What is Global Warehouse Robots Market?

The Global Warehouse Robots Market refers to the industry focused on the development, production, and deployment of robotic systems designed to automate various tasks within warehouses. These robots are engineered to enhance efficiency, accuracy, and productivity in warehouse operations, which include tasks such as picking, sorting, packing, and transporting goods. The market has been experiencing significant growth due to the increasing demand for automation in logistics and supply chain management. This demand is driven by the need to reduce operational costs, improve order accuracy, and meet the rising consumer expectations for faster delivery times. Warehouse robots come in various forms, including mobile robots, fixed robots, and collaborative robots, each serving specific functions within the warehouse environment. As technology advances, these robots are becoming more sophisticated, with capabilities such as machine learning and artificial intelligence, enabling them to perform complex tasks and adapt to dynamic environments. The market is also influenced by factors such as labor shortages, the growth of e-commerce, and the need for efficient inventory management. Overall, the Global Warehouse Robots Market is a dynamic and rapidly evolving sector that plays a crucial role in modernizing warehouse operations and enhancing supply chain efficiency.

Mobile Robots, Fixed Robots in the Global Warehouse Robots Market:

Mobile robots and fixed robots are two primary categories within the Global Warehouse Robots Market, each offering distinct functionalities and advantages. Mobile robots, often referred to as autonomous mobile robots (AMRs), are designed to navigate warehouse environments independently. They are equipped with sensors, cameras, and advanced software that allow them to move around obstacles, follow designated paths, and transport goods from one location to another. These robots are highly flexible and can be easily integrated into existing warehouse systems without the need for significant infrastructure changes. Mobile robots are particularly beneficial in dynamic environments where the layout frequently changes, as they can adapt to new configurations and optimize their routes for efficiency. They are commonly used for tasks such as order picking, inventory management, and material handling, significantly reducing the time and labor required for these operations. On the other hand, fixed robots, also known as stationary robots, are typically installed in a fixed location within the warehouse. These robots are often used for repetitive tasks that require high precision and speed, such as sorting, packing, and palletizing. Fixed robots are usually equipped with robotic arms and end-effectors that can handle various types of products with accuracy and consistency. They are ideal for high-volume operations where the same task needs to be performed continuously over long periods. While fixed robots require more initial setup and infrastructure, they offer unmatched speed and reliability for specific tasks. Both mobile and fixed robots contribute to the overall efficiency of warehouse operations, but their applications and benefits vary depending on the specific needs and layout of the warehouse. As technology continues to advance, the integration of mobile and fixed robots is becoming more seamless, allowing warehouses to leverage the strengths of both types of robots to achieve optimal performance. The choice between mobile and fixed robots often depends on factors such as the size of the warehouse, the nature of the products being handled, and the specific operational goals of the business. In many cases, a combination of both mobile and fixed robots is used to create a hybrid system that maximizes efficiency and flexibility. This approach allows warehouses to automate a wide range of tasks, from simple material transport to complex order fulfillment processes. As the Global Warehouse Robots Market continues to grow, the development of new technologies and innovations is expected to further enhance the capabilities of both mobile and fixed robots, making them even more integral to modern warehouse operations.

E-commerce, Automotive, Food & Beverages, Electronics, Other in the Global Warehouse Robots Market:

The usage of robots in the Global Warehouse Robots Market spans across various industries, each benefiting from the automation and efficiency that these robots bring. In the e-commerce sector, warehouse robots play a crucial role in managing the high volume of orders and ensuring timely delivery. With the rapid growth of online shopping, e-commerce companies are under pressure to process orders quickly and accurately. Warehouse robots help streamline operations by automating tasks such as picking, packing, and sorting, which reduces the time and labor required to fulfill orders. This not only improves efficiency but also enhances customer satisfaction by ensuring faster delivery times. In the automotive industry, warehouse robots are used to manage the complex supply chains and inventory systems. The automotive sector requires precise and efficient handling of parts and components, and robots are ideal for tasks such as sorting, transporting, and assembling. By automating these processes, automotive companies can reduce errors, improve productivity, and maintain a smooth flow of materials throughout the supply chain. In the food and beverages industry, warehouse robots are used to handle perishable goods and ensure proper storage and distribution. These robots help maintain the quality and safety of food products by automating tasks such as sorting, packing, and palletizing. This reduces the risk of contamination and spoilage, ensuring that products reach consumers in optimal condition. In the electronics industry, warehouse robots are used to manage the intricate and delicate components that require careful handling. Robots are ideal for tasks such as picking and placing small parts, assembling components, and testing finished products. By automating these processes, electronics companies can improve precision, reduce waste, and increase production efficiency. Other industries, such as pharmaceuticals and retail, also benefit from the use of warehouse robots. In the pharmaceutical industry, robots are used to handle sensitive and high-value products, ensuring accurate and secure storage and distribution. In the retail sector, robots help manage inventory and streamline order fulfillment processes, improving efficiency and customer satisfaction. Overall, the Global Warehouse Robots Market is transforming the way industries operate by providing innovative solutions that enhance efficiency, accuracy, and productivity. As technology continues to advance, the adoption of warehouse robots is expected to increase across various sectors, further driving the growth of the market.

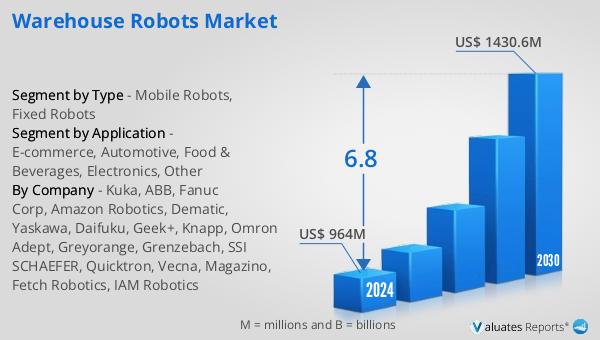

Global Warehouse Robots Market Outlook:

The outlook for the Global Warehouse Robots Market indicates a promising growth trajectory. The market is anticipated to expand from $964 million in 2024 to $1,430.6 million by 2030, reflecting a compound annual growth rate (CAGR) of 6.8% over the forecast period. This growth is driven by the increasing demand for automation in warehouse operations, as businesses seek to improve efficiency, reduce costs, and meet the rising expectations for faster delivery times. Kuka, a leading manufacturer in the market, holds a significant position with its revenue accounting for over 20% of the global market share. This highlights the company's strong presence and influence in the industry. Additionally, North America emerges as the largest regional market, contributing more than 39% to the global revenue. This dominance can be attributed to the region's advanced technological infrastructure, high adoption rate of automation solutions, and the presence of major e-commerce and logistics companies. The growth of the Global Warehouse Robots Market is further supported by factors such as labor shortages, the expansion of e-commerce, and the need for efficient inventory management. As businesses continue to invest in automation technologies, the market is expected to witness significant advancements in robot capabilities, including the integration of artificial intelligence and machine learning. These innovations will enable robots to perform more complex tasks and adapt to dynamic environments, further enhancing their value in warehouse operations. Overall, the Global Warehouse Robots Market presents a dynamic and evolving landscape, with opportunities for growth and innovation across various industries and regions.

| Report Metric | Details |

| Report Name | Warehouse Robots Market |

| Accounted market size in 2024 | US$ 964 million |

| Forecasted market size in 2030 | US$ 1430.6 million |

| CAGR | 6.8 |

| Base Year | 2024 |

| Forecasted years | 2025 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | Kuka, ABB, Fanuc Corp, Amazon Robotics, Dematic, Yaskawa, Daifuku, Geek+, Knapp, Omron Adept, Greyorange, Grenzebach, SSI SCHAEFER, Quicktron, Vecna, Magazino, Fetch Robotics, IAM Robotics |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |