. These furnaces are crucial in the steelmaking process, where they melt scrap metal using high-voltage electrical arcs. The transformers play a vital role by converting the high-voltage electricity from power lines into the lower voltage required by the furnace. This conversion is essential for maintaining the efficiency and safety of the smelting process. The market for these transformers is driven by the demand for steel, advancements in furnace technology, and the need for energy-efficient solutions. As industries worldwide strive to reduce their carbon footprint, EAF technology, which is generally more environmentally friendly than traditional blast furnaces, is gaining traction. This shift is expected to boost the demand for EAF smelting transformers, making it a dynamic and evolving market. The market's growth is also influenced by regional industrialization trends, government policies on energy consumption, and the global push towards sustainable manufacturing practices. As such, the Global EAF Smelting Transformers Market is poised for significant developments in the coming years.

Direct EAF, Indirect EAF in the Global Electrical Arc Furnace (EAF) Smelting Transformers Market:

Direct and Indirect EAFs are two primary types of electric arc furnaces used in the steelmaking industry, each with distinct operational mechanisms and applications. Direct EAFs are the more common type, where the electric arc is generated directly between the electrodes and the metal charge. This direct contact allows for efficient heat transfer, making the process faster and more energy-efficient. The direct EAF is particularly suited for melting scrap steel, which is a significant advantage given the global emphasis on recycling and sustainability. The process involves charging the furnace with scrap metal, which is then melted by the intense heat of the electric arc. The molten metal is then refined and alloyed to produce the desired steel grade. Direct EAFs are known for their flexibility, as they can be quickly started and stopped, allowing steelmakers to adjust production according to demand. This flexibility is crucial in today's fast-paced market environment, where demand can fluctuate rapidly. On the other hand, Indirect EAFs operate differently. In these furnaces, the electric arc is not in direct contact with the metal charge. Instead, the arc is formed between the electrodes, and the heat is transferred to the metal through radiation and convection. This indirect method is generally slower and less efficient than the direct method, but it offers certain advantages. For instance, indirect EAFs can be used to melt materials that are sensitive to direct arc exposure, such as certain alloys and non-ferrous metals. This makes them suitable for specialized applications where the quality and properties of the final product are critical. Indirect EAFs are also used in processes where the control of the atmosphere within the furnace is essential, such as in the production of high-purity metals. The choice between direct and indirect EAFs depends on several factors, including the type of material being processed, the desired properties of the final product, and the specific requirements of the production process. Both types of furnaces have their place in the global EAF smelting transformers market, catering to different segments of the steel and metal industries. As technology advances, we can expect further innovations in both direct and indirect EAFs, enhancing their efficiency, reducing energy consumption, and expanding their range of applications. The ongoing research and development in this field are likely to lead to new furnace designs and transformer technologies that will further optimize the smelting process. This will not only benefit the steel industry but also contribute to broader efforts to improve energy efficiency and reduce environmental impact in industrial processes.

Smelt, Heat Treatment, Others in the Global Electrical Arc Furnace (EAF) Smelting Transformers Market:

The Global Electrical Arc Furnace (EAF) Smelting Transformers Market finds its applications in various areas, including smelting, heat treatment, and other specialized processes. In the smelting process, EAFs are primarily used to melt scrap metal and convert it into molten steel. This process is crucial for recycling metal waste and producing new steel products. The transformers in EAFs are responsible for converting high-voltage electricity into the lower voltage required for the furnace operation. This conversion is essential for maintaining the efficiency and safety of the smelting process. The use of EAFs in smelting is particularly advantageous due to their ability to quickly melt large quantities of scrap metal, making them ideal for high-volume production environments. Additionally, EAFs offer flexibility in terms of the types of scrap metal that can be processed, allowing steelmakers to produce a wide range of steel grades and products. In the area of heat treatment, EAFs are used to alter the physical and chemical properties of metals. This process involves heating the metal to a specific temperature and then cooling it at a controlled rate. The transformers in EAFs play a crucial role in providing the precise voltage and current required for the heat treatment process. This precision is essential for achieving the desired properties in the final product, such as hardness, strength, and ductility. Heat treatment is a critical step in the production of high-quality steel products, and the use of EAFs in this process ensures that the metal is treated uniformly and efficiently. The ability to control the heating and cooling rates in EAFs allows for the production of steel with specific characteristics, making them suitable for a wide range of applications, from construction to automotive manufacturing. Beyond smelting and heat treatment, EAFs are also used in other specialized processes, such as the production of high-purity metals and alloys. In these applications, the transformers in EAFs are essential for maintaining the precise control of the furnace environment, ensuring that the final product meets the required specifications. The ability to produce high-purity metals is particularly important in industries such as electronics and aerospace, where the quality and performance of the materials are critical. EAFs offer the flexibility and precision needed to produce these specialized materials, making them an invaluable tool in modern manufacturing. As industries continue to evolve and demand for high-quality materials increases, the role of EAFs in these specialized processes is likely to grow, further driving the demand for advanced smelting transformers.

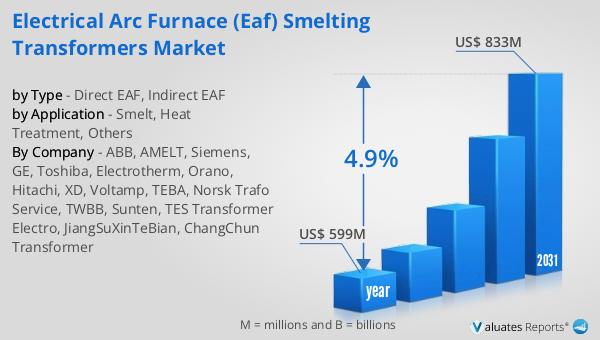

Global Electrical Arc Furnace (EAF) Smelting Transformers Market Outlook:

In 2024, the global market for Electrical Arc Furnace (EAF) Smelting Transformers was valued at approximately $599 million. This market is projected to expand significantly, reaching an estimated size of $833 million by 2031. This growth represents a compound annual growth rate (CAGR) of 4.9% over the forecast period. The increasing demand for steel, coupled with advancements in EAF technology, is driving this growth. As industries worldwide seek more sustainable and energy-efficient manufacturing processes, EAFs are becoming increasingly popular. These furnaces offer a more environmentally friendly alternative to traditional blast furnaces, as they primarily use recycled scrap metal as their raw material. This not only reduces the need for virgin materials but also lowers greenhouse gas emissions associated with steel production. The market's expansion is also supported by regional industrialization trends and government policies promoting energy efficiency and sustainability. As a result, the demand for EAF smelting transformers is expected to rise, providing opportunities for manufacturers and suppliers in this market. The ongoing research and development in transformer technology are likely to lead to further innovations, enhancing the efficiency and performance of EAFs and supporting the market's growth.

| Report Metric | Details |

| Report Name | Electrical Arc Furnace (EAF) Smelting Transformers Market |

| Accounted market size in year | US$ 599 million |

| Forecasted market size in 2031 | US$ 833 million |

| CAGR | 4.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | ABB, AMELT, Siemens, GE, Toshiba, Electrotherm, Orano, Hitachi, XD, Voltamp, TEBA, Norsk Trafo Service, TWBB, Sunten, TES Transformer Electro, JiangSuXinTeBian, ChangChun Transformer |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |