What is Precision Polishing Equipment - Global Market?

Precision polishing equipment is a specialized tool used in various industries to achieve a high level of surface finish and dimensional accuracy on different materials. This equipment is essential in processes where even the slightest surface imperfections can lead to significant performance issues or failures. The global market for precision polishing equipment is driven by the increasing demand for high-quality finishes in industries such as automotive, aerospace, electronics, and medical devices. These machines are designed to remove material from a workpiece with extreme precision, often using abrasive particles or chemical-mechanical polishing techniques. The equipment can vary from simple hand-held devices to complex automated systems, depending on the application and required precision. The market is characterized by continuous technological advancements aimed at improving efficiency, reducing operational costs, and enhancing the quality of the finished product. As industries continue to demand higher precision and better surface finishes, the market for precision polishing equipment is expected to grow, driven by innovations and the need for more sophisticated manufacturing processes.

Rotary, Dual Action in the Precision Polishing Equipment - Global Market:

Rotary and dual-action polishing machines are two prominent types of precision polishing equipment widely used in the global market. Rotary polishers are known for their circular motion, where the pad spins on a single axis. This type of motion is effective for removing significant imperfections and is often used in applications requiring substantial material removal. Rotary polishers are favored in industries like automotive, where they are used to restore paintwork by eliminating scratches and oxidation. However, they require skilled operation to avoid creating swirl marks or damaging the surface due to their aggressive nature. On the other hand, dual-action polishers combine rotary and orbital motions, providing a more versatile and user-friendly option. The dual-action mechanism reduces the risk of surface damage, making it suitable for both beginners and professionals. This type of polisher is ideal for achieving a fine finish and is commonly used in applications where precision and surface quality are paramount, such as in aerospace and electronics. The dual-action polisher's ability to oscillate while spinning allows for even distribution of pressure and heat, minimizing the risk of overheating and ensuring a consistent finish. In the global market, the choice between rotary and dual-action polishers depends on the specific requirements of the application, including the material being polished, the desired finish, and the operator's skill level. As industries continue to demand higher precision and better surface finishes, manufacturers are investing in research and development to enhance the capabilities of both rotary and dual-action polishers. This includes the integration of advanced technologies such as digital controls, automated systems, and improved abrasive materials to achieve superior results. The global market for precision polishing equipment is also influenced by the growing trend towards automation and smart manufacturing. Automated polishing systems are becoming increasingly popular, offering consistent quality, reduced labor costs, and increased production efficiency. These systems often incorporate both rotary and dual-action polishing techniques, allowing for flexibility and adaptability in various applications. Furthermore, the development of eco-friendly and sustainable polishing solutions is gaining traction in the market. Manufacturers are focusing on reducing the environmental impact of polishing processes by developing equipment that uses less energy, produces less waste, and utilizes environmentally friendly abrasives. This trend is driven by increasing regulatory pressures and the growing awareness of sustainability issues among consumers and industries. In conclusion, rotary and dual-action polishers play a crucial role in the precision polishing equipment market, each offering unique advantages and applications. The choice between the two depends on factors such as the level of precision required, the material being polished, and the operator's expertise. As the demand for high-quality finishes continues to rise across various industries, the market for precision polishing equipment is expected to grow, driven by technological advancements, automation, and sustainability initiatives.

Automotive, Military and Aerospace, Medical Instruments, Manufacturing, Others in the Precision Polishing Equipment - Global Market:

Precision polishing equipment finds extensive usage across various sectors, including automotive, military and aerospace, medical instruments, manufacturing, and others. In the automotive industry, precision polishing equipment is crucial for achieving high-quality finishes on vehicle components, such as body panels, headlights, and interior parts. The equipment helps in removing imperfections, enhancing the aesthetic appeal, and ensuring the longevity of the components. In the military and aerospace sectors, precision polishing is vital for maintaining the performance and reliability of critical components. Aircraft parts, such as turbine blades and engine components, require precise surface finishes to ensure optimal performance and safety. Precision polishing equipment is used to achieve the necessary surface quality, reducing the risk of failure and extending the lifespan of these components. In the medical instruments industry, precision polishing equipment is essential for manufacturing devices that require high levels of cleanliness and precision, such as surgical instruments and implants. The equipment ensures that these devices meet stringent quality standards, minimizing the risk of contamination and improving patient outcomes. In the manufacturing sector, precision polishing equipment is used to enhance the quality and performance of various products, from consumer electronics to industrial machinery. The equipment helps in achieving the desired surface finish, improving the functionality and durability of the products. Additionally, precision polishing equipment is used in other industries, such as jewelry and optics, where high-quality finishes are essential for product performance and aesthetic appeal. Overall, the usage of precision polishing equipment in these areas highlights its importance in achieving high-quality finishes and ensuring the performance and reliability of critical components.

Precision Polishing Equipment - Global Market Outlook:

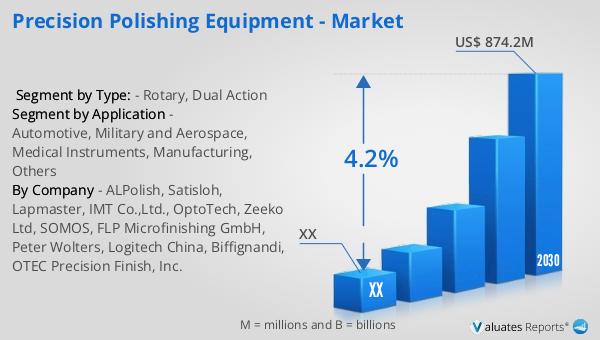

The global market for precision polishing equipment was valued at approximately $654 million in 2023. It is projected to grow to a revised size of $874.2 million by 2030, reflecting a compound annual growth rate (CAGR) of 4.2% during the forecast period from 2024 to 2030. This growth is driven by the increasing demand for high-quality finishes across various industries, including automotive, aerospace, electronics, and medical devices. However, the market faces challenges, such as the decline in the construction machinery industry's operating income, which dropped by more than 12% in 2022, according to the China Machinery Industry Federation. This decline may impact the demand for precision polishing equipment in the construction sector, as companies may reduce investments in new equipment due to financial constraints. Despite these challenges, the overall market outlook remains positive, with technological advancements and the growing trend towards automation and sustainability expected to drive growth. Manufacturers are focusing on developing innovative solutions to meet the evolving needs of industries, ensuring that precision polishing equipment remains a critical tool for achieving high-quality finishes and enhancing the performance and reliability of products.

| Report Metric | Details |

| Report Name | Precision Polishing Equipment - Market |

| Forecasted market size in 2030 | US$ 874.2 million |

| CAGR | 4.2% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | ALPolish, Satisloh, Lapmaster, IMT Co.,Ltd., OptoTech, Zeeko Ltd, SOMOS, FLP Microfinishing GmbH, Peter Wolters, Logitech China, Biffignandi, OTEC Precision Finish, Inc. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |