What is Robot Aseptic Filling Equipment - Global Market?

Robot Aseptic Filling Equipment is a specialized machinery used in the global market to ensure the sterile packaging of products without human intervention. This equipment is crucial in industries where maintaining sterility is paramount, such as pharmaceuticals, food, and cosmetics. The technology behind robot aseptic filling involves automated systems that fill containers with products in a sterile environment, minimizing the risk of contamination. This process is essential for products that require a long shelf life and must remain free from microbial contamination. The global market for this equipment is expanding as industries increasingly prioritize hygiene and efficiency. The demand for robot aseptic filling equipment is driven by the need for high precision, reduced human error, and compliance with stringent health regulations. As industries continue to innovate and expand, the role of robot aseptic filling equipment becomes even more significant, ensuring that products are safe for consumption and use. The market's growth is also fueled by advancements in technology, making these systems more accessible and efficient for various applications.

Fully Automatic, Semi-Automatic in the Robot Aseptic Filling Equipment - Global Market:

In the realm of robot aseptic filling equipment, the distinction between fully automatic and semi-automatic systems is significant, each offering unique advantages and catering to different operational needs. Fully automatic aseptic filling equipment is designed to operate with minimal human intervention, providing a seamless and efficient process from start to finish. These systems are equipped with advanced robotics and sensors that ensure precise filling, capping, and sealing of containers in a sterile environment. The primary advantage of fully automatic systems is their ability to handle large volumes of production with consistent accuracy and speed. They are ideal for large-scale manufacturing facilities where high throughput and minimal downtime are critical. The integration of sophisticated software allows for real-time monitoring and adjustments, ensuring optimal performance and product quality. On the other hand, semi-automatic aseptic filling equipment requires some level of human involvement, typically in the setup, monitoring, and occasional manual adjustments during the filling process. These systems are often more flexible and can be adapted to handle a variety of container sizes and product types. Semi-automatic systems are particularly beneficial for smaller production runs or facilities with limited space and budget constraints. They offer a balance between automation and manual control, allowing operators to intervene when necessary to ensure product quality and compliance with safety standards. While they may not match the speed and efficiency of fully automatic systems, semi-automatic equipment provides a cost-effective solution for businesses looking to enhance their aseptic filling capabilities without a significant investment. Both fully automatic and semi-automatic systems play a crucial role in the global market for robot aseptic filling equipment, catering to the diverse needs of industries such as pharmaceuticals, food and beverage, and cosmetics. As technology continues to evolve, these systems are becoming more sophisticated, offering enhanced features such as improved precision, reduced energy consumption, and greater adaptability to different production environments. The choice between fully automatic and semi-automatic systems ultimately depends on the specific requirements of the production process, including factors such as production volume, budget, and the level of automation desired. In conclusion, the global market for robot aseptic filling equipment is characterized by a dynamic interplay between fully automatic and semi-automatic systems, each offering distinct benefits and addressing different operational needs. As industries continue to prioritize hygiene, efficiency, and product quality, the demand for these systems is expected to grow, driving further innovation and development in the field.

Cosmetic, Drug, Food, Others in the Robot Aseptic Filling Equipment - Global Market:

Robot aseptic filling equipment finds extensive usage across various industries, including cosmetics, pharmaceuticals, food, and others, due to its ability to maintain sterility and precision in the packaging process. In the cosmetics industry, this equipment is essential for packaging products such as creams, lotions, and serums, where maintaining product integrity and preventing contamination are crucial. The use of robot aseptic filling systems ensures that these products are packaged in a sterile environment, preserving their quality and extending their shelf life. In the pharmaceutical sector, aseptic filling equipment is indispensable for the packaging of sterile drugs, vaccines, and other medical products. The precision and reliability of robotic systems ensure that these products are filled and sealed in a contamination-free environment, meeting stringent regulatory standards and ensuring patient safety. The food industry also benefits significantly from robot aseptic filling equipment, particularly in the packaging of perishable and ready-to-eat products. By maintaining a sterile environment during the filling process, these systems help extend the shelf life of food products and reduce the risk of spoilage and contamination. This is particularly important for products such as dairy, juices, and canned foods, where maintaining freshness and quality is paramount. Beyond these primary industries, robot aseptic filling equipment is also utilized in other sectors, such as biotechnology and chemical manufacturing, where maintaining sterility and precision is critical. The versatility and adaptability of these systems make them suitable for a wide range of applications, ensuring that products are packaged safely and efficiently. As industries continue to evolve and prioritize hygiene and efficiency, the demand for robot aseptic filling equipment is expected to grow, driving further innovation and development in the field.

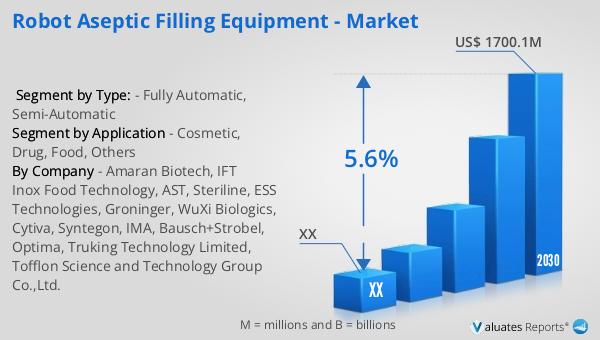

Robot Aseptic Filling Equipment - Global Market Outlook:

The global market for Robot Aseptic Filling Equipment was valued at approximately $1,176 million in 2023 and is projected to reach an adjusted size of $1,700.1 million by 2030, reflecting a compound annual growth rate (CAGR) of 5.6% during the forecast period from 2024 to 2030. This growth is largely attributed to the continuous advancements and applications of aseptic packaging technology, which is increasingly being adopted across various industries. Aseptic packaging is becoming more prevalent in sectors such as pharmaceuticals, cosmetics, food seasonings, and canned goods due to its ability to maintain product sterility and extend shelf life. The rising demand for safe and hygienic packaging solutions is driving the expansion of the robot aseptic filling equipment market. As industries continue to innovate and prioritize product safety and quality, the role of aseptic filling technology becomes even more critical. The market's growth is also supported by technological advancements that enhance the efficiency and accessibility of these systems, making them an integral part of modern manufacturing processes. With the ongoing development of aseptic packaging technology, its application is expected to broaden, further fueling the growth of the global market for robot aseptic filling equipment.

| Report Metric | Details |

| Report Name | Robot Aseptic Filling Equipment - Market |

| Forecasted market size in 2030 | US$ 1700.1 million |

| CAGR | 5.6% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Amaran Biotech, IFT Inox Food Technology, AST, Steriline, ESS Technologies, Groninger, WuXi Biologics, Cytiva, Syntegon, IMA, Bausch+Strobel, Optima, Truking Technology Limited, Tofflon Science and Technology Group Co.,Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |